Models with Motorized Modulation: H2, H6, W2

Sizes 2100-4001 are equipped with a single motorized modulating valve controlled by a temperature

controller that offers full modulation down to 20% of rated input BTU.

LIMIT CONTROLS

1. HIGH LIMIT

If boiler is equipped with a manual reset High Limit,

push the reset button and set the Limit(s) to 30° - 40°F

above operating temperature.

2. FLOW SWITCH

Dual purpose control shuts off boiler in case of

pump failure or low water condition.

3. 100% PILOT SAFETY

All standard boilers above 400,000 BTUH input are

equipped with pilot safety(ies), which close the main

valve within 8/10 of a second whenever the pilot flame

is interrupted. Pilot flame is automatically lit when the

device is powered. Unit performs its own safety check

and opens the main valve only after the pilot is proven

to be lit.

4. LOW WATER CUTOFF

The low water cut off automatically shuts down

burner whenever water level drops below probe. 90

second time delay prevents premature lockout due to

temporary conditions such as power failure or air pock-

ets.

5. HIGH AND LOW GAS PRESSURE SWITCHES

These switches sense either high or low gas pres-

sures and automatically shut down burners if abnormal

pressures exist.

6. BLOCKED VENT SHUT-OFF SYSTEM

All indoor boilers below 300,000 BTUH input em-

ploy a blocked vent shut-off system designed to shut off

main burner gas in the event the venting system is

totally blocked.

In the event the blocked vent shut-off system is

actuated, do not attempt to place the boiler in operation,

but contact a qualified service agency.

7. FLAME ROLL-OUT

SAFETY SHUT-OFF SYSTEM

All boilers below 300,000 BTUH input employ a

flame roll-out safety shut-off system designed to shut-

off the main burner gas in the event of sustained flame

roll-out.

In the event the flame roll-out safety system is

actuated, do not attempt to place the boiler in operation,

but contact a qualified service agency

2

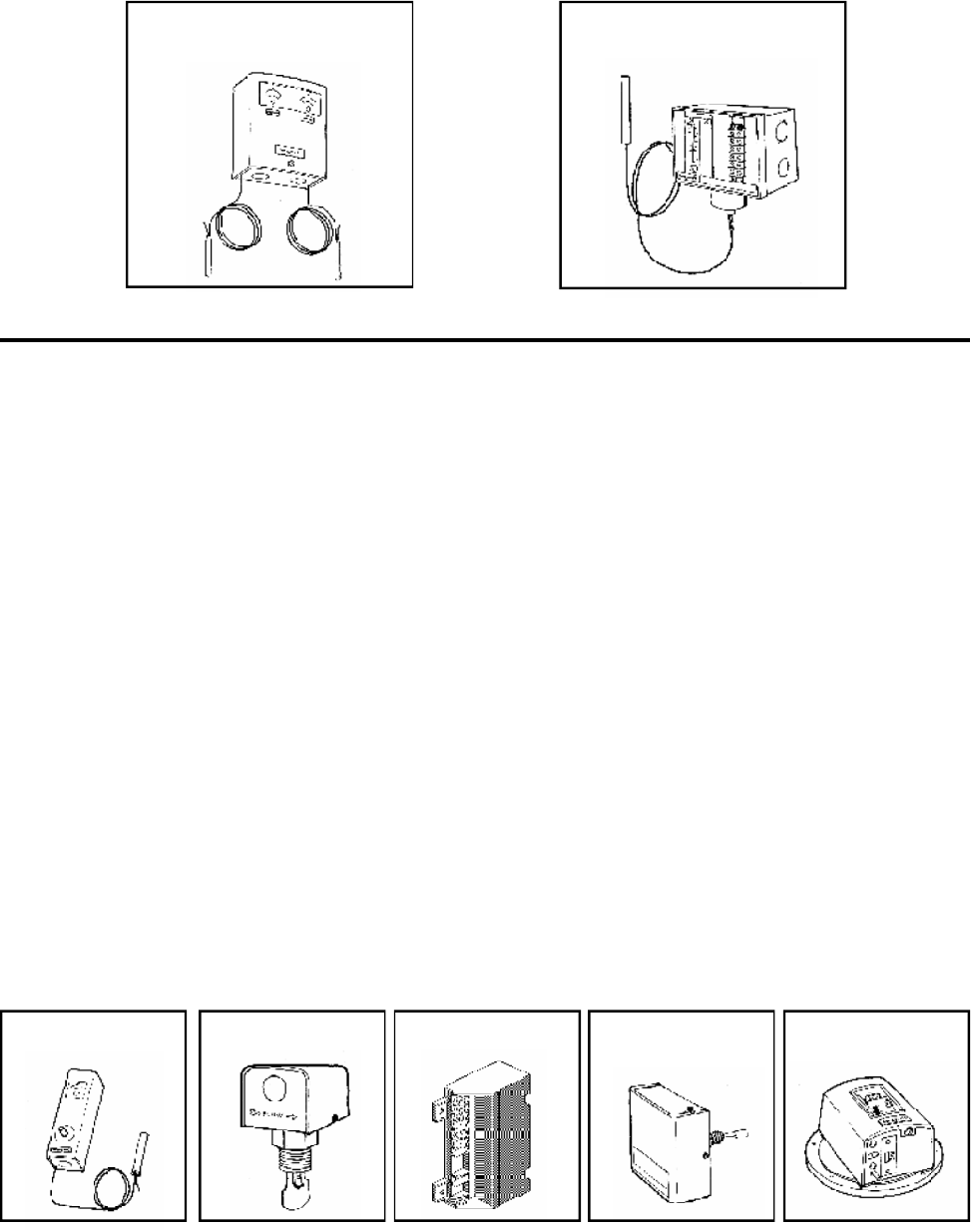

MANUAL RESET

HI LIMIT

FLOW SWITCH PILOT SAFETY LOW WATER

CUTOFF

HIGH OR LOW GAS

PRESSURE SWITCH

HIGH LIMIT AND

TEMP CONTROL

TEMP CONTROL

FOR MOTORIZED MODULATION

1 2

3

4 5

Fig # 9314 Fig # 9317 Fig # 8929 Fig # 9316 Fig # 9312