10

INSTALLATION IN EXISTING CONSTRUCTION

(continued)

MOUNTING

PLATE

MOUNTING

HOLE (2)

ELBOW

FIGURE 36

MOUNTING

PLATE

INLET

FIGURE 37

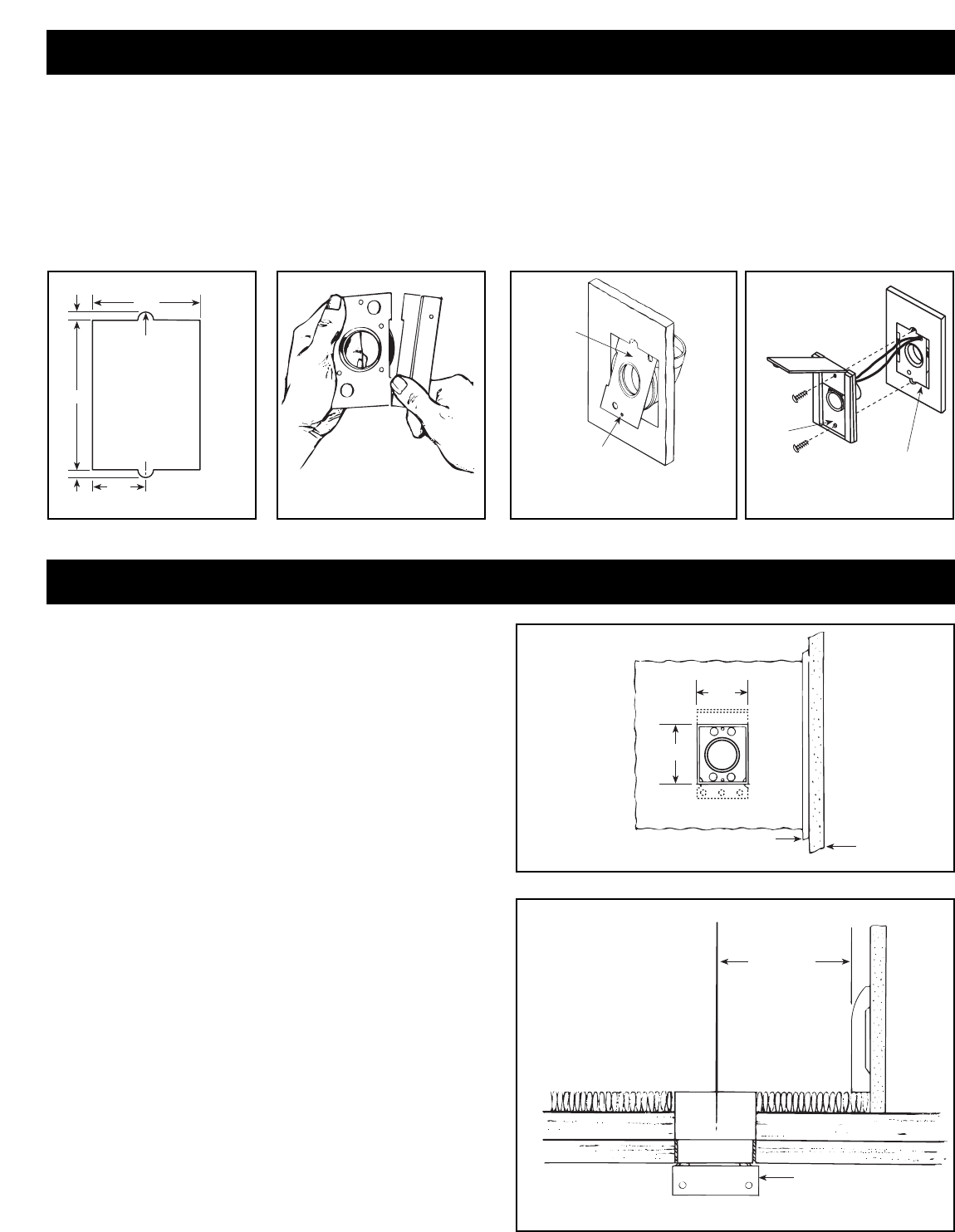

1. Make cutout according to dimensions in Figure 34.

2. Refer to Figure 35. Break off nail plate at scored line.

3. Refer to Figure 36. Glue elbow to mounting plate, place

assembly into cutout, and attach elbow to tubing inside

the wall.

4. Make sure mounting holes are exactly at top and bottom.

1

3

/8"

1

/4"

3

/8" DIA.

3

/8" DIA.

1

/4"

2

3

/4"

3

7

/8"

FIGURE 34 FIGURE 35

MODEL 330N WALL INLET INSTALLATION (329 Rough-in)

5. Connect 2-conductor low voltage wire to terminal screws on

back of wall inlet.

6. Refer to Figure 37. Align inlet mounting holes with mounting

plate holes, place inlet into mounting plate, and secure with

provided screws. NOTE: If 382-S shorter radius elbow is

used, it may be necessary to use the short mounting screw to

avoid interference with elbow.

FLOOR INLET INSTALLATION IN NEW & EXISTING CONSTRUCTION

1. Refer to Figures 38 and 39. After floor inlet location has been

selected, cut a 3

1

⁄16" x 2

9

⁄16" square hole in floor. Center line of

inlet must be located at least 2

1

⁄2" from wall to allow cover to

be opened when hose is inserted.

2. Determine direction of tubing and attach appropriate flanged

fitting to mounting bracket with four (4) screws supplied. Be

sure mounting bracket flange does not interfere with

tubing and seal is securely in place.

3. Refer to Figure 40. Position bracket with frame and flanged

fitting assembly into cutout from below and secure to sub

floor.

4. Refer to Figure 41. Large end of Model 399 extension sleeve

should be cut to length to allow proper seating of inlet against

floor or carpet.

5. Refer to Figure 42. Pull low-voltage 2-conductor wire through

mounting bracket and attach to terminal screws on back of

floor inlet. Cement extension sleeve to model 360 inlet. Insert

extension sleeve through vinyl gasket in mounting bracket

and firmly seat into flanged fitting.

6. For convenience of operation, floor inlet should be installed to

open back toward wall.

7. Refer to Figure 40. Secure floor inlet in place with two screws.

MOLDING

WALL

TOP VIEW

2

9

/16"

3

1

/16"

FIGURE 38

2

1

/2" MIN.

APPROX.

SIDE VIEW

MOUNTING BRACKET

FLANGE

FIGURE 39

MODEL 360 SERIES INLETS (361 Rough-in)