10-10

Page 33

2008-10-01

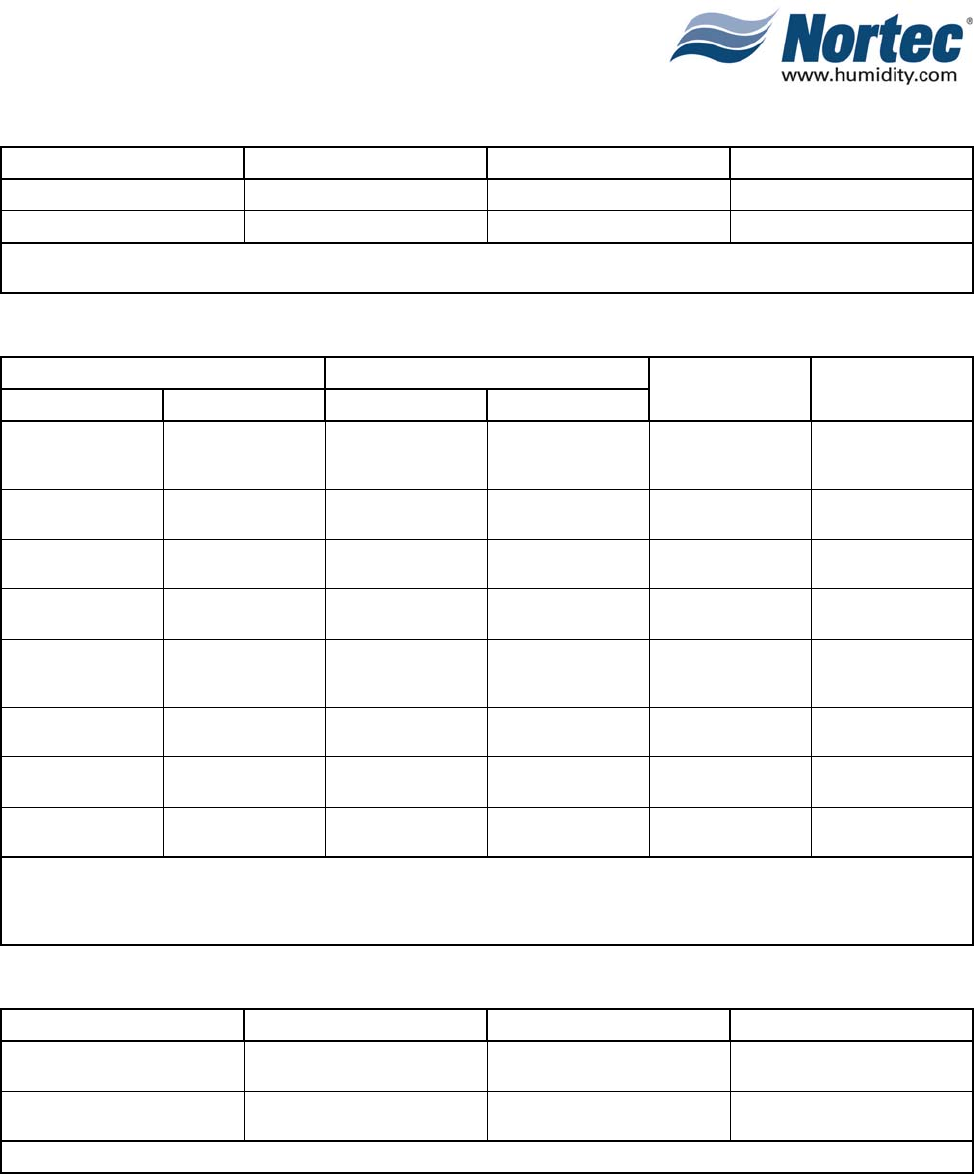

Table 11. Steam Line Material

Table 12. Recommended Material and Size for Steam Run

Table 13. Recommended Condensate Line at Distributor(s)

Steam Hose Copper Tube Stainless Steel Tube

Short run < 10 feet (3 m) yes yes yes

Long run > 10 feet (3 m) yes yes

NOTE: Steel, Iron and aluminum tubing or pipe must not be used for the steam distribution lines with these humidifiers.

Plastic tubing and pipe also must not be used for steam distribution lines.

Load Steam Run

Steam Line

Material

Steam Line

Description

lb/hr kg/hr ft m

0-30 0-13 0-10 0-3 Copper Tube ¾" MED-L

Tubing

(f" OD)

0-30 0-13 10 + 3 + Copper Tube 1"MED-L Tubing

(1c" OD)

0-30 0-13 0-10 0-3 Stainless Steel

Tube

f" Tube x

0.049" thick.

0-30 0-13 10 + 3 + Stainless Steel

Tube

1c"Tube x

0.049” thick.

30-100 13-45 0-20 0-6 Copper Tube 1½" MED-L

Tubing (1e"

OD)

30-100 13-45 20 + 6 + Copper Tube 2"MED-L Tubing

(2c"OD)

30-100 13-45 0-20 0-6 Stainless Steel

Tube

1¾" Tube x

0.065" thick.

30-100 13-45 20 + 6 + Stainless Steel

Tube

2" Tube x

0.065" thick.

NOTE: Options shown in a bold-italic font require that reducers be used at both ends. These extra large sizes are to

allow for better condensation removal in long steam runs. These sizes do not permit the use of hose couplings

to connect either humidifier or distributors.

NOTE: Insulate all copper or stainless steel steam lines with minimum one inch high temperature insulation.

Dispersion Method Condensate Hose Copper Tube Stainless Steel Tube

1 x Steam Distributor d" NORTEC 1328840 ¼" MED-L Tubing (d"

OD)

d" Tube 0.049" thick.

3 x Steam Distributor* d" NORTEC 1328840 ½" MED-L Tubing

(f

" OD)

e" Tube 0.049" thick

NOTE: When using more than one distributor, the condensate line should be trapped before it is joined together.