9

10

4

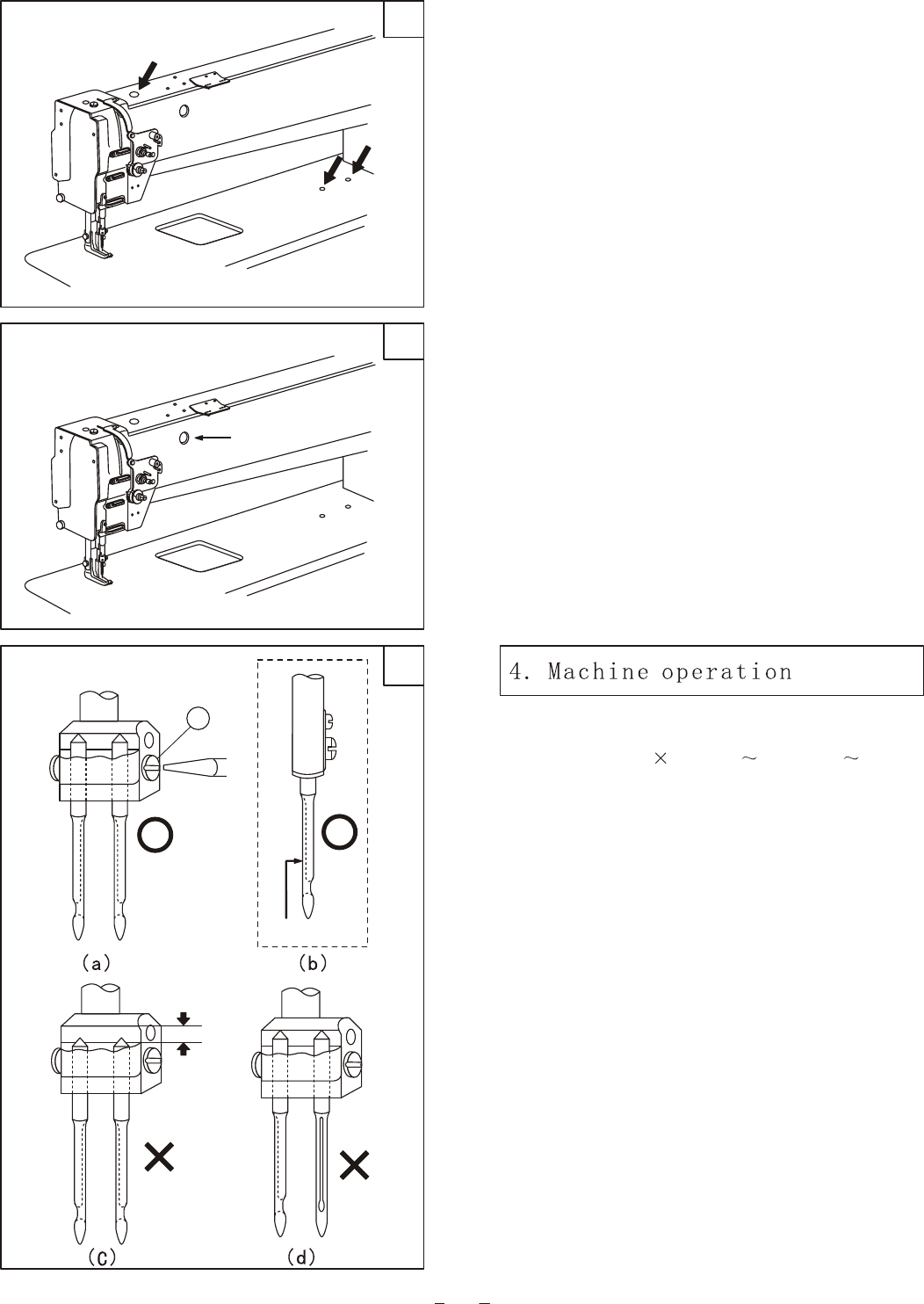

11

A

B. When the machine starts for initial time or reuse

after a long time, the proper oil amount should be filled

in the sections of machine shown by arrows in Fig. 8,9.

When it is in operation, please observe the oil sparking

in oil screen to check the oil condition. .

.

.

.

.

C. When a new machine starts running, for extending its

lift, please run at a medium and low speed (1000s.p.m)

for about a month and then raise the speed gradually.

D. Please turn off the power when it is not in use or the

operator leaves away from it.

E. Replace the oil every month, when replacing, fully

drain off the old oil in the oil pan and add the new one.

F. For MSK-8420BL-18, the needle gauge options are: 6.4,

3.2,4,4.8,8,9.5,12.7,16,19,24.5mm. To get it, the needle

plate, inner and outer presser foot, needle holder, feed

dog, left and right sliding plate, thread guide should be

changed, the standard needle gauge is 6.4mm, for the

other needle gauge, the relevant parts can be ordered

from the factory.

1. Coordination among needle, thread and materials

Please use needle DP 17 or 135 17, Nm125 180, the

coarseness of needle should be in accordance with the

nature of materials. If stitching on heavy weight

materials with a slim needle, the needle will be broken

easily. Needle skipping or thread breakage will also

occur. On the contrary, stitch on tightly materials with a

very coarse needle, the materials will be destroyed

because of over-big needle hole, so the needle and

thread should be properly selected. .

2. Install the needle (Fig. 11)

Turn the hand wheel to lift the needle bar to its highest

position, loosen the needle set screw A, fully insert the

needle shank up to the bottom of needle holder, keep the

long grooves of the two needles opposite with each

other, then tighten the set screw as shown in Fig.(a), For

single needle, keep the long groove of needle facing the

left of the operator as shown in Fig.(b).

Note: Fig.(c) insufficient insertion or Fig. (D) wrong

direction of needle groove is incorrect.

.

.

Oil screen

Single

needle

Clearance

Long groove leftward