35

INSTRUCTIONS PERTAINING TO THE INSTALLER 926.772.1 - GB/IE

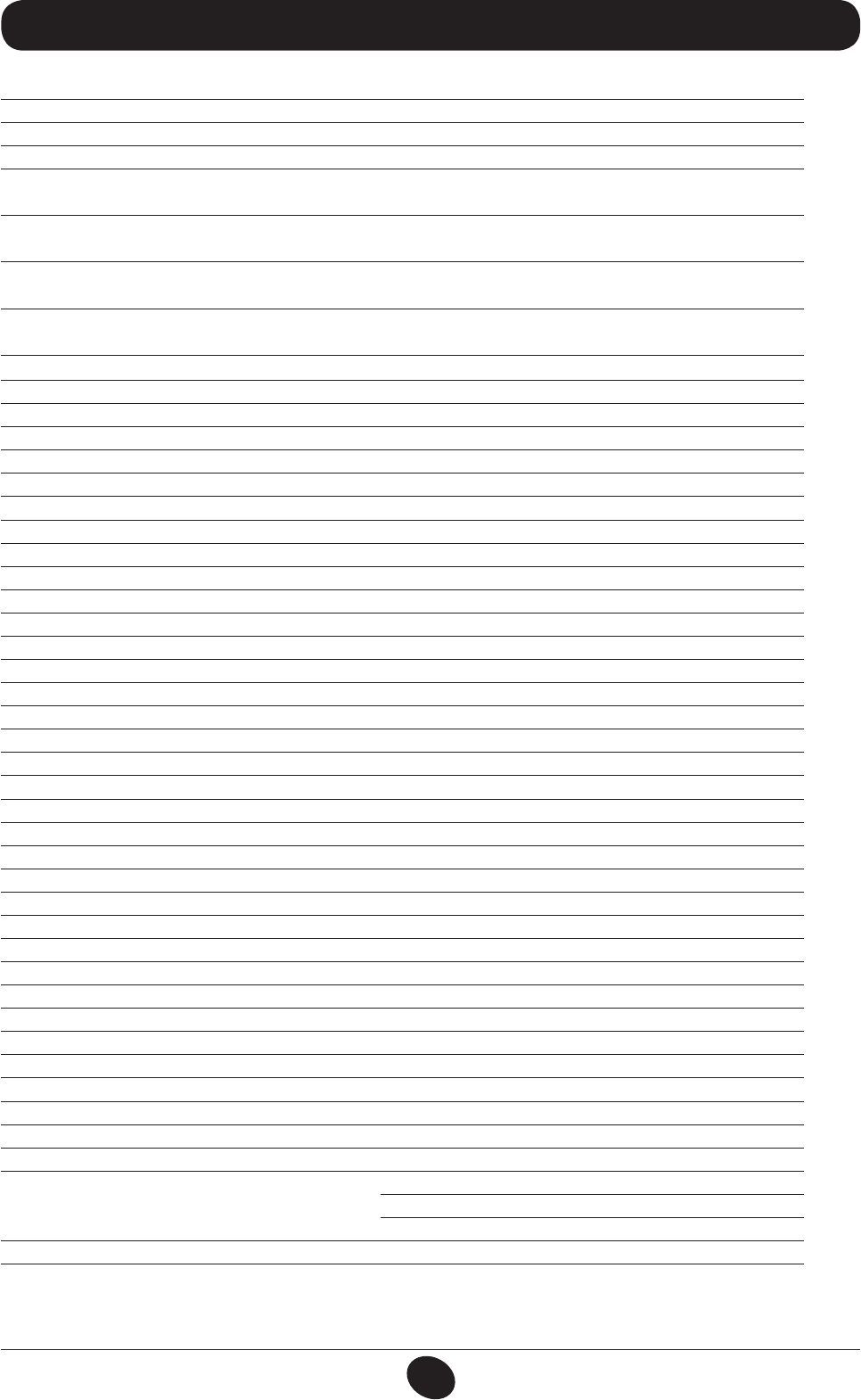

24. TECHNICAL DATA

Boiler model WH WH 46 WH 65

Category II2H3P II2H3P

Nominal heat input (net/gross) kW 46,4 - 51,5 67,0 - 74,4

Reduced heat input (net/gross) kW 15 - 16,6 20,0 - 22,2

Rated heat output 75/60°C

kW 45,0 65,0

kcal/h 38.700 55.900

Rated heat output 50/30°C

kW 48,7 70,3

kcal/h 41.880 60.460

Reduced heat output 75/60°C

kW 14,5 19,3

kcal/h 12.470 15.820

Reduced heat output 50/30°C

kW 15,8 21,0

kcal/h 13.588 18.060

Useful efciency according to 92/42/CEE directive —

★★★★ ★★★★

Useful efciency max heat output 75/60 °C net/gross % 97,3 / 87,3 97,4 / 87,4

Useful efciency max heat output 50/30 °C net/gross % 105,1 / 94,5 105,2 / 94,5

Useful efciency 30% heat output % 107,6 107,6

Central heating system max. pressure bar 4 4

Heating circuit temperature range °C 25÷80 25÷80

Type — C13 - C33 - C43 - C53 - C63 - C83 - B23

Concentric ue duct diameter mm 80 80

Concentric air duct diameter mm 125 125

Twin-pipe ue duct diameter mm 80 80

Twin-pipe air duct diameter mm 80 80

Max. ue mass ow rate kg/s 0,022 0,032

Min. ue mass ow rate kg/s 0,007 0,010

Max. ue temperature °C 74 75

NOx class — 5 5

NOx mg/kWh 38,4 37,7

Type of gas used — G20/G31 G20/G31

Natural gas pressure 2H mbar 20 20

Propane gas pressure 3P mbar 37 37

Gas Consumption (NG) m

3

/hr 4,91 7,08

Gas Consumption (LPG) m

3

/hr 1,89 2,74

Minimum Operating Pressure Bar 1 1

High Level Ventilation to BS6644 boiler room cm

2

92,8 134

Low Level Ventilation to BS6644 boiler room cm

2

185,6 268

Water Flow at 20°C ∆t lit/sec 0,54 0,78

Hydraulic Resistance at 20°C ∆t kPa 11,7 20,6

Cold Feed Size to BS6644 mm 19 25

Safety valve size to BS6644 (open vent system) mm 19 19

Water Content lit 5,1 6,5

Maximum Flow Temperature °C 85 85

Ventilation to BS5440 cm

2

Power supply voltage V 230 230

Power supply frequency Hz 50 50

Rated power supply W 75 125

Net weight kg 64 72

Dimensions height mm 950 950

width mm 600 600

depth mm 466 466

Protection-limit against humidity and water leakages (**) IPX5D IPX5D

(**) according to EN 60529