5

W415-0153 / A / 10.29.01

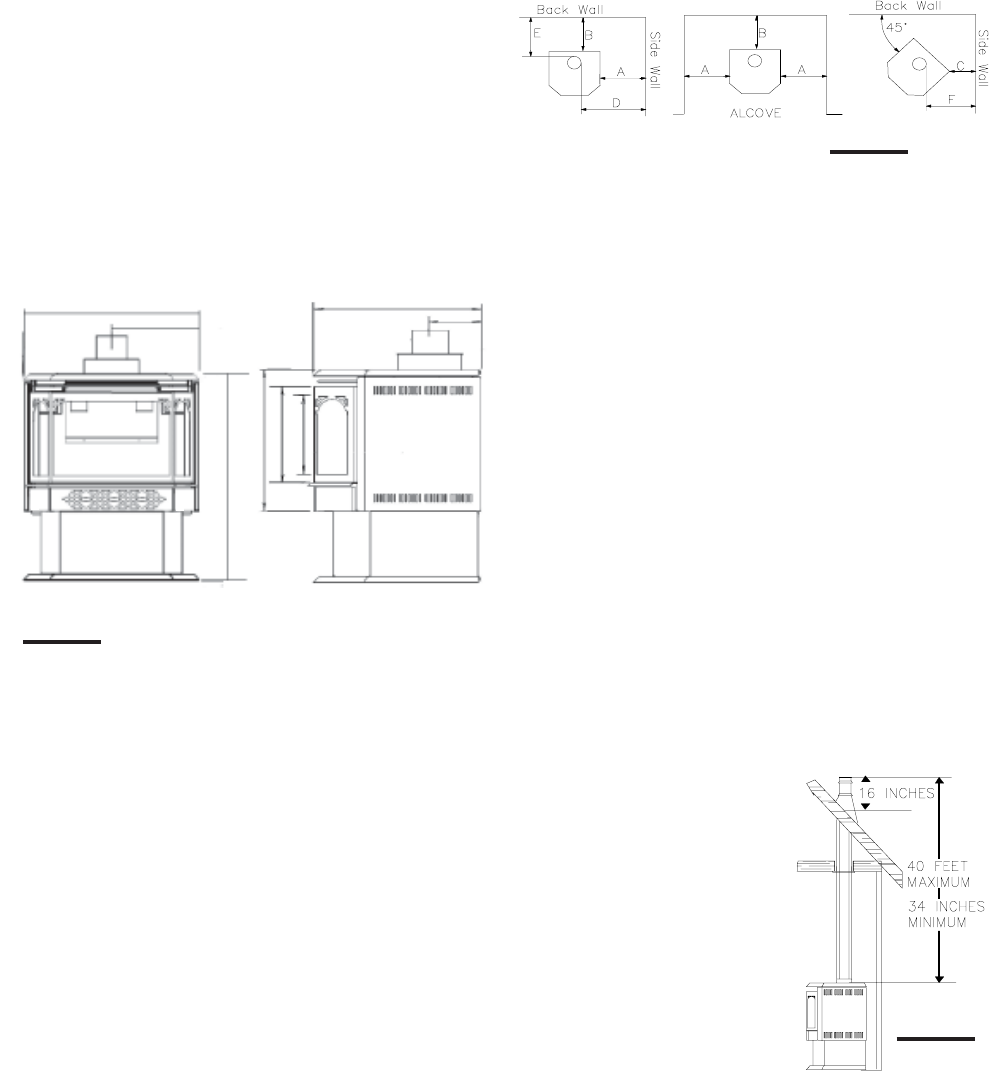

MAINTAIN THESE MINIMUM CLEARANCES TO

COMBUSTIBLES:

A. 7" D. 14

3

/

4

"

B. 2" E. 4"

C. 1"

* F. 9½"

NO ADDITIONAL FLOOR PROTECTION IS REQUIRED

MINIMUM

20" FROM STOVE TOP TO CEILING

*AT A DISTANCE OF 1" FROM THE WALL, ACCESS TO THE BLOWER

SWITCH

, ON-OFF SWITCH OR THE BLOWER POWER CORD MAY

NOT

BE PRACTICAL.

A terminal shall not terminate directly above a sidewalk

or paved driveway which is located between two sin-

gle family dwellings and serves both dwellings. Local

codes or regulations may require different clearances.

Do not allow the inside liner to bunch up on horizontal or

vertical runs and elbows. Keep it pulled tight. A 1-1/4" air

gap all around between the inner liner and outer stove pipe

is required for safe operation.

Use a firestop when penetrating interior walls, floor or ceil-

ing.

LOCATION AND CLEARANCES

Provide adequate ventilation and combustion air.

Provide adequate accessibility clearance for servicing

and operating the stove.

Never obstruct the front opening of the stove.

GDS28 AND GS28:

As long as clearance to combustibles is kept within the

required distances, the most desirable and beneficial lo-

cation for a Napoleon stove is in the centre of a building,

thereby allowing the most efficient use of the heat created.

The location of windows, doors and the traffic flow in the

room where the stove is to be located should be consid-

ered. If possible, you should choose a location where the

vent will pass through the house without cutting a floor or

roof joist.

FIGURE 2

VENTING LENGTHS AND AIR TERMI-

NAL LOCATIONS

Use only Wolf Steel or Simpson Dura-Vent Model DV-GS

venting components. Minimum and maximum vent lengths,

for both horizontal and vertical installations, and air termi-

nal locations for either system are set out in this manual

and must be adhered to. For Simpson Dura-Vent, follow

the installation procedure provided with the venting com-

ponents. Both Wolf Steel and Simpson Dura-Vent venting

components may have a 0" rise per foot on horizontal runs.

When using Wolf Steel venting components, use only the

following vent kits: WALL TERMINAL KIT GD175 (7-1/2' of

venting included), or 1/12 TO 7/12 PITCH ROOF TERMINAL

KIT GD110, 8/12 TO 12/12 ROOF TERMINAL KIT GD111,

FLAT ROOF TERMINAL KIT GD112 or STOVE PERISCOPE

KIT GD180 (for wall penetration below grade) in conjunc-

tion with the appropriate venting components.

For optimum performance, it is recommended that all

horizontal runs have a minimum ¼ inch rise per foot.

DIRECT VENT SPECIFICS - GDS28

These vent kits allow for either

horizontal or vertical venting of

the stove. FIGURES 3, 4, & 5.

The maximum number of 4"

flexible connections is two hori-

zontally or three vertically (ex-

cluding the stove and the air

terminal connections).

When terminating vertically, the

minimum vertical rise is

34 inches above the stove and

the maximum vertical rise is

40 feet.

Deviation from the minimum vertical vent length can

create difficulty in burner start-up and/or carboning.

Use an adjustable pipe as the final length of rigid pip-

ing to the stove for ease of installation.

FIGURE 1

15"

WINDOW OPENING

11¼"

22½"

26

3

/

4

"

7"ø AIR

INTAKE

FIGURE 3

17

3

/

4

"

12"

10"

4"ø

FLUE

18½"

5½"

GAS LINE ACCESS HOLE

LOCATED IN PEDESTAL

BASE