27

thermometer on the supply air side must be

shielded from direct radiation from the heat

exchanger to avoid false readings. Adjust all

registers and duct dampers to the desired posi-

tion and run the furnace for fifteen minutes

before taking any temperature readings. The

temperature rise is the difference between the

supply and return air temperatures.

For typical duct systems, the temperature rise

will fall within the range specified on the rating

plate with the blower speed at the factory recom-

mended setting. If the temperature rise mea-

sured is outside the range specified, it may be

necessary to change the blower speed. Lower

blower speeds will increase the temperature rise

and higher blower speeds will decrease the

temperature rise.

The furnace is equipped with a multispeed mo-

tor. Heating and cooling speed selection is made

by moving the leads on the integrated control

board located in the furnace. The wiring diagram

on the furnace and Figures 25, 26 and 27 show

the speed taps for adjusting motor speed.

If it is desired that the blower operate at the

same speed for heating and cooling, tape off the

terminal of the unused blower wire. Install the

jumper wire, found in the plastic instruction bag,

across the HEAT and COOL taps on the control

board. Reconnect the desired blower tap to the

piggyback quick connect.

The blower control is designed to start the

circulating air blower 30 seconds after the gas

valve is opened. The blower control is factory

wired to turn the blower motor off 120 seconds

after the gas valve is closed. This timing can be

changed using the BLOWER OFF timing switch

opposite the terminal block on the control board.

(See Figure 25.)

Verifying Burner Operation

To verify operation of the burners, make sure

that the blower compartment door is in place and

that there is power to the furnace. Set the

thermostat above room temperature and ob-

serve the ignition sequence. The flame can be

observed through the small clear window on the

burner box. The burner flame should carry over

between all burners. The flames should be blue,

without yellow tips. Flames should extend from

each burner without lifting, curling, or floating.

After verifying ignition, set the thermostat below

room temperature and verify that the burner

flame extinguishes completely.

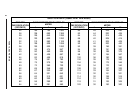

Use the following procedure to determine the

firing rate:

1. Shut off all other gas fired appliances.

2. Start the furnace and allow it to run for at

least three minutes.

3. Measure the time (in seconds) required for

the gas meter to complete one revolution.

4. Convert the time per revolution to cubic feet

of gas per hour using Table 12.

5. Multiply the gas flow rate in cubic feet per

hour by the heating value of the gas in Btu

per cubic foot to obtain the firing rate in

Btuh. Example:

• Time for 1 revolution of a gas meter with

a 1 cubic foot dial = 40 seconds.

• From Table 9 read 90 cubic feet per hour

of gas.

• Heating value of the gas (obtained from

gas supplier) = 1040 Btu per cubic foot.

• Firing rate = 1040 x 90 = 93,600 Btuh.

6. Adjustments to the firing rate can be

made by adjusting the gas manifold

pressure. See the High Altitude

Application section for additional

information of firing rate at elevations

above 2000 ft.

The manifold pressure must be set to the appro-

priate value for your installation. Refer to either

Table 7 for natural gas or Table 8 for LP/propane

gas to verify the manifold pressure setting re-

quired for your particular installation. To adjust

the manifold pressure, remove the regulator cap

and turn the adjusting screw clockwise to in-

crease pressure or counterclockwise to reduce

pressure. Replace the regulator cap after adjust-

ments are complete.

!

CAUTION:

Do not re-drill the burner orifices. If

the orifice size must be changed, use

only new orifices.

Verifying and Adjusting

Temperature Rise

Verify that the temperature rise through the

furnace is within the range specified on the

furnace rating plate. Temperature rises outside

the specified range could result in premature

heat exchanger failure.

Place thermometers in the return and supply air

stream as close to the furnace as possible. The