2002

JSRAE

TECHNOLOGY AWARD

2002

JSRAE

TECHNOLOGY AWARD

Japan Society of

Refrigerating and Air

Conditioning Engineers

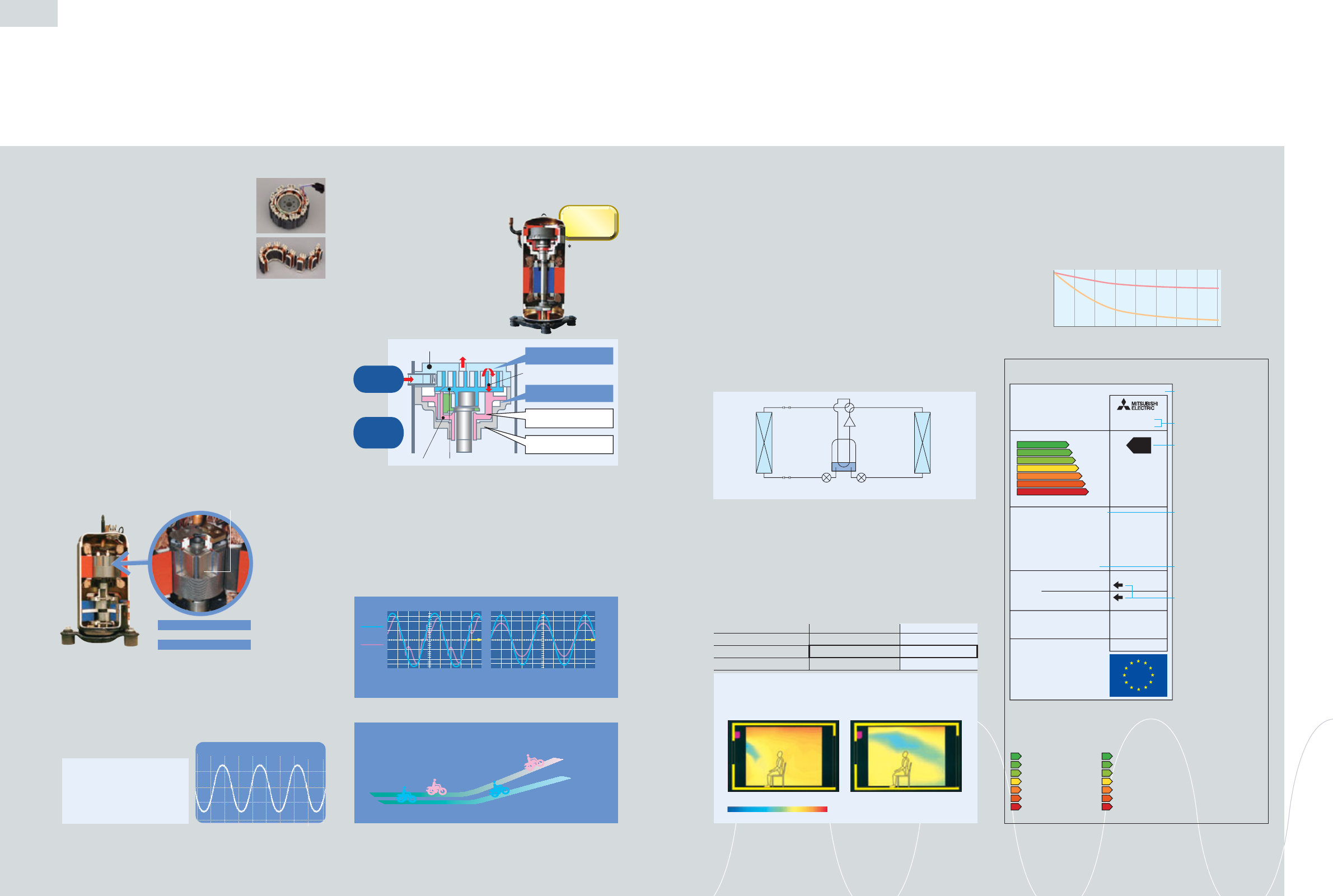

DC compressor motor (rotor)

Neodymium magnets

The reluctance DC motor has a rotor equipped with

powerful neodymium magnets. The magnetic torque

produced by the neodymium magnets and reluctance

torque results in more efficient operation.

Our unique motor, known as “Poki-Poki

Motor“ in Japan, employs joint lap

production technique. Originally

developed by Mitsubishi Electric, this

motor offers high density and high

magnetic force leading to high efficiency

and high reliability.

Magnetic torque

+

Reluctance torque

LEV1

Power

receiver

Heat

exchanger

Heat

exchanger

Compressor

LEV2

Mitsubishi Electric has developed a power receiver and

twin LEVs

(

linear expansion valves

)

that optimise the

performance of the compressor. By ensuring optimum

control in response to the operating waveform and

outdoor temperature, this technology is tailored to the

characteristics of the new refrigerant to enhance

operating efficiency.

This intelligent temperature control feature — that adjusts

airflow interval to the body depending on air outlet

temperature — allows set temperatures to be raised by 2

degrees without any loss in comfort for a 20% gain in

energy efficiency.

Power Receiver and Twin LEV Control

Joint Lap DC Motor

“Econo Cool” Energy-Saving Feature

Conventional Econo Cool

Ambient temperature 35°C35°C

Set temperature 25°C27°C

temperature 30°C 29.3°C

“Econo Cool” mode

Ensures more comfort even when the set temperature is 2°C higher

than the conventional cooling mode.

“Econo Cool” On Conventional cooling mode

Thrust gas power: minimum

Cradle scrollFrame

Secondary back-pressure chamber

minimizes thrust friction loss.

Primary back-pressure chamber

minimizes leakage loss.

Thrust friction loss: minimum

Leakage loss: minimum

Fixed scroll

The highly efficient scroll com-

pressor is equipped with a “Frame

Compliance Mechanism” that

allows movement in the axial

direction of the frame supporting

the cradle scroll. This greatly

reduces both leakage and friction

loss, ensuring very high efficiency

throughout the speed range.

Highly Efficient DC Scroll Compressor

Frame movable

in the direction

of the axis.

Remarkable

reduction

in leakage and

friction loss

Without PAM Control With PAM Control

Supply

voltage

Current

Time Time

PAM adjusts the form of the current wave so that it becomes close to that of the supply

voltage wave. High harmonics are reduced and 98% of the electricity is utilized.

Using a Motorcycle as an example

PAM

Energy savings is limited.

Fuel is wasted.

Significant energy savings.

Electricity loss reduced for

surprising energy savings.

Power is limited.

Power is insufficient

for steep hills.

Power increased.

Efficient increase

of voltage for increased power.

Conventional

Inverter

This diagram illustrates the merits of PAM Control.

PAM (Pulse Amplitude Modulation)

Electricity can be used efficiently with less loss, if the

current wave resembles the supply voltage wave. PAM is

a method for controlling the form of the current wave so

that it conforms to the supply voltage wave. With PAM

control, 98% of input power supply can be effectively used.

Magnetic Flux Vector Sine Wave Drive

By converting the motor’s electrical current waveform

from the conventional waveform to a sine wave (180° con-

ductance), this microprocessor raises the motor winding

utilization ratio and reduces energy loss for higher

efficiency.

A high-efficiency DC motor drives the fan of the

outdoor unit. It offers up to 60% greater efficiency than an

equivalent AC motor.

DC Fan Motor

70%

80%

90%

100%

Efficiency

024681012 14 16

Number of Years in Use

Flat Fin Efficiency

Conventional Fin Efficiency

*The initial period is set at 100%.

Energy Efficiency Stays Strong

( 3 times stronger than conventional Fins )

Highly Reliable Flat Fin

Thanks to the flat fin preventing clogging, the initial high

energy efficiency is maintained throughout the unit's

long lifespan.

* Available only during manual cooling operation.

Inverter & Energy Saving Technology

( PUHZ Series )

( PUHZ Series , M Series )

( M Series )

Reluctance DC Rotary Compressor

( PUHZ Series )

( PUHZ Series )

distribution

(

°C)

14 16 18 20 22 24 26 28

Perceived

Temperature

Sine-wave drive soft PWM

This produces the most efficient waveform in response to

varying compressor motor frequency. By improving

operating efficiency from low to high speeds, annual

electricity costs are reduced.

Vector-Wave Eco Inverter

The inverter has been made compact

by insert-moulding the circuit pattern

in synthetic resin. To ensure quiet

operation, soft

PWM control is used to

prevent the metallic whine associated

with conventional inverters.

Smooth wave pattern

*These classifications are for Split and Multi-Split type air conditioners.

Energy Labeling of Air Conditioners

Outdoor unit

Indoor unit

More efficient

Less efficient

Annual energy consumption,

kWh in cooling mode

(Actual consumption will depend

on how the appliance is used

and climate.)

Energy efficiency ratio

Full load (the higher the better)

Type Cooling only –

Cooling + Heating –

Air cooled –

Water-cooled –

Heat output kW

Heating performance

A: higher G: lower

Noise

(dB(A) re 1 pW)

Further information is contained

in product brochures.

All air conditioners with the cooling capacity under 12kW are concerned.

Directive defines for each type of product the energy class going from A (more efficient) to G (less efficient).

The energy efficiency class is determined in accordance with the following tables.

Norm EN 814

Air conditioner

Energy Label Directive 2002/31/EC

Classifications

Energy Efficiency Class

In cooling mode

A 3.20 < EER

B 3.20 ≥ EER > 3.00

C 3.00 ≥ EER > 2.80

D 2.80 ≥ EER > 2.60

E 2.60 ≥ EER > 2.40

F 2.40 ≥ EER > 2.20

G 2.20 ≥ EER

Energy Efficiency Class

In heating mode

A 3.60 < COP

B 3.60 ≥ COP > 3.40

C 3.40 ≥ COP > 3.20

D 3.20 ≥ COP > 2.80

E 2.80 ≥ COP > 2.60

F 2.60 ≥ COP > 2.40

G 2.40 ≥ COP

Product

Air Conditioners

A B C 1 2 3

A B C 1 2 3

A

X.Y

X.Y

X.Y

X.Y

A B C D E F G

Model Name

Energy Efficiency Class

Annual Energy Consumption

The Annual Energy Consumption is

calculated with the total input power

multiplied by an average of 500 hours

per year in cooling mode at full load.

Energy Efficiency Ratio

Higher EER means better

energy efficiency.

Type of Air Conditioner

A

B

C

D

E

G

Energy

AIR CONDITIONING SYSTEMS

Manufacturer

F

Cooling output kW

7

8