Inspecting Lubrication Oil (Mechanical Seal)

1. Block the oil fill opening with a finger and roll pump to

one side to drain (Figure 18) oil into a small transparent

container.

2. If oil is cloudy (milky) or has water in it, indicates

that mechanical seal is defective or worn. Replace

mechanical seal.

Reference the following procedure and Figure 20 for the

removal of the impeller and mechanical seal.

1. Remove the 4 bolts, nuts and washers that secure,

casing cover to the casing..

Figure 20. Mechanical Seal Impeller

Removal (PX400)

2. Remove any debris that may have accumulated on

the impeller.

3. If replacement of the impeller is required, remove

impeller screw and washer.

4. Slide mechanical seal from casing cover cavity and

replace with new one.

5. Replace o-ring, impeller washer and conical lock

washer if necessary.

6. Reassemble in reverse order.

REMOVE BOLTS

4 PLACES

MECHANICAL

SEAL

IMPELLER

IMPELLER

SCREW

REMOVE NUTS

4 PLACES

CASING

O-RING

IMPELLER

WASHER

CONICAL LOCK

WASHER

CASING

COVER

MAINTENANCE

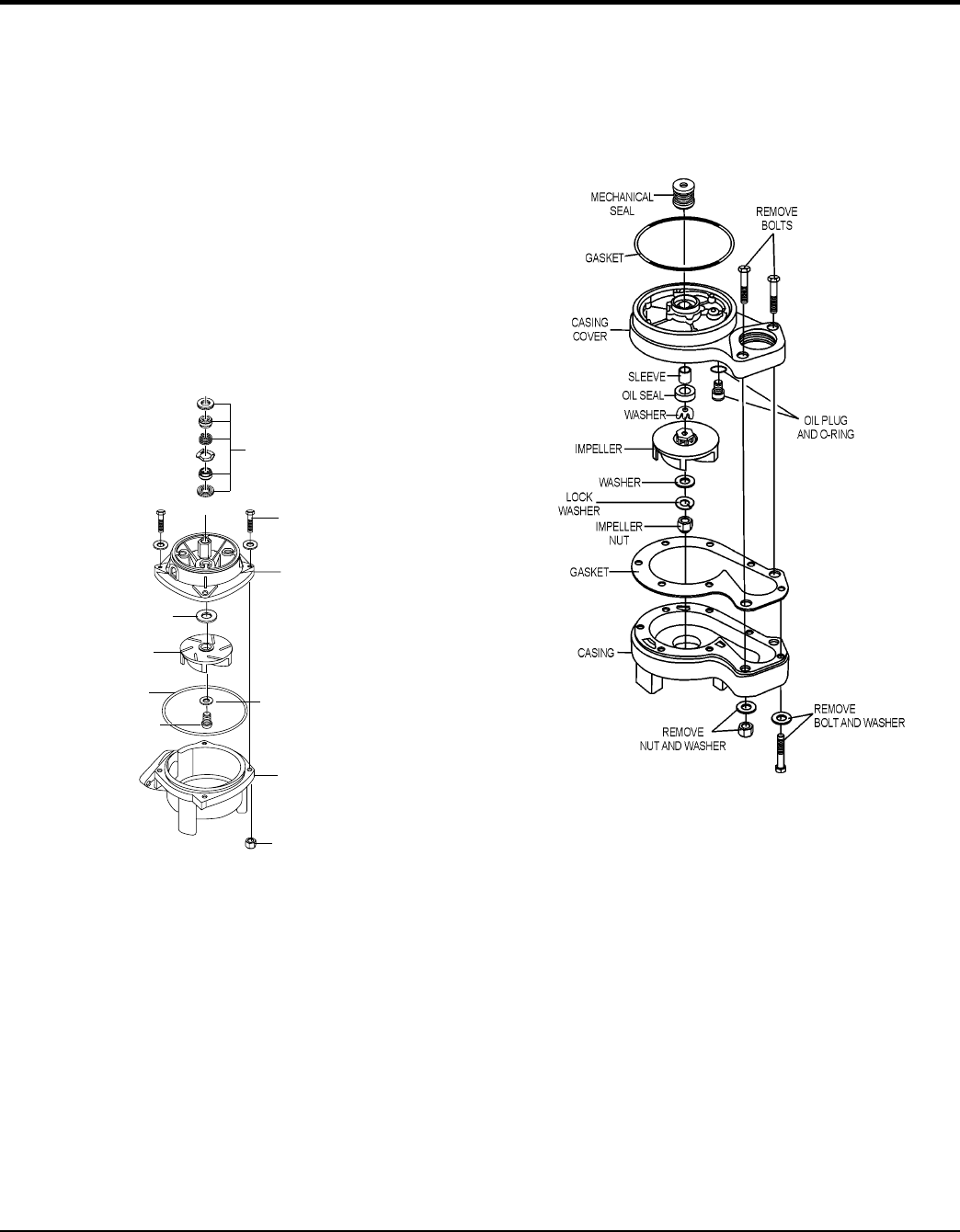

Reference the following procedure and Figure 21 for the

removal of the impeller and mechanical seal.

1. Remove the bolts securing the casing cover to the

casing .

Figure 21. Mechanical Seal Impeller

Removal (CX400)

2. Remove any debris that may have accumulated on

the impeller.

3. If replacement of the impeller is required, remove

impeller nut and washer.

4. Slide mechanical seal from casing cover cavity and

replace with new one.

5. Replace o-ring, impeller washer and washers, gaskets,

oil seal and any other pump components if necessary.

6. Reassemble in reverse order.