48

© Baxi Heating UK Ltd 2008

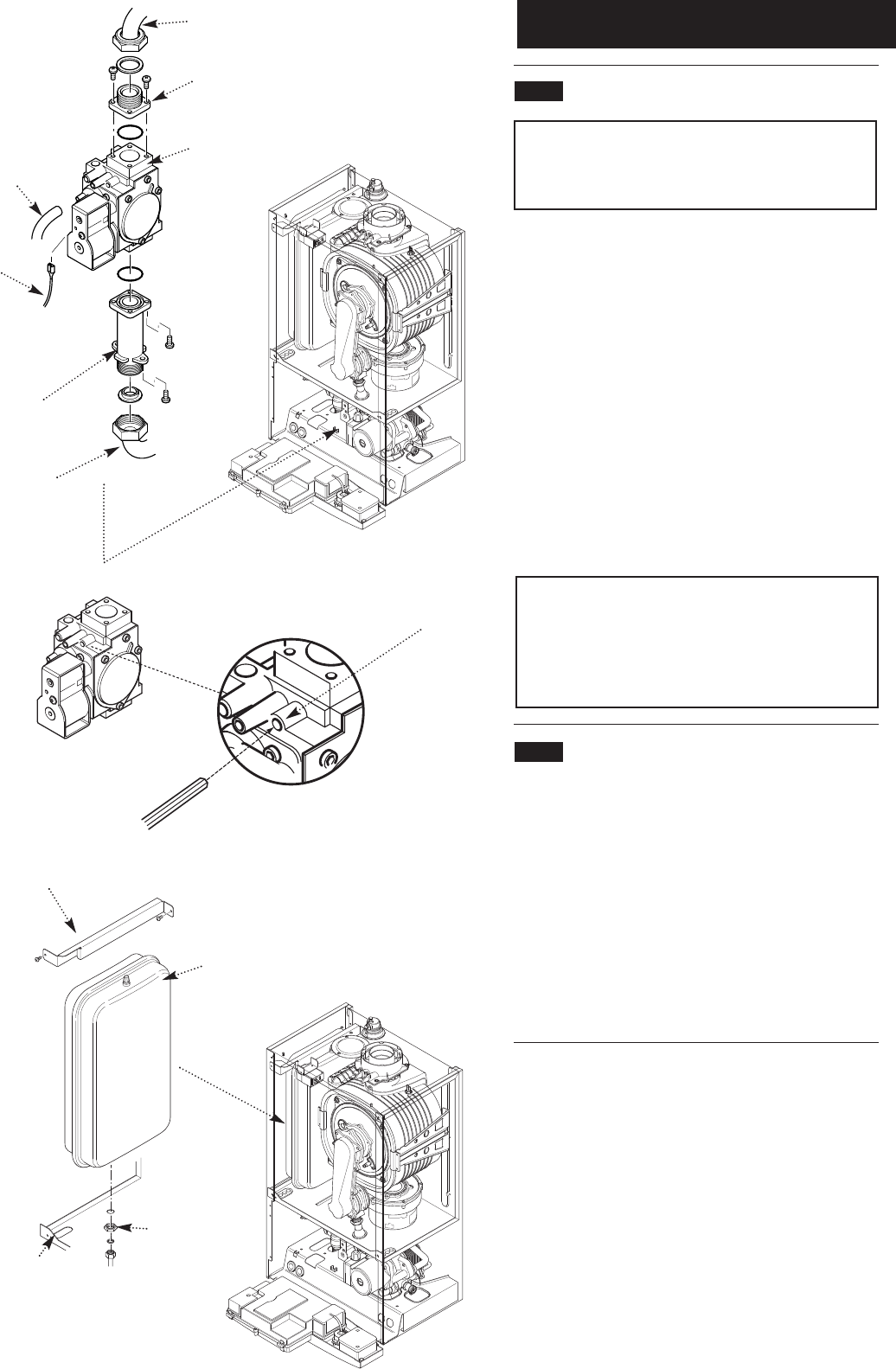

Gas Valve

Valve

Inlet Pipe

Gas Feed

Elbow

Fig. 103

Ignition Lead

Expansion Vessel

Boiler Chassis

Lock Nut

Fig. 104

Retaining Bracket

Sensing Pipe

Venturi Inlet

Pipe

Outlet Adaptor

14.0 Changing Components

14.23

Gas Valve (Fig. 103)

IMPORTANT: After replacing the valve the CO

2

must be

checked and adjusted as detailed in Section 15.0

Combustion Check. Only change the valve if a suitable

calibrated combustion analyser is available.

1. Turn the gas cock off and undo the nut on the gas feed

elbow under the boiler.

2. Remove the screws securing the inlet pipe flange to the

boiler bottom panel.

3. Pull off the earth lead and sensing pipe.

4. Undo the nut on the venturi inlet pipe and slacken the nut

on the venturi. Ease the pipe aside and remove the gas valve.

5. Remove the outlet adaptor and inlet pipe and transfer them

to the new valve. Examine the ‘O’ ring seals, replace if

necessary.

6. Reassemble in reverse order.

NOTE: To assist the boiler to light prior to final setting,

use a suitable hexagon key to wind out the Gas/Air

adjustment screw until it is flush with the valve body, then

turn the screw 4 full turns clockwise (Fig. 103a). If the

boiler will not light, or the correct CO

2

cannot be achieved

contact the ‘heateam’ technical helpline.

14.24 Expansion Vessel (Fig. 104)

1. Drain the primary circuit and undo the nut on the vessel

connection pipe.

2. Undo and remove the locknut securing the vessel spigot to

the boiler air box.

3. Remove the bracket and vessel from the boiler.

4. Locate the retaining bracket on the upper flange of the

vessel and fit to the boiler.

5. Reassemble in reverse order.

Fig. 103a

Gas/Air

Adjustment Screw