8

24

22

23

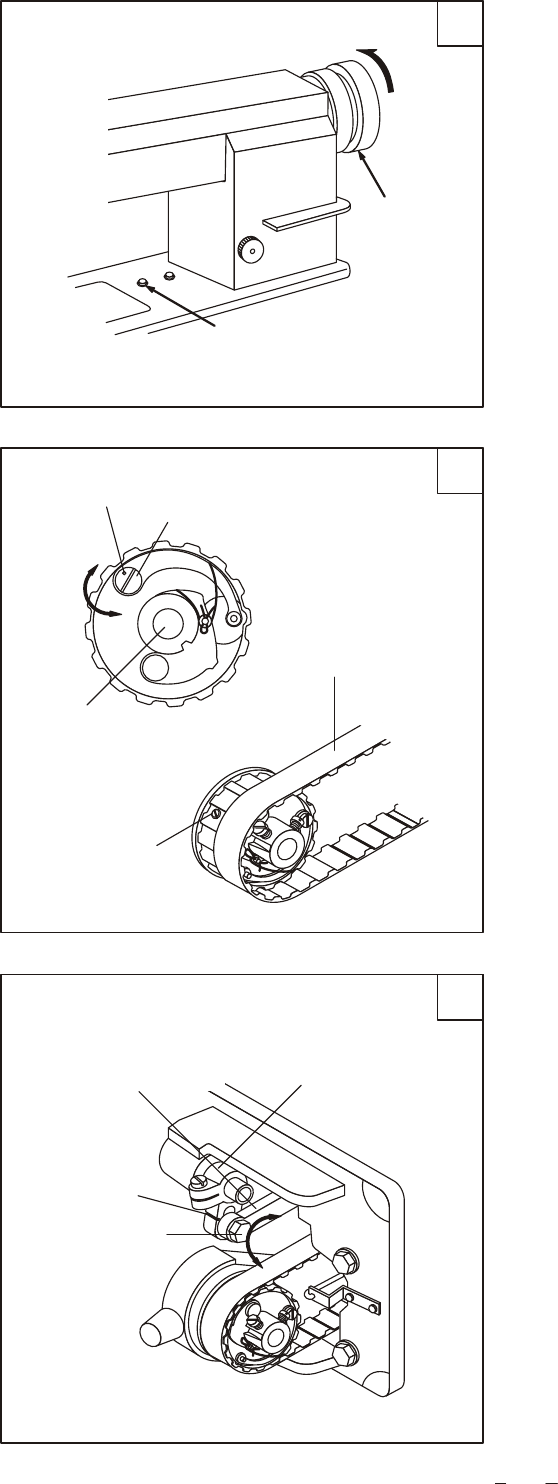

3.2 How to reset the safety clutch device (Fig.22)

A. While press down the button on the bed surface with

left hand, turn the hand wheel slowly with right hand in

the direction shown in Fig. 22 (clockwise).

B. When the stopper brakes the hand wheel, more

strength is needed to turn the balance wheel to reset the

safety clutch device.

C. Release the button.

D. So the resetting is OK and put the bobbin into hook.

(See Fig.15)

.

.

.

.

3.3 How to adjust the strength on the safety clutch

device (Fig.23)

A. When the white mark of the eccentric pin aims at the

centre of the lower shaft, indicates that the strength on

the safety clutch is the minimum. When the white mark

points outward, the strength is properly increased.

B. For adjusting the strength of it, move the belt and

loosen the set screw of eccentric pin, and turn the

eccentric pin.

C. After adjustment, please tighten the set screw.

.

.

.

3.4 Adjust the upper feed mechanism (Fig.23)

If the upper and lower feed are not in timing during

sewing, the long hole of the horizontal feed crank(right)

should be adjusted to get the length of upper feed.

Adjusting as follows:

A. Loosen the special stud.

B. Move the stud upward to decrease the amount of

upper feed.

C. Move the stud downward to increase the amount of

upper feed. Theoretically, when it is on the reference

line of the horizontal feed crank, the upper feed amount

equals to the lower feed amount.

D. After adjustment, tighten the special stud.

.

.

.

.

.

.

Handwheel

Button

White mark

Eccentric pin

Belt

Tighten

Loosen

Lower shaft

Set screw

Link

Horizontal shaft crank (right)

Reference line

Special stud

Upper layer feed decreaseUpper layer feed decreaseUpper layer feed decrease

Upper layer feed increaseUpper layer feed increaseUpper layer feed increase