7

D. WATER BOILER PIPING

1. Refer to the Water Installation Survey and Hydronics

Institute Residential Hydronic Heating

Installation/Design Guide for Guidance.

2. The supply and return connections should be sized

to suit the system.

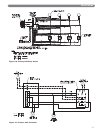

3. Pipe the supply and return in one of two ways as

shown in Figure 3.3:

a. Pipe the supply from the top of the rear section

and return to the bottom of the front section. Use

the 3/4" tapping in the top of the back section for

air elimination.

b. As an alternative, pipe the supply from the top of

the front section and return to the bottom of the

rear section. Provide air elimination means

within the supply piping.

4. When the return temperature from the system will be

below 150°F on oil boilers for extended periods

(heat pump systems, outdoor reset, snow melt, etc.),

provide piping and controls to protect the boiler from

condensation. Condensation will damage the boiler

and will lead to shortened boiler life and

maintenance problems.

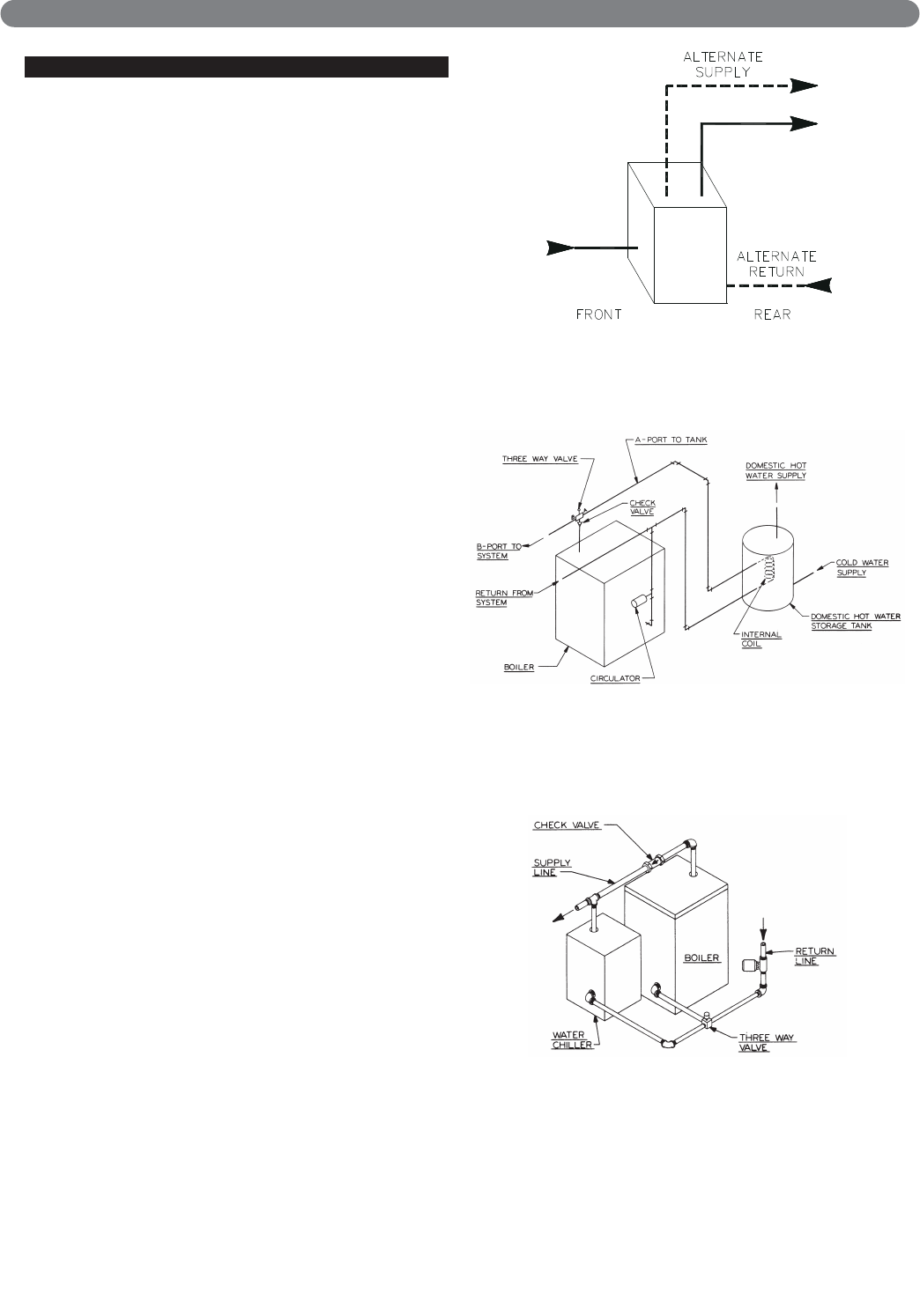

5. If using a Partner indirect fired water heater or other,

see Figure 3.4 for typical piping. Also refer to

additional instructions supplied with the Partner.

6. If the boiler is to be used in conjunction with a

refrigeration system, the chilled medium shall be

piped in parallel with boiler and proper valves

applied to prevent the chilled medium from entering

the boiler. Refer to Figure 3.5.

7. If the boiler is connected to heating coils located in

air handling units, the boiler piping system must be

equipped with flow control valves or other automatic

devices to prevent gravity circulation of the boiler

water during the cooling cycle.

PIPING AND CONTROLS

Figure 3.3: Water Boiler Piping

Figure 3.4: Piping with Peerless Indirect

Water Tank

Figure 3.5: Isolating Boiler from Chilled Medium

on Chiller Systems