9

VENT DAMPER

NORMAL OPERATION SUMMARY

For safe, efficient operation, the vent damper and all flue product carrying areas of the appliance must

be checked annually, with particular attention given to deterioration from corrosion or other sources.

Check vent damper operation as follows:

1. When the boiler is off, check that the vent damper position indicator points to the closed position, below.

Fig. # 8181.0

FIG. 4- VENT DAMPER POSITION INDICATOR SHOWING OPEN & CLOSED POSITIONS.

2. Turn the thermostat or controller up to call for heat and check that the vent damper indicator points to the

open position, below.

3. Turn the thermostat or controller down again and check that the vent damper position indicator returns to

the closed position.

THE VENT DAMPER MUST BE INSPECTED AT LEAST ONCE A YEAR BY A TRAINED, EXPERIENCED

SERVICE TECHNICIAN. THE NAME OF THE PERSON WHO ORIGINALLY INSTALLED YOUR VENT

DAMPER IS SHOWN ON THE INSTALLATION LABEL. DAMPER MUST BE IN OPEN POSITION WHEN

BOILER MAIN BURNERS ARE OPERATING.

FLAIR DAMPER

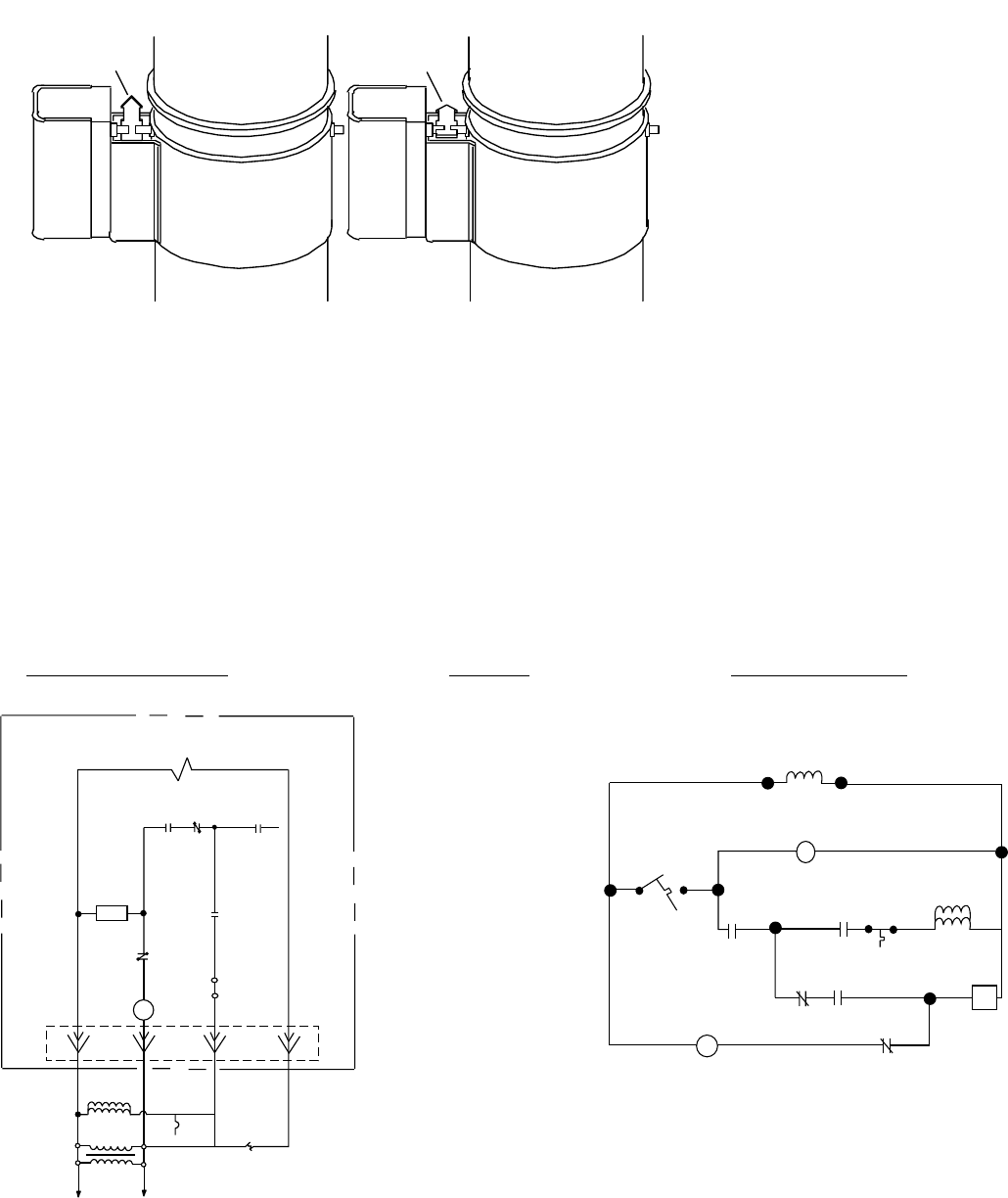

SYSTEM SCHEMATIC LEGEND LADDER DIAGRAM

M - Damper motor

R - Relay

ES - End Switch

SS1 - N/C Safety switch

SS2 - N/O Safety switch

contacts

TR - Transformer 120/24V

HL - High limit

GV - 24V gas Valve*

TH - Thermostat, heating,

low voltage

J - Jumper

* Note: Circuit shown with

damper in closed

position, no call

for heat.

Fig. #9002 Fig. #9003

NOTE: To place vent damper in

the open position to allow burner

operation do the following:

Turn the power off, turn the damper

blade to fully open position (arrow

facing same direction as vent

pipe). Turn power on.

DAMPER

POSITION

INDICATOR

DAMPER

POSITION

INDICATOR

DAMPER OPEN DAMPER CLOSED

SS

R

2

SS

2

ES

R

SC

R

1

M

2

3

41

JUMPER

GV

24 VAC

TR

HL

L

L

12

120 VAC

60Hz

TH

1

R

2

4

3

J

SS

HL

GV

1

ES

R

2

SC

M

24 V AC

R

1

SS

2

TH