8 - 7

Mounting and commissioning the machine

8.03 Commissioning the machine

● Before commissioning the machine, check the electrical leads and pneumatic hoses for

any damage.

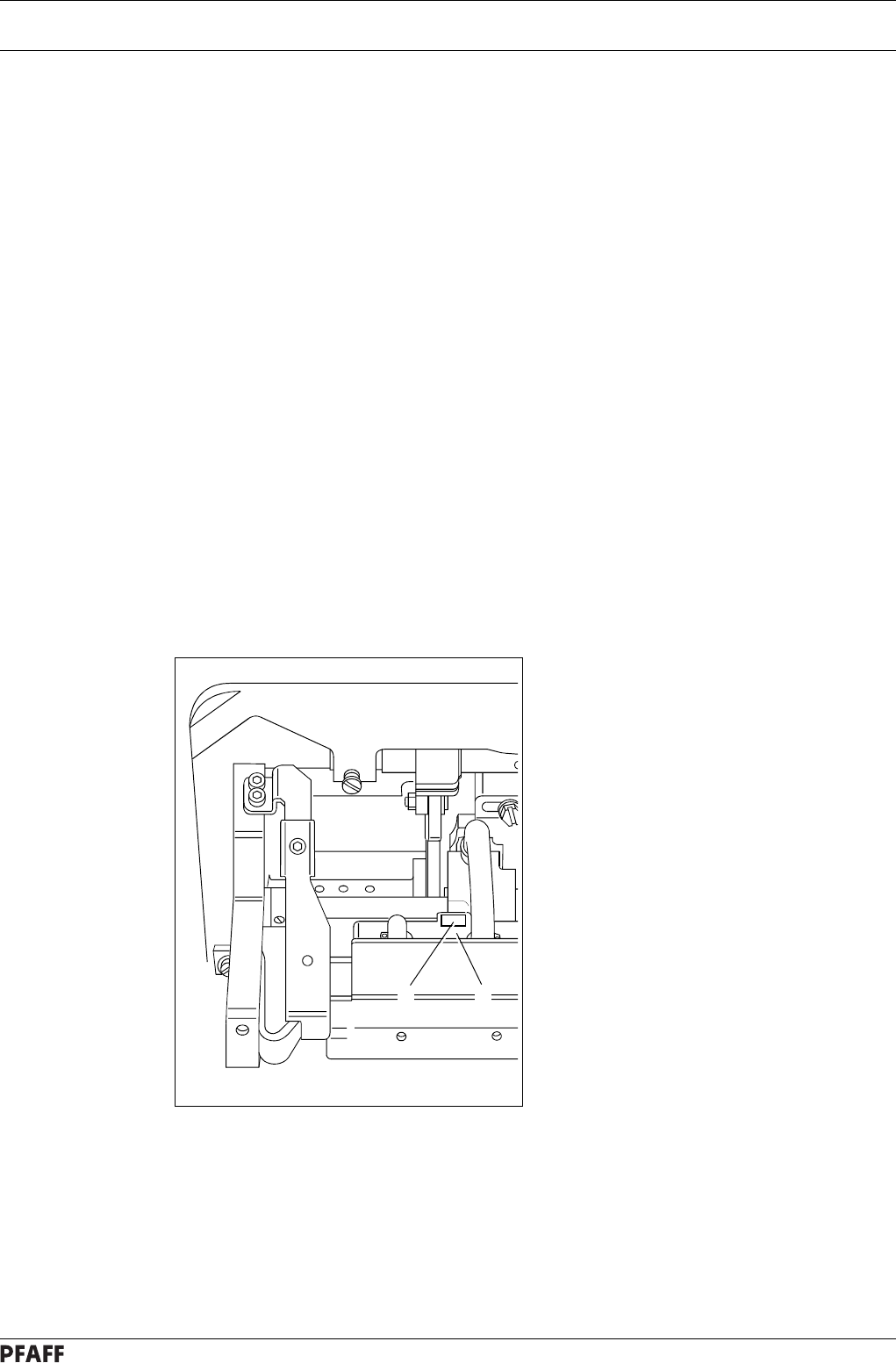

● Remove pin 1 of the oil reservoir 2 (Fig. 8 - 06). The pin serves only to protect the machine

from damage during transport and must not be used when sewing.

● Clean the machine thoroughly and oil it (see chapter 10 Care and maintenance)

● Have specialists ensure that the machine’s motor can be operated with the available

electricity supply and that it is connected correctly to the terminal box. If not, the machine

must not be operated.

● The handwheel must rotate towards the operator when the machine is running, if not, have

the motor re-adjusted converted by a specialist.

● Connect the machine to the compressed air system. The pressure gauge must display a

pressure of approx. 6 bar. If not, adjust the pressure to this value (see chapter 10.07

Checking the air pressure).

Fig. 8 - 06

1

2

8.04 Switching the machine on/off

● Switch on the machine (see chapter 7.01).

● Carry out a test run.