OC277-22

7

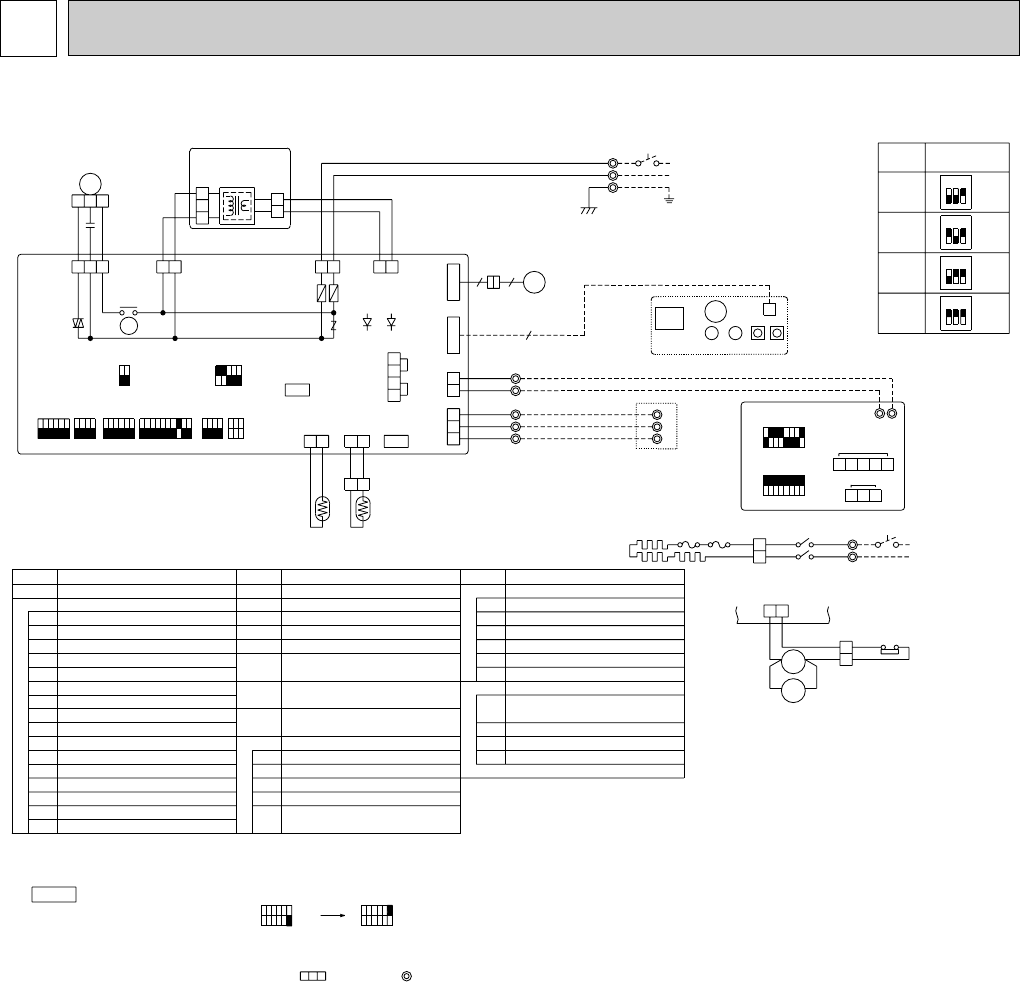

WIRING DIAGRAM

MODEL PCH24/30/36/42GK

WIRING DIAGRAM

TRANSMISSION WIRES

DC12V

ZNR

LED2LED1

F2 F1

RED

BLU

L2

L1

POWER SUPPLY

~(1PHASE)

AC208/230V 60Hz

TB2

WHT

BLK

POWER

CNDK

(WHT)

31

1

2

1

2

3

TRANS

CNSK

(RED)

(DC13.1V)

CN2S

(WHT)

P. B

(AC208/230V)

W.B

CN2

CN1

ON

OFF

ON

OFF

SW17

87654321

87654321

SW18

TRANSMISSION WIRES DC12V

123

54321

REMOCON

POWER

CN40

(WHT)

4

3

2

1

CENTRALLY

CONTROL

CN51

LOSSNAY

CN2L

TB5

BLU

BLU

1

2

REMOCON

CN22

(BLU)

SW9

12345

ON

OFFOFF

ON

12

SW3

2

1

SW7SW6SW2 SW5 SW8 SW1

1231234123456123456789101234123456

TB3

OUTDOOR UNIT

1

2

3

1

2

3

TB4

1

2

3

BRN

ORN

YLW

GRY

YLW

7

88H2

8

THERMAL FUSE<230°F/16A:30,36,42GK>

SWITCH(FUNCTION SELECTOR)

SW18

SWITCH(ADDRESS SELECTOR)

SW17

CONNECTOR(REMOTE SWITCH)

CN2

(32°F/15k",77°F/5.4k" DETECT)

SWITCH(MODEL SELECTOR)

SWITCH(OPTION)

SWITCH(MODEL SELECTOR)

SW7

SW8

SW9

SWITCH(MODEL SELECTOR)

SWITCH(EMERGENCY OPERATION)

SWITCH(ADDRESS SELECTOR)

SWITCH(FUNCTION SELECTOR)

SW2

SW1

123456

123

I.B

MF

C

RED

BLU

RED

WHT

BLK

WHT

BLK

FAN

(WHT)

135

OFF

POWER

CND

(RED)

FC

X4

X4

ON

TB6

B02A01

12

INTAKE

CN20

(RED)

OUT

DOOR

CN30

(BLU)

RT1 RT2

BLK

BLK

21

PIPE

CN21

(WHT)

21

RU

CNB

LED2

BZ

LED1 SW1SW2

R.B

9

VANE

CN6V

(WHT)

6

MV

CN2D

(WHT)

13 21

WIRELESS

CN90

(WHT)

6

GRN/YLW

88H2

88H1

BLU

53

RED

53

GR

L2

L1

H

RED

BLU

TB2

1

2

RED

WHT

FS1 FS2

POWER SUPPLY

~(1PHASE)

AC208/230V 60Hz

23

ON

1

OFF

23

ON

1

OFF

23

ON

1

OFF

23

ON

1

OFF

I.B

21

HEATER

CN24

(YLW)

YLW

YLW

78

88H1

GRY

6

5

26H

RED

RED

MODELS

SW7

LED(DC5V POWER)

LED2

VANE MOTORMV

LED(DC12V POWER)

VARISTOR

LED1

ZNR

SWITCH(COOLING ON/OFF)

SW2

SW1

LED2

RU

LED1

BZ

W.B

LED(RUN INDICATOR)

SWITCH(HEATING ON/OFF)

LED(HOT ADJUST)

BUZZER

RECEIVING UNIT

WIRELESS REMOTE CONTROLLER BOARD(OPTION)

THERMAL FUSE<243°F/16A:24GK>

TERMINAL BLOCK(REMOTE CONTROLLER

HEATER CONTACTOR

HEATER THERMAL SWITCH

HEATER

88H1,2

26H

FS1,2

TRANSMISSION LINE)

CONNECTOR(PROGRAM TIMER)

REMOTE CONTROLLER BOARD

TB6

CN1

NAME

HEATER

R.B

TRANSMISSION LINE)

TERMINAL BLOCK(REMOTE CONTROLLER

TB5

P. B

PIPE TEMP.THERMISTOR/LIQUID

RT2

RT1 ROOM TEMP.THERMISTOR

(32°F/15k",77°F/5.4k" DETECT)

TERMINAL BLOCK(POWER)

TERMINAL BLOCK(INDOOR/OUTDOOR TRANSMISSION LINE)

TB4

TB2

FAN MOTORMF

CAPACITOR(FAN MOTOR)C

FUSE(6A/250V)

RELAY(FAN MOTOR)

SWITCH(TWIN/TRIPLE SELECTOR)

FAN PHASE CONTROL

CONNECTOR(CENTRALLY CONTROL)

CONNECTOR(LOSSNAY)

F1,F2

X4

SW6

SW5

SW3

FC

CN51

CN2L

INDOOR CONTROLLER BOARD

INDOOR POWER BOARD

I.B

NAME

SYMBOL

NAME

SYMBOLSYMBOL

H

(1)Set the dip switch (SW3<I.B>) on the indoor controller board to 1 on and 2 off for cooling and 1 · 2 on for heating.

(2)Turn on outdoor unit side circuit breaker, then indoor unit side circuit breaker.

(3)During emergency operation, indoor fan runs at high speed but automatic vane does not work.

(4)Thermostat will not function. Cold air blows out for defrosting during heating thus do not operate defrosting for a long time.

(5)Emergency cooling should be limited to 10 hours maximum. (The indoor unit heat exchanger may freeze.)

(6)After every emergency operation, set all dip switch (SW3<I.B>) to OFF.

(7)Movement of the vane does not work in emergency operation, therefore you have to slowly set them manually to the appropriate position.

SW8

ON

OFF

123456

ON

OFF

1.Since the indoor fan motor(MF)is connected with 230V power, using 208V power will require a setting change of the dip switch(SW8<I.B>) on

indoor controller board as shown in fig:*1.

NOTES:

Indoor fan motor(MF)for

208V.

fig:*1

2.Since the outdoor side electric wiring may change, be sure to check the outdoor unit electric wiring for servicing.

3.Indoor and outdoor connecting wires are made with polarities, make wiring matching terminal numbers.

4.Symbols used in wiring diagram above are, :Connector, :Terminal block.

5.Emergency operation

If remote controller or microcomputer fails but there is no other trouble, emergency operation is possible by setting dip switch (SW3<I.B>)

on the indoor controller board.

6.Fasten terminal of the terminal board "TB4" equips lock system.

To remove the fasten terminal, pull it while pressing the protruding portion (locking lever) of the terminal.

Connection of the fasten terminal, protruding portion should face upward.

(1)Make sure that no other trouble exist in the outdoor unit. Trouble with the outdoor unit prevents emergency operation.

(If any trouble exists in the outdoor unit error code "P8" will be displayed on the remote controller and the trouble position will be shown on the

outdoor controller board LED. See electric wiring diagram of the outdoor unit for details.)

(2)Make sure that there is no trouble with the indoor fan.

Emergency operation will be continuous operation mode. (ON/OFF by the remote controller is not possible.)

[Check items]

[Emergency operation procedure]

24GK

30GK

36GK

42GK

OC277--1.qxp 01.12.14 13:02 Page 22