9

F. CONTROLS

1. Water Boiler Controls:

Install the limit / operating control, pressure-

temperature gauge and safety relief valve. See Figure

7.1 (Section 7) for proper location. For installations

subject to UL726, a second operating control that

senses water temperature is also required (not

provided). Use an L4080B or equivalent. Install in

the supply piping near the boiler.

2. Steam Boiler with Float Low Water Cut-Off:

Install pressure limit control, pressure gauge, gauge glass

trim and safety valve. See Figure 3.8, Figure 3.9, and

Figure 7.1 (Section 7). See also control manufacturer's

instruction sheet shipped with the control.

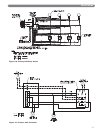

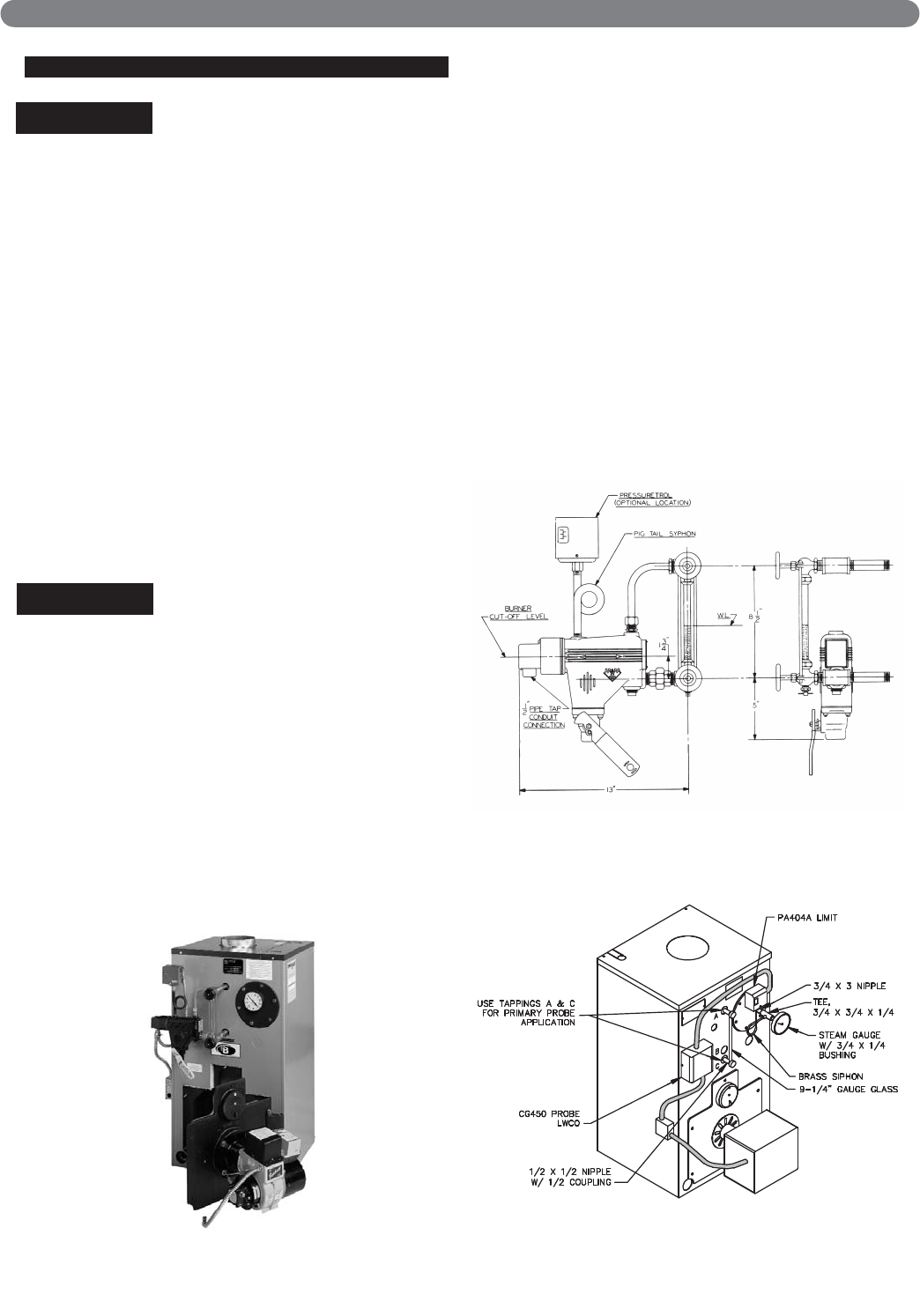

3. Steam boilers with Probe Low Water Cut-Off:

Probe models use a longer gauge glass than float

models. The following components are packed in the

Probe Carton (90759):

·

Hydrolevel CG450 LWCO

·

Gauge glass 22-162-10

·

3/4"x 3" nipple

·

3/4" x 3/4" x 1/4" tee

·

(2) 1/2" couplings

Use these components along with the gauge glass

handles and other components from the Steam Trim

Carton and install fittings and controls per Figure 3.10.

The shorter gauge glass located in the Steam Trim

Carton is not necessary for the probe application.

4. Steam boilers subject to UL726:

For installations subject to UL726, a second

operating control that senses steam pressure is

required (not provided). Use a PA404A or

equivalent. On probe boilers, install the additional

pressure control opposite the standard PA404A using

a cross instead of a tee along with a second brass

siphon (not provided). On float boilers, install the

additional pressure control in the location normally

used for the standard PA404A on steam-probe

boilers (fittings not provided).

5. For complete information on servicing and

adjustment of controls, refer to the attached control

specification sheets.

Pipe the discharge of the safety

valve or relief valve to prevent injury

in the event of pressure relief. Pipe

the discharge to a drain. Provide

piping that is the same size as the

relief valve.

CAUTION

Use only the Hydrolevel CG450 as

a primary probe low water. The

CG450 includes a cycle timer to

sense water level under foaming or

surging conditions. Failure to use

this model could result in a failed

heat exchanger.

CAUTION

PIPING AND CONTROLS

Figure 3.8: Steam Boiler with Float Low

Water Cut-Off

Figure 3.9: Assembling Float Low Water Cut-Off

Figure 3.10: Steam Boiler with Probe Low

Water Cut-Off