4

W415-0619 / A /08.09.07

16

3

/

4

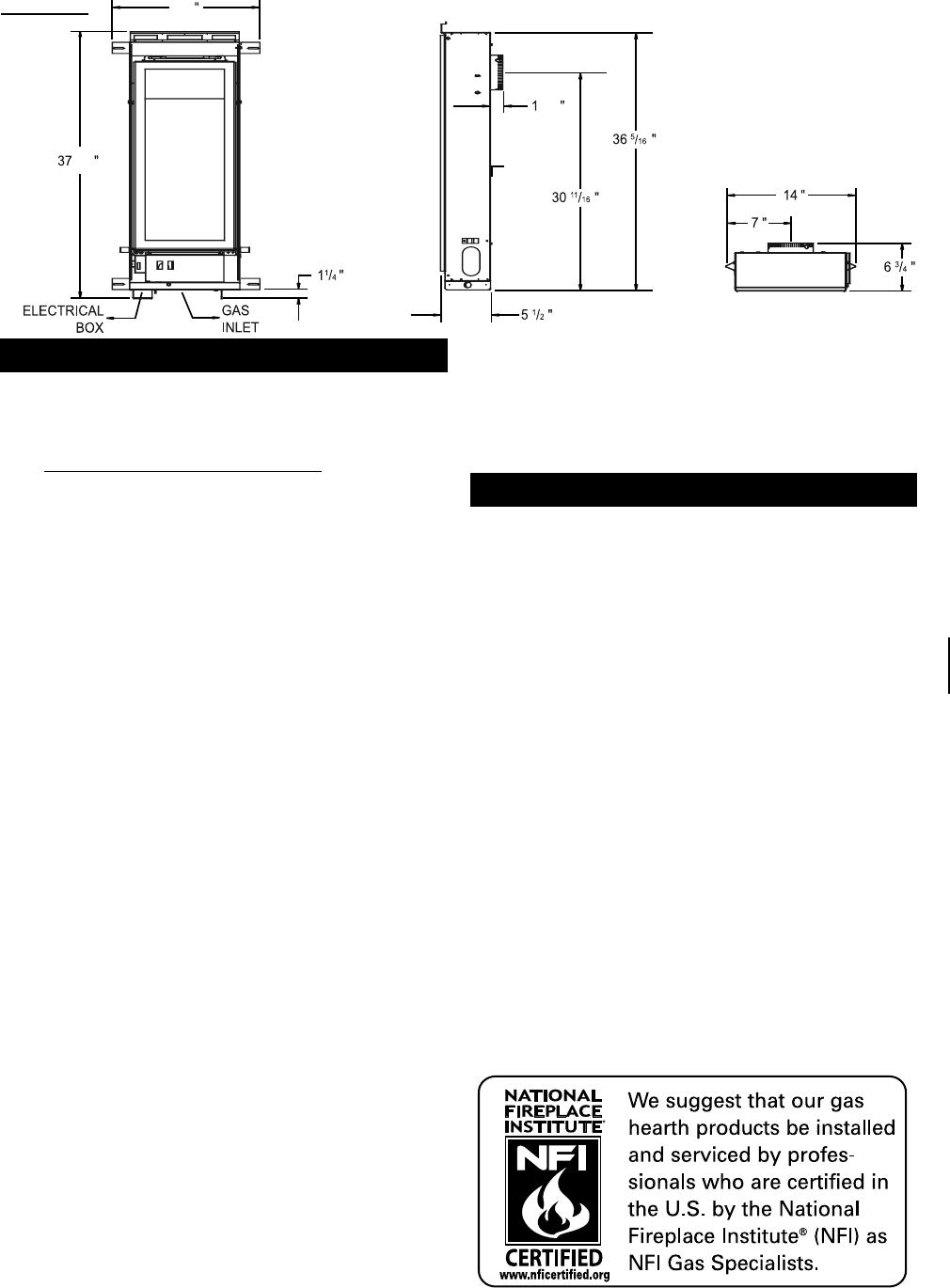

Minimum clearance to combustible construction from

fi replace and vent surfaces:

Fireplace framing: - 6” to top

- 0” to stand-offs (rear and sides)

Vent pipe: - 1”

Recessed depth: - 7”

FIGURE 1

THIS GAS FIREPLACE SHOULD BE INSTALLED AND

SERVICED BY A QUALIFIED INSTALLER to conform with

local codes. Installation practices vary from region to region

and it is important to know the specifi cs that apply to your

area, for example: in Massachusetts State:

• The fi replace damper must be removed or welded in the open

position prior to installation of a fi replace insert or gas log.

• A carbon monoxide detector is required in all rooms containing

gas fi red appliances.

• The appliance off valve must be a “T” handle gas cock.

• The fl exible connector must not be longer than 36 inches.

• The appliance is not approved for installation in a bedroom or

bathroom unless the unit is a direct vent sealed combustion

product.

• WARNING: This product must be installed by a licensed

plumber or gas fi tter when installed within the commonwealth of

Massachusetts.

In absence of local codes, install to the current CAN/CGA

-B149 Installation Code in Canada or to the National Fuel

Gas Code, ANSI Z223.1, and NFPA 54 in the United States.

Suitable for mobile home installation if installed in accordance

with the current standard CAN/CSA Z240MH Series, for gas

equipped mobile homes, in Canada or ANSI Z223.1 and NFPA

54 in the United States.

The fireplace and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of 1/2 psig (3.5 kPa). The fi replace must be isolated from the

gas supply piping system by closing its individual manual

shutoff valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.5 kPa).

When the fi replace is installed directly on carpeting, vinyl tile

or other combustible material other than wood fl ooring, the

fi replace shall be installed on a metal or wood panel extending

the full width and depth.

Purge all gas lines with the glass door of the fi replace

open. Assure that a continuous gas fl ow is at the burner

before closing the door.

Under extreme vent confi gurations, allow several minutes

(5-15) for the fl ame to stabilize after ignition.

Provide adequate ventilation and combustion air.

Provide adequate accessibility clearance for servicing and

operating the fi replace. Never obstruct the front opening of

the fi replace.

Objects placed in front of the fi replace must be kept a

minimum of 48” from the front face of the unit.

GENERAL INSTRUCTIONS

GENERAL INFORMATION

FOR YOUR SATISFACTION, THIS FIREPLACE HAS BEEN

TEST-FIRED TO ASSURE ITS OPERATION AND QUALITY!

Maximum input is

6,000 BTU/hr for both natural gas and

propane. When the fi replace is installed at elevations above

4,500ft, and in the absence of specifi c recommendations

from the local authority having jurisdiction, the certifi ed high

altitude input rating shall be reduced at the rate of 4% for

each additional 1,000ft. Maximum output for both natural

gas and propane is 4,680 BTU/hr at an effi ciency of 78%.

Minimum inlet gas supply pressure is 4.5 inches water column

for natural gas and 11 inches water column for propane.

Maximum inlet gas pressure is 7 inches water column for

natural gas and 13 inches water column for propane. Manifold

pressure under fl ow conditions is 3.5 inches water column for

natural gas and 10 inches water column for propane.

This fi replace is approved for bathroom, bedroom and bed-

sitting room installations and is suitable for mobile home

installation. The natural gas model can only be installed in

a mobile home that is permanently positioned on its site and

fueled with natural gas.

This fireplace may be installed in an aftermarket

permanently located, manufactured (mobile) home, where

not prohibited by local codes.

This fi replace is only for use with the type of gas indicated

on the rating plate. This fi replace is not convertible for

use with other gases, unless a certifi ed kit is used.

Expansion / contraction noises during heating up and

cooling down cycles are normal and are to be expected.

1

/

4