MACH® Series

Gas-Fired Boiler Installation

Page 27

MACH C750, C900 & C450

Required Tools:

TORX® T40 or 5 mm hex wrench

3 mm or 7/64 in hex wrench

Combustion analyzer

The MACH C750,C900 and C1050 boilers are

equipped with a Honeywell combined gas/air control

and gas safety shut off control valves. The valve

functions in parallel with the variable speed

combustion blower to supply the correct gas air ratio

for optimum performance and efficiency. The

combustion blower speed is controlled automatically

and determines the amount of negative pressure felt at

the gas safety shut off / control valves. The gas/air

regulator adjusts gas flow to maintain the proper

pressure at the outlet nozzle of the associated valve.

Adjustment:

There must be sufficient load to operate the boiler at

high fire to perform the following adjustments. Start

the boiler and observe proper operating parameters for

the system.

High Fire Setting

Set boiler to the “Test Mode High”, as described

above, to achieve maximum firing rate of the boiler.

Check combustion readings using a combustion

analyzer. If combustion readings are not in

accordance with Table 3-1, adjust as follows:

Remove the flat, round, blue plastic cap from the

cover. Using a 3mm (7/64”) hex wrench, turn the

adjustment screw counterclockwise to increase or

clockwise to decrease gas flow and achieve the desired

CO

2

or O

2

level; see Table 3-1 for correct settings.

(There will be a slight time delay between the

adjustment and the response of the CO

2

/O

2

measuring

instrument. Adjust the settings in small increments and

allow the combustion readings to stabilize before

readjusting. When desired adjustments are complete,

reinstall the blue plastic cap on the cover.

Low Fire Setting

Set boiler to the “Test Mode Low”, as described

above, to achieve minimum firing rate of the boiler.

Check combustion readings using a combustion

analyzer. If combustion readings are not in

accordance with Table 3-1, adjust as follows:

Remove the cap on the gas regulator using a slotted

screwdriver (See Fig. XX). This will expose the offset

adjustment screw.

Using a TORX® T40 or a 5 mm hex wrench, carefully

adjust the low fire gas setting to achieve the CO

2

/O

2

level prescribed in Table 3-1.

Note: The rotation of the Low Fire adjustment is

opposite of the High Fire as follows: Clockwise

rotation increases gas flow, counterclockwise rotation

decreases gas flow.

Adjustments to the offset pressure regulators should

not exceed ¼ turn at a time before allowing the

readings to respond and stabilize.

After proper low fire offset adjustment is made,

reinstall the slotted cap on the regulator.

Following all gas valve adjustments, check for proper

light-off and verify correct fuel/air mix and

combustion quality throughout the entire firing range

(from lowest to highest fan speed).

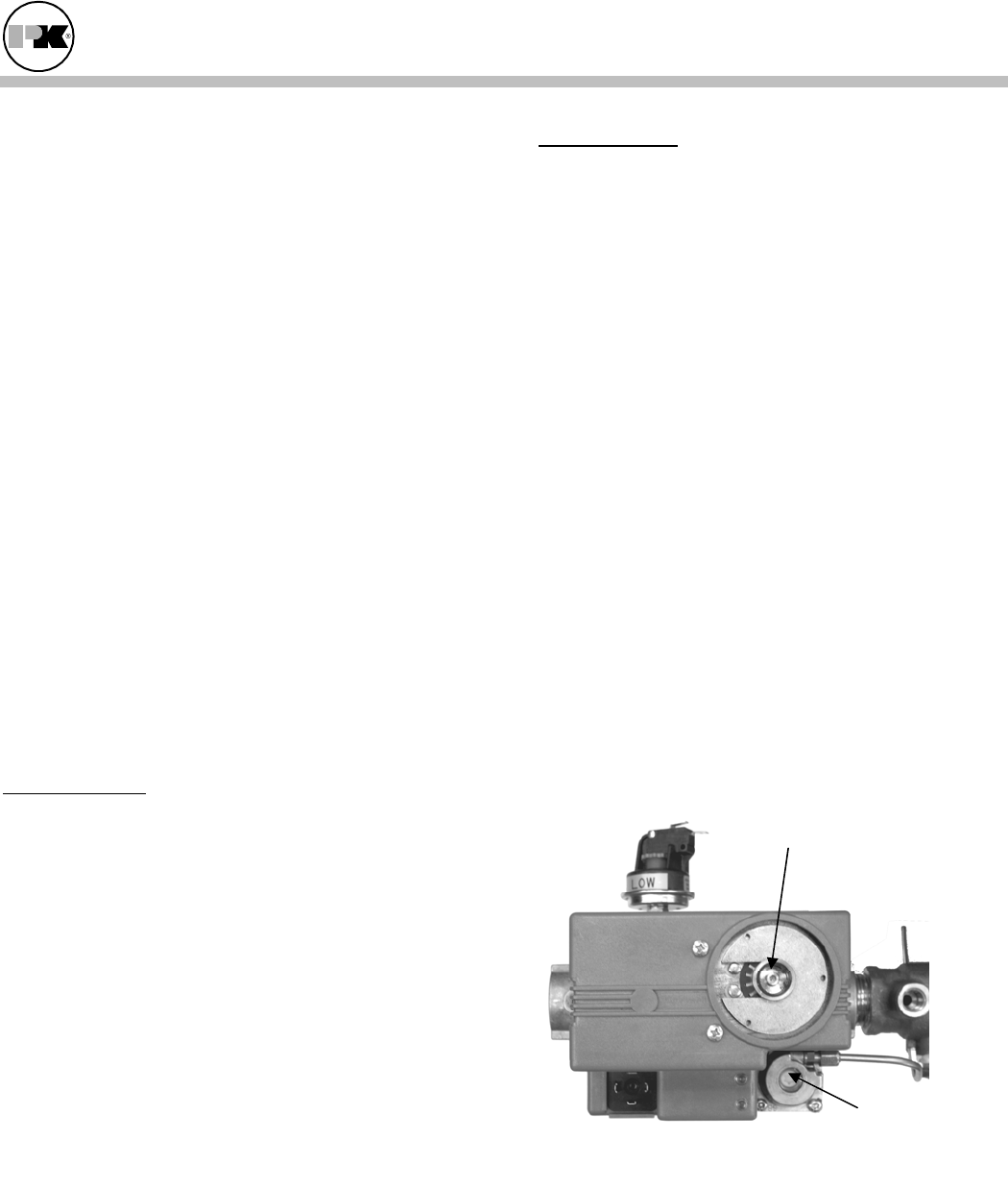

C750/900/10500 Adjusting Low and High

High fire adjustment

Low fire adjustment