38

© Baxi Heating UK Ltd 2008

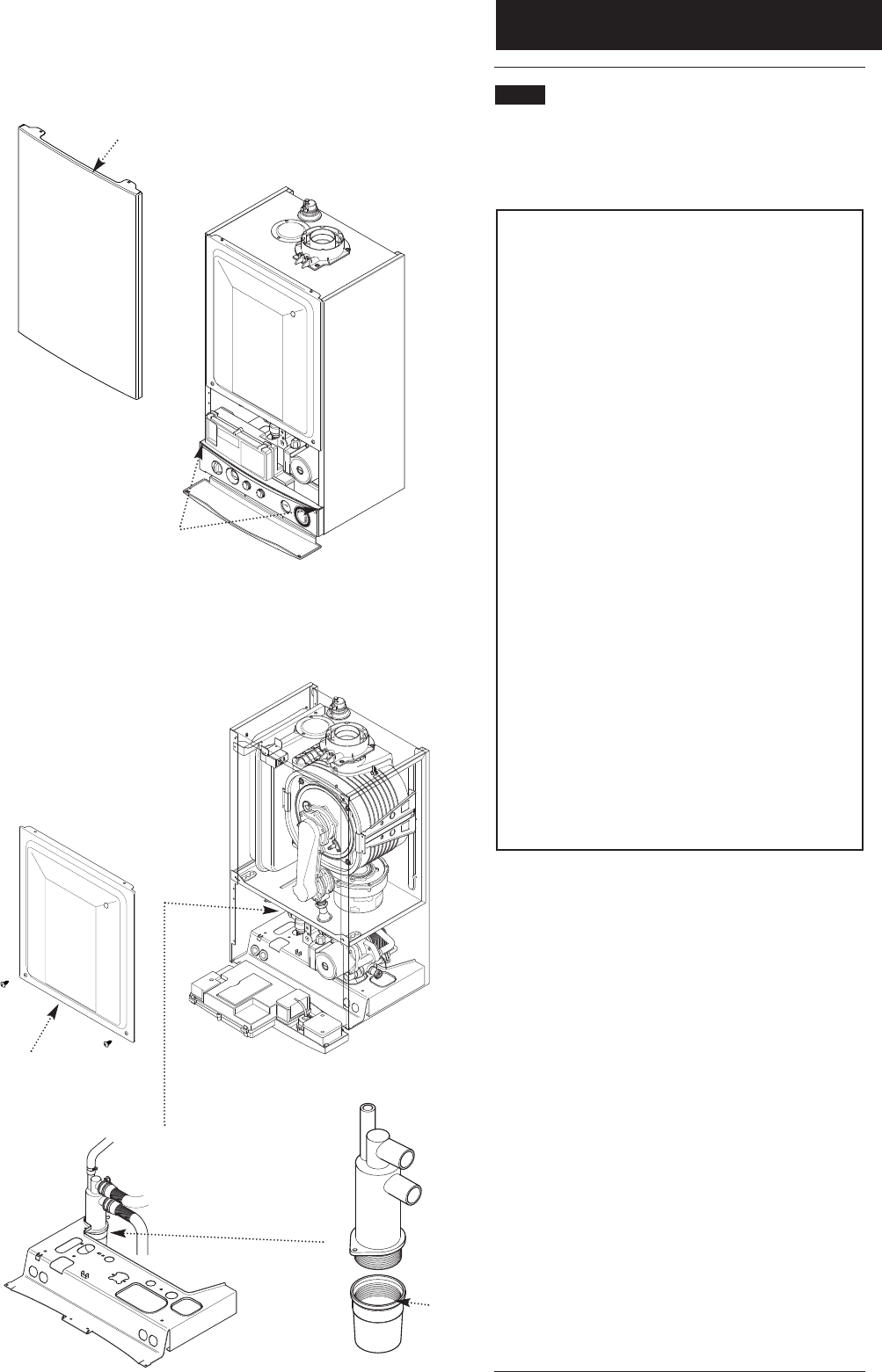

Case Front Panel

Fig. 73

Facia Panel Securing

Screws

Fig. 74

Inner Door

Panel

Fig. 75

Sump

13.0 Servicing

13 .1 Annual Servicing

1. For reasons of safety and economy, it is recommended that

the boiler is serviced annually. Servicing must be performed by

a competent person in accordance with B.S. 7967-4:2007.

If a suitably calibrated combustion analyser is available it

may not be necessary to perform a full strip down of the

appliance. Proceed as follows.

Check for/inspect:-

Evidence of leakage of products of combustion

Water leaks

Heat stress

Deterioration such as corrosion

Visible condition of seals and joints

Flue system and ventilation

Condensate drain system

Operation at designed maximum heat input

If the above are satisfactory perform a combustion check

The CO/CO

2

ratio must be less than 0.004 and the CO

2

should be 8.7% ± 0.2 (max. rate) and 8.4% ± 0.2 (min.

rate). This can be adjusted - see Section 15.0 - if the

readings are incorrect. When correct combustion

readings cannot be achieved by adjustment a full strip

down must be performed - see below. Carefully check

items such as the burner, injector and heat exchanger

for blockage or damage, rectifying as necessary. Re-

check the combustion. Once satisfactory readings have

been achieved and any other defects corrected complete

the relevant Service Interval Record section of the

Benchmark Commissioning Checklist at the rear of this

publication.

Where no suitable analyser is available a strip down

service must be performed as described below.

2. After servicing, complete the relevant Service Interval

Record section of the Benchmark Commissioning Checklist at

the rear of this publication.

If a full strip-down is to be performed proceed as follows:-

3. Ensure that the boiler is cool.

4. Ensure that both the gas and electrical supplies to the

boiler are isolated.

5. Slacken the screws securing the facia panel. Lift the

outercase panel so that its securing tabs are clear of the facia.

Remove the panel, allowing the facia to hinge down (Fig. 73).

6. Remove the screws securing the inner door panel. Lift the

panel slightly to disengage it from the studs on top of the case

(Fig. 74).

7. Unscrew the sump from the bottom of the condensate trap

assembly (Fig. 75).

8. Remove any deposits from the sump and trap. Clean as

necessary and replace the sump.