9. Install a coupling, nipple, union and sediment trap

onto the right-hand end of the main gas line and

then install the gas line, making sure that a manu-

al shut-off valve has been installed within 10 ft of

the heater.

10. Replace the left and right front panels on the

heater.

Gas Supply Pressure

A minimum of 5.0 in. WC and a maximum of 10.5 in.

WC upstream gas pressure is required under load and

no-load conditions for natural gas. A minimum of 11.0

in. WC and a maximum of 13.0 in. WC is required for

propane gas. The gas pressure regulator(s) supplied

on the heater is for low-pressure service. If upstream

pressure exceeds 14.0 in. WC, an intermediate gas

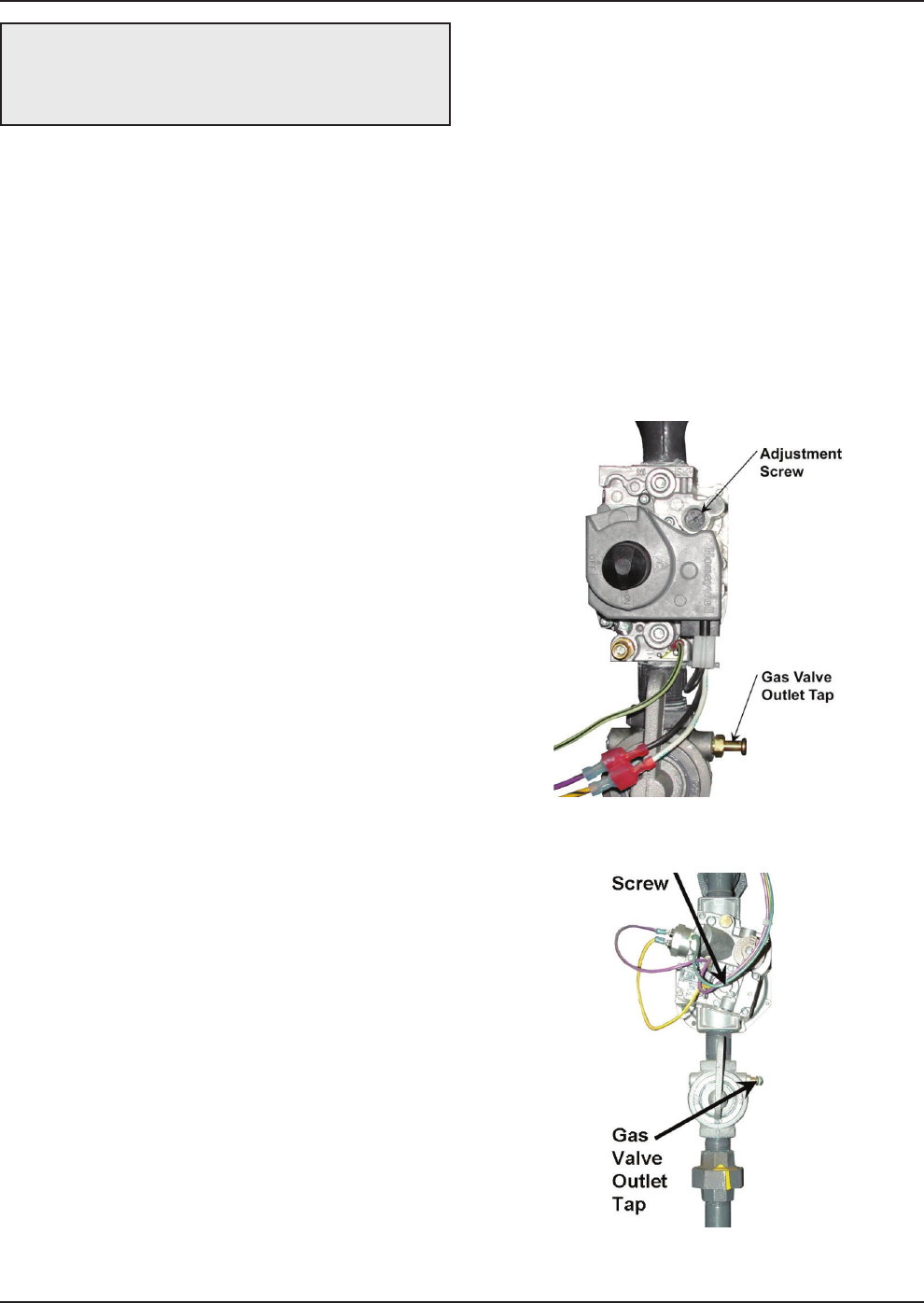

Fig. 15: Gas Valves

CAUTION: Support gas supply piping with

hangers, not by the heater or its accessories. Make

sure the gas piping is protected from physical

damage and freezing, where required.

Reversing Gas Supply Connection

Reversing the standard fuel connection from the left-

hand to the right-hand side is a simple field operation.

1. Disconnect all electrical power from the heater (if

applicable).

2. Disconnect the main gas pipe from the heater (if

applicable).

3. Remove the left and right front panels from the

heater.

4. Locate the main gas line that traverses across the

heater above the manifold risers.

5. Remove the pipe cap from the right-hand end of

the main gas line.

6. Reinstall the pipe cap on the left-hand end of the

main gas line.

7. Remove plastic cap from the right-hand side panel

and reinstall into the standard main gas opening

located on the left-hand side of the heater.

8. Remove the rubber grommet from the left-hand-

side panel and reinstall into the standard main gas

opening, located on the right-hand side of the

heater.

pressure regulator, of the lockup type, must be

installed.

When connecting additional gas utilization equipment

to the gas piping system, the existing piping must be

checked to determine if it has adequate capacity for

the combined load.

The gas valve pressure regulator(s) on the heater are

nominally preset at 3.5 in. WC for natural gas, and

10.5 in. WC for propane gas. The pressure at the gas

valve outlet tap, measured with a manometer, while in

operation should be 3.5 ± 0.1 in. WC for natural gas

and 10.5 in. ± 0.1 in. WC for propane gas. If an adjust-

ment is needed, remove the adjustment screw cover

and turn the adjustment screw clockwise to increase

pressure or counter-clockwise to lower pressure.

Models 399B–2339B

Models 989B–2339B

20

Adjustment