P/N 472089 Rev. E 4-19-05

14

INDOOR VENTING — General Requirements

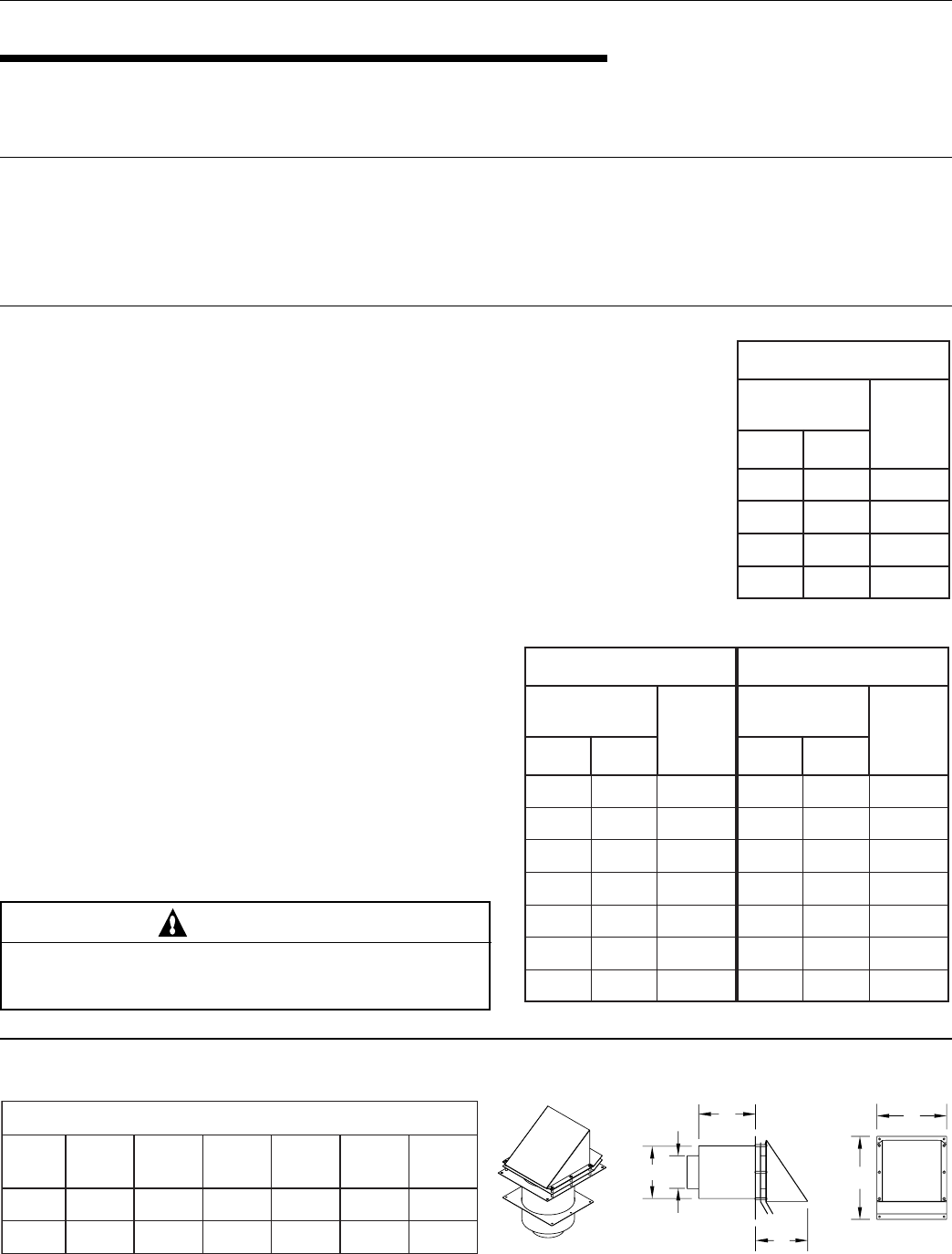

The vent pipe must be the same size or larger. The MiniMax NT LN heaters are capable of a 360-degree discharge

rotation and operate with a positive vent static pressure and with a vent gas temperature less than 400° F. The total length

of the horizontal run must not exceed the length that is listed below in the tables.

NOTE

The allowable vent runs for each vent pipe diameter are different and can not be exceeded.

Each 90-degree elbow reduces the maximum horizontal vent run by 8 feet and each 45-degree elbow in

the vent run reduces the maximum vent run by 4 feet. See the tables below for the maximum vent

lengths using 90-degree and 45-degree elbows.

The MiniMax NT LN is a “Category III” appliance and is an induced-draft pool and spa

heater which uses positive pressure to push flue gases through the vent pipe to the outside.

This requires a completely sealed vent system—single wall vent pipe with sealed-seams

and joints. Flue gases under positive pressure may escape into the dwelling with any

cracks or loose joints in the vent pipe, or improper vent installation. The vent pipe must

be of a sealed-seam construction, such as those listed for use with “Category III Appliances”,

and for operating temperatures less than 400° F. The use of listed thimbles, roof jacks and/

or side vent terminals are required; and the proper clearances to combustible materials

must be maintained in accordance with type of vent pipe employed—in the absence of a

clearance recommendation by the vent pipe manufacturer, the requirements of the Uniform

Mechanical Code should be met. The ventilation air requirements for the MiniMax NT

heater can be found on page 16. It is recommended that vent

runs over 18 feet be insulated to reduce condensation related

problems and/or the use of a condensate trap in the vent run

close to the heater may be necessary in certain installations

such as cold climates. The MiniMax NT LN heater is suitable

for through-the-wall venting, see table and dimensions below.

Recommended sources for Side-wall vent hood terminals

include: The Field Controls Co. (2308 Airport Road, Kingston,

NC 28501, (800)742-8368) and Tjernlund Products Inc. (1601

Ninth Street, White Bear Lake, MN 55110, (800) 255-4208)—

consult manufacturer for model information and availability.

CAUTION

Do NOT combine exhaust vent pipes to a common exhaust

vent in multiple unit installations. Run separate vent pipes.

epiPtneVhcni4

forebmuN

swoblE

mumixaM

nuRtneV

)teeF(

°09°54

1— 22

11 81

12 41

2— 41

epiPtneVhcni5epiPtneVhcni5

forebmuN

swoblE

mumixaM

nuRtneV

)teeF(

forebmuN

swoblE

mumixaM

nuRtneV

)teeF(

°09°54°09°54

02 542292

1— 542352

11 1424 12

12 733—92

13 333152

2— 733212

21 334—12

SRETAEHROFSTIKTNEVLLAWHGUORHT

traP

rebmuN

A.miDB.miDC.miDD.miDE.miDF.miD

235174.aiD.ni4.aiD.ni6.ni½8.ni61/56.ni8/521.ni8/501

345174.aiD.ni5.aiD.ni8.ni½8.ni8.ni8/521.ni8/501

Section III. Installation

Table 6.

Table 7.

Table 8.

Figure 5.

B

A

C

D

E

F