23

W415-0319 / D / 08.03.05

White / grey film

forms on the glass

of the optional cata-

lytic door.

Sulphur from fuel is being

deposited on glass, logs or

combustion chamber sur-

faces.

- clean the glass with a recommended gas fireplace glass cleaner.

DO NOT CLEAN GLASS WHEN HOT.

If deposits are not cleaned off regularly, the glass may become

permanently marked.

Pilot goes out

while standing;

Main burner is in

'OFF' position.

Gas piping is undersized. - turn on all gas appliances and see if pilot flame flutters, dimin-

ishes or extinguishes, especially when main burner ignites. Monitor

appliance supply working pressure.

- check if supply piping size is to code. Correct all undersized piping.

Flames are con-

sistently too large

or too small.

Carboning occurs.

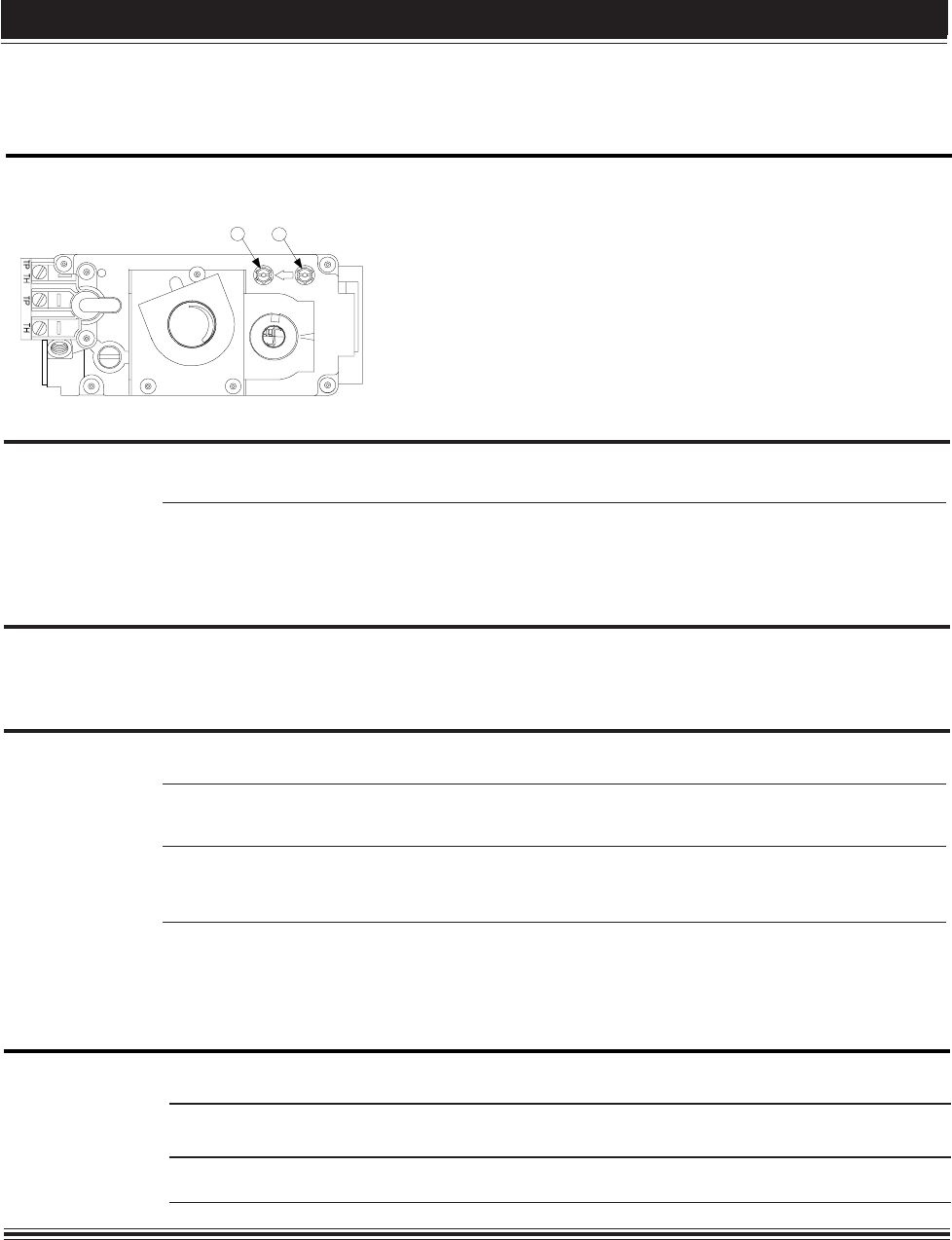

- check pressure readings:

Inlet pressure can be checked by turning screw (A) counter-clock-

wise 2 or 3 turns and then placing pressure gauge tubing over the

test point. Check with burner operating on "HI". Gauge should read

7" (minimum 4.5") water column for natural gas or 13" (11" mini-

mum) water column for propane.

Outlet pressure can be checked the same as above using screw

(B). Check with burner operating on "HI". Gauge should read 3.5"

water column for natural gas or 10" water column for propane.

AFTER TAKING PRESSURE READINGS, BE SURE TO TURN

SCREWS CLOCKWISE FIRMLY TO RESEAL. DO NOT OVERTORQUE.

Leak test with a soap and water solution.

Unit is over-fired or under-

fired.

P

I

A

B

P

I

L

O

T

N

O

L

O

T

H

I

L

O

F

F

O

Remote wall

switch is in "OFF"

position; main

burner comes on

when gas knob is

turned to "ON" po-

sition.

Wall switch is mounted up-

side down

- reverse.

Faulty valve.

- replace.

- replace.Remote wall switch is

grounding.

- check for ground (short); repair ground or replace wire.Remote wall switch wire is

grounding.

Exhaust fumes

smelled in room,

headaches.

- increase fresh air supply. (Use one of the methods described in

ANSI Z223.1 Section 5.3 or the applicable local code.)

Not enough combustion air.

- increase fresh air supply. (Use one of the methods described in

ANSI Z223.1 Section 5.3 or the applicable local code.)

Not enough ventilation air.

- check CO output from catalytic tiles. See Maintenance Section.

Replace if necessary.

Catalytic tile is masked (con-

taminated by dust, paint

fumes).

Flame is impinging on the

logs or combustion cham-

ber.

- check that the logs are correctly positioned.

- open air shutter to increase the primary air. See air shutter open-

ings, page 13.

- check the input rate: check the manifold pressure and orifice size

as specified by the rating plate values.

SYMPTOM PROBLEM TEST SOLUTION

Carbon is being

deposited on logs

or combustion

chamber surfaces.

Air shutter has become

blocked

- ensure air shutter opening is free of lint or other obstructions.

Flame is impinging on the

logs or combustion cham-

ber.

- check that the logs are correctly positioned.

- open air shutter to increase the primary air. See air shutter open-

ings, page 13.

- check the input rate: check the manifold pressure and orifice size

as specified by the rating plate values.