14

8. After checking that all connections are tight and the drain

valve near the bottom of the water heater is closed, go to

“Filling the Water Heater”.

SECTION B

COPPER (SWEAT) PIPING

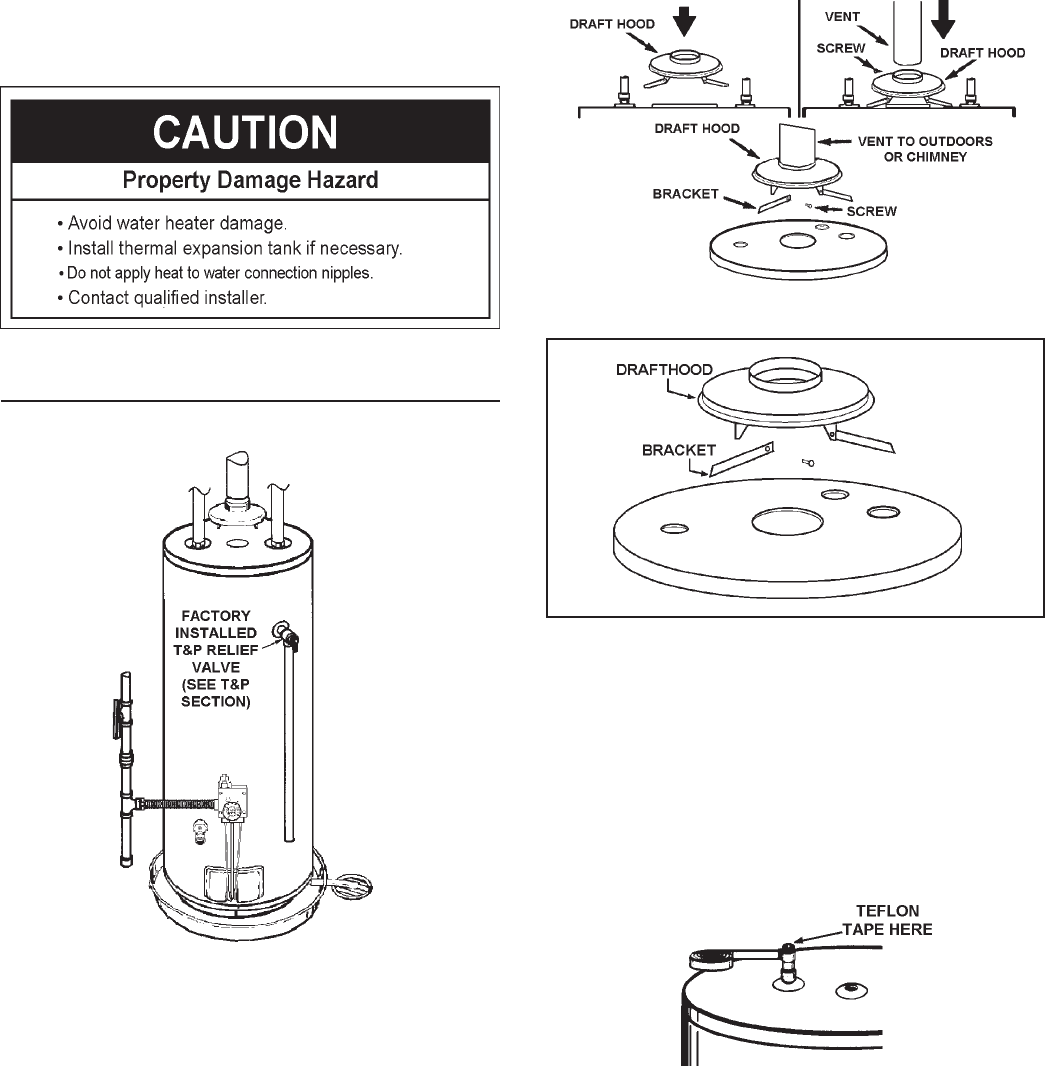

(See Figure 19)

FIGURE 19.

1. Position the water heater so that the existing piping will

require the shortest distance between connections. Make

sure that you are able to reach the drain valve and all

connections when the water heater is in place. This will

make it easy to service the water heater. The water heater

must be level before you begin the piping.

If a water heater is installed in a closed water supply

system, such as one having a back-flow preventer, check

valve, water meter with check valve, etc. . . in the cold water

supply, means shall be provided to control thermal

expansion. Contact the water supplier or plumbing

contractor on how to control this situation.

2. Place the draft hood in the receiving holes where it

connects to the water heater. The legs should snap in to

give a tight fit.

Secure the legs of the draft hood with the supplied draft

hood brackets, see Figures 20 AND 20A.

FIGURE 20.

FIGURE 20A.

3. Place the vent pipe over the draft hood. With the vent pipe

in position, drill a small hole through both the vent pipe

and draft hood. Secure them together with a sheet metal

screw.

4. Put two or three turns of teflon tape or pipe joint compound

around the exposed end of the 1” NPT threaded nipples

for 75 gallon models or 1.25” NPT threaded nipples for

100 gallon models, see Figure 21.

FIGURE 21.

5. Cutting custom lengths of copper pipe will be needed in

this procedure. The pipe cutter is simple to use, screw

the adjustment knob until the opening of the jaws will

allow the cutters to be placed around the pipe. Then close

the adjustment until the cutting blade is just tight against

the pipe. Do not over tighten. Make one or two revolutions

of the cutter around the pipe. Tighten the adjustment knob

slightly, and revolve the cutters around the pipe once again.

Continue this procedure until the pipe is completely cut in

two.

6. Cleaning and brushing the piping and fittings is one of

the most important aspects of sweat connections. Clean

the ends of each piece of copper pipe with emery cloth as