29

10.0 Installation

© Baxi Heating UK Ltd 2008

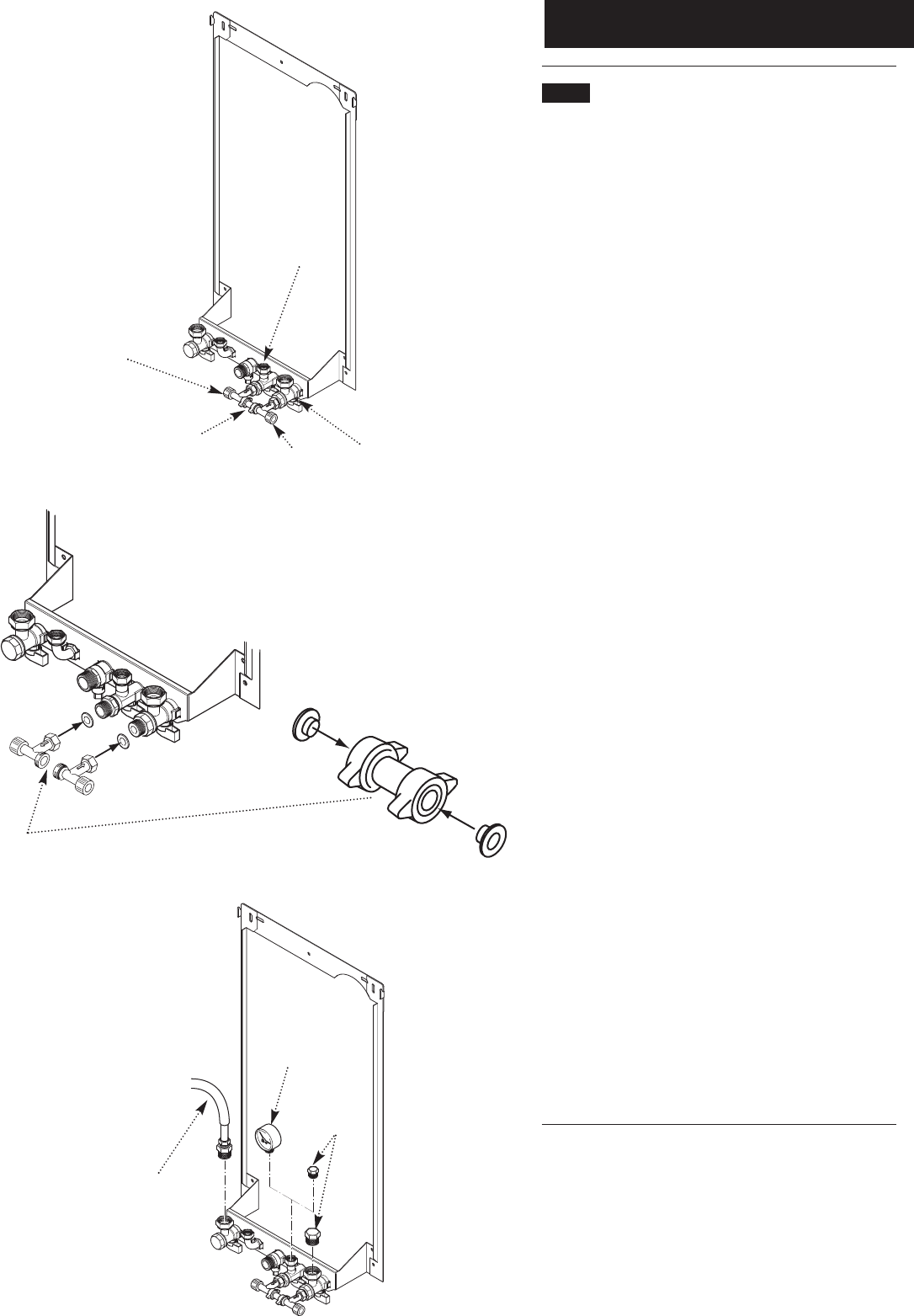

10.3 Fitting the Filling Loop

1. The filling loop supplied with the boiler can be

connected to the taps on the wall plate at this point.

2. The filling loop is to be connected between the mains

cold water inlet and central heating return isolation taps.

3. The loop and valves must be connected as shown in

the diagram (Fig. 44a).

4. Note the orientation of the flow direction arrows on

the stop valve and double check/stop valves.

5. Remove the end caps from the isolation taps and put

to one side. Connect the valves to the taps. Ensure that

the fibre washers supplied are used on these joints.

6. Connect the temporary loop, ensuring that the seals

are fitted.

To fill, test and flush if required (Fig. 44c)

7. Take the blanking plugs from the kit, and using washers

supplied with the boiler, connect them to the central

heating flow and return taps, and the cold inlet tap. The

system can now be filled by opening the cold inlet supply

and stop valves.

8. If desired a suitable gauge can be connected to one of

the taps so that the system may be accurately

pressurised.

9. All joints, fittings and system components can now be

examined for soundness at operating pressure.

10. The system can be flushed by turning off the central

heating tap and connecting a suitable fitting to the loose

nut. From the fitting a hose pipe can be run to the

nearest convenient drain. When the tap is reopened the

system will flush.

11. Remove the blanking plug(s), pressure gauge and

flushing equipment from the appliance if used.

12. Continue with the installation and commissioning.

13. The filling loop must be disconnected and completely

removed after the system is pressurised.

14. Hand tighten the two previously removed end caps

to the stop valve and double check valve.

Fig. 44a

Fig. 44c

CH Return

Cold Inlet

Double Check Valve

& Stop Valve

Stop Valve

Temporary Filling

Loop

Fitting the Valves

to the Taps

Temporary Loop and

Flanged Washers

Blanking

Plugs

Pressure

Gauge

Hose and

Fitting

Fig. 44b