18

Potable Water and Space Heating

1. All piping materials and components connected to

the water heater for the space heating application

shall be suitable for use with potable water.

2. Toxic chemicals, such as used for boiler treatment,

shall not be introduced into the potable water used

for space heating.

3. If the heater will be used to supply potable water,

it shall not be connected to any heating system or

components previously used with a non-potable

water heating appliance.

4. When the system requires water for space heating

at temperatures higher than 140°F, a means such

as a mixing valve shall be installed to temper the

water in order to reduce scald hazard potential.

CAUTION: When this heater is used for both

potable water and space heating, observe the

following to ensure proper operation.

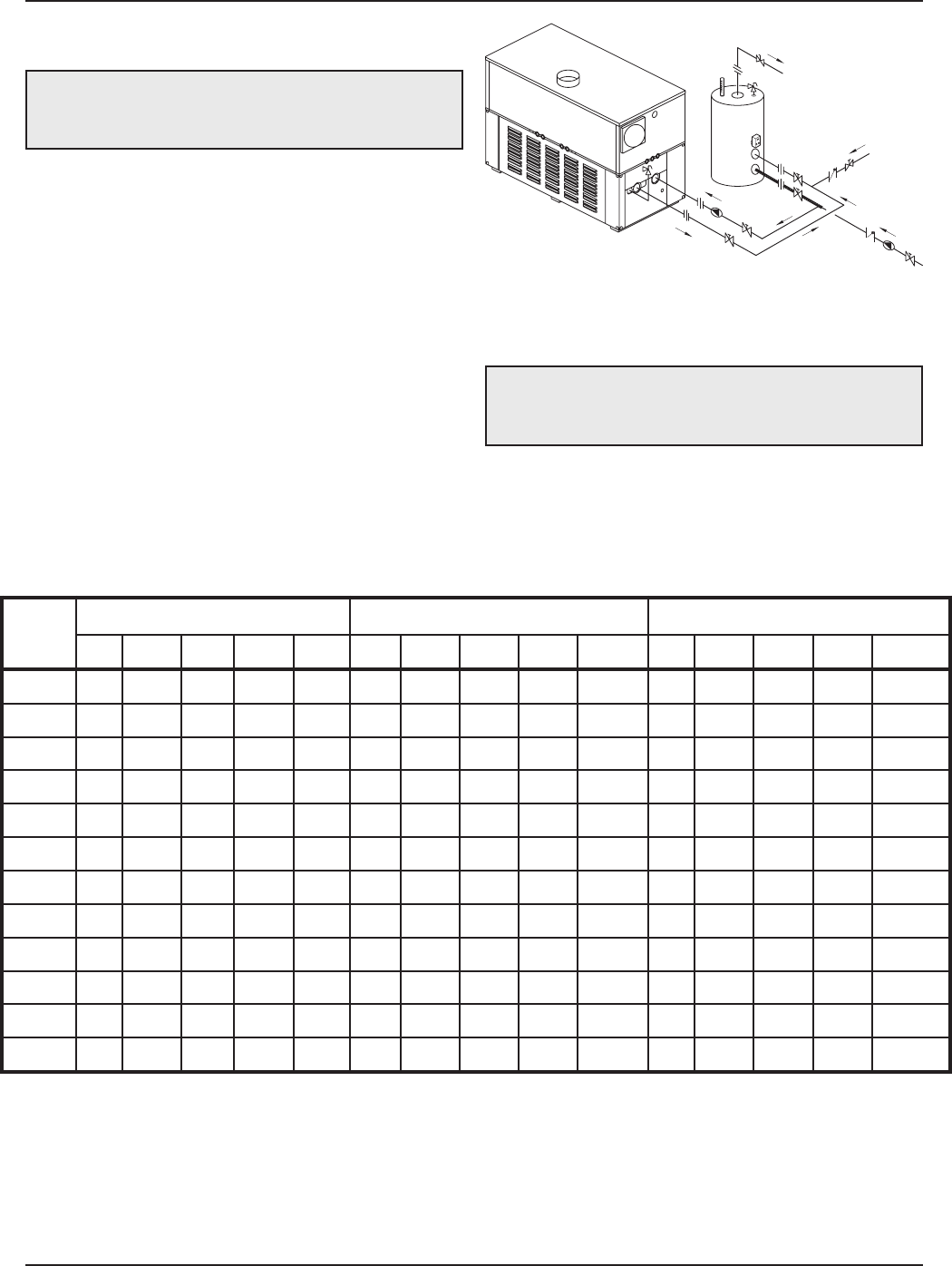

Fig. 13: Single Domestic Hot Water Heater and Storage

Tank

Table H: Domestic Water Heater Flow Rate Requirements

ΔT = Temperature rise, °F.

ΔP = Pressure drop through heat exchanger, ft.

SHL = System head loss, ft. (System head loss based on heater and tank placed no more than 5 ft apart and equivalent length pipe/fittings as fol-

lows: 2 in. tube = 25 ft; 2 1/2 in. tube = 80 ft.

gpm = Gallons per minute, flow rate.)

MTS = Minimum tubing size.

*Must utilize optional cupro-nickel tubes.

**With Hard Water (16-25 grains per gallon), the operating control must be set no higher than 130F for scale free operation. For operating temper-

atures above 130F, a water softener must be utilized.

Model

No.

Soft (0–4 grains per gallon) Medium (5–15 grains per gallon) Hard* (16–25** grains per gallon)

ΔT gpm ΔP MTS SHL ΔT gpm ΔP MTS SHL ΔT gpm ΔP MTS SHL

399B 17 40 2.0 2 4.4 13 52 3.4 2 7.2 8 90 10.0 2 20.5

499B 21 40 2.1 2 4.5 16 52 3.5 2 7.4 9 90 10.4 2 20.9

649B 28 40 2.2 2 4.6 20 55 4.1 2 8.4 12 90 10.8 2 21.3

749B 30 42 2.6 2 5.2 20 63 5.7 2 11.1 14 90 11.3 2 21.8

899B 30 51 3.9 2 7.6 20 76 8.4 2 16.1 17 90 11.7 2 22.2

989B 28 60 2.7 2 1/2 4.6 20 83 5.2 2 1/2 8.6 13 132 13.1 2 1/2 21.0

1259B 30 72 4.4 2 1/2 7.0 20 106 9.6 2 1/2 14.8 16 132 14.8 2 1/2 22.7

1529B 30 86 7.1 2 1/2 10.7 20 132 16.5 2 1/2 24.4 20 132 16.5 2 1/2 24.4

1799B 30 101 10.7 2 1/2 15.5 23 132 18.3 2 1/2 26.1 23 132 18.3 2 1/2 26.1

1999B 30 112 13.9 2 1/2 19.7 26 132 19.0 2 1/2 26.9 26 132 19.0 2 1/2 26.9

2069B 30 116 14.8 2 1/2 21.0 27 132 19.0 2 1/2 26.9 27 132 19.0 2 1/2 26.9

2339B 30 132 21.4 2 1/2 29.3 30 132 21.4 2 1/2 29.3 30 132 21.4 2 1/2 29.3

Gas Supply

Gas piping must have a sediment trap ahead of the

heater gas controls, and a manual shut-off valve lo-

cated outside the heater jacket. It is recommended

that a union be installed in the gas supply piping adja-

cent to the heater for servicing. A pounds-to-inches

DANGER: Make sure the gas on which the heater

will operate is the same type as specified on the

heater’s rating plate.