FAILURE TO OPERATE

Should the burner fail to light, the control will perform two

more ignition trials prior to entering a lockout state (flash-

ing “LOC”). Note that each subsequent ignition trial will

not occur immediately. After a failed ignition trial, the

blower must run for approximately 10 seconds to purge

the system, then the ignitor element must complete a 30

second warm-up period. Therefore, a time period of

approximately 40 to 90 seconds will expire between each

ignition trial. If the burner lights during any one of these

three ignition trials, normal operation will resume. If the

burner lights, but goes off in about 4 seconds, check the

polarity of the wiring. See electrical on page 6. If the

burner does not light after the third ignition trial, the

control will enter a lockout state. This lockout state

indicates that a problem exists with either the appli-

ance, the controls, or the gas supply. Under such cir-

cumstances, a qualified service technician should be

contacted immediately to properly service the appliance

and correct the problem. If a technician is not available,

depressing the red button once will remove the lockout

state so additional trials for ignition can be performed.

Any time flashing double zero’s are shown, you must

look for an LED out, or flashing. The LED that is out

or flashing will assist you in diagnosing lock out con-

dition.

FUEL CONVERSIONS

This product may be converted from L.P. gas (propane)

to Natural gas or from Natural gas to L.P. gas (propane).

For information and requirements about this procedure

call the Technical Service Department at 1-800-432-

8373.

Should overheating occur or the gas supply fail to shut

off, turn off the manual gas control valve to the appliance.

DO NOT use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace the water heater if

the control system or any gas control which has been

under water.

CORROSIVE ATMOSPHERES

The heater should not be installed near an air supply con-

taining halogenated hydrocarbons. For example, the air

in beauty salons, dry cleaning establishments, photo pro-

cessing labs, and storage areas for liquid and powdered

bleaches or swimming pool chemicals often contain

hydrocarbons. The air there may be safe to breathe, but

when it passes through a gas flame, corrosive elements

are released that will shorten the life of any gas burning

appliance. Propellants from common spray cans or gas

leaks from refrigeration equipment are highly corrosive

after passing through a flame. The limited warranty is

voided when failure of water heater is due to a corrosive

atmosphere. (Reference is made to the limited warranty

for complete terms and conditions.)

CONDENSATE

This is a condensing high efficiency appliance, therefore

this unit has a condensate removal system. Condensate

is nothing more than water vapor, derived from the com-

bustion products, similar to an automobile when it is ini-

tially started. This condensate does have a low pH and

should be treated with a condensate filter. This filter con-

tains either lime crystals or marble crystals, which will

neutralize the condensate. The outlet of the filter is sized

for 5/8" ID (inside diameter) plastic tubing. It is very

important that the condensate line is sloped away from

and down to a suitable inside drain. If the condensate

outlet on the AdvantagePlus is lower than the drain, you

must use a condensate removal pump. It is also very

important that the condensate line is not exposed to

freezing temperatures, or any other type of blockage.

Plastic tubing should be the only material used for the

condensate line. Steel, brass, copper, or other metals will

be subject to corrosion and deterioration. A second vent

may be necessary to prevent condensate line vacuum

lock if a long horizontal run is used. Also an increase to

1" tubing may be necessary.

NOTE: Always check local codes for proper

evacuation of condensate.

13

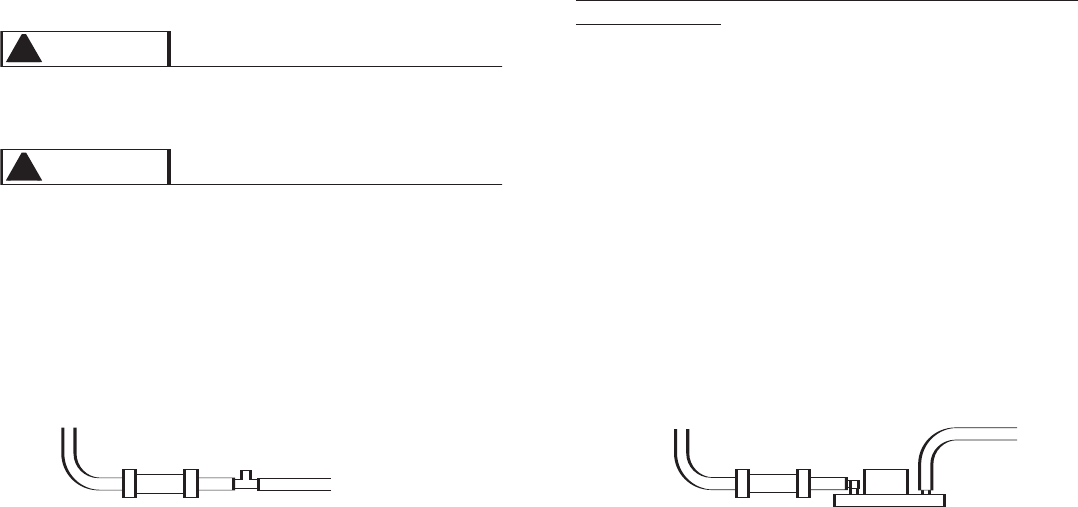

INSTALLATION OF A CONDENSATE NEUTRALIZER AND PUMP (Not Supplied)

CONDENSATE LINE CONDENSATE LINE WITH PUMP

TO DRAIN

TO DRAIN

FROM ADVANTAGE PLUS

FROM ADVANTAGE PLUS

CONDENSATE LINE MUST BE PITCHED AT LEAST 1/4" PER FOOT TO PROPERLY DRAIN.

IF THIS CANNOT BE DONE OR A VERY LONG LENGTH OF CONDENSATE HOSE IS USED

YOU MUST INCREASE THE CONDENSATE HOSE TO A MINIMUM OF 1" I.D. AND PLACE A

TEE IN THE LINE AFTER THE CONDENSATE NEUTRALIZER TO PROPERLY REDUCE

VACUUM LOCK IN THE DRAIN LINE.

CONTACT YOUR LOCAL WHOLESALE PLUMBING SUPPLY

STORE FOR MORE INFORMATION ON CONDENSATE

NEUTRALIZERS AND PUMPS

WARNING

!

WARNING

!