6

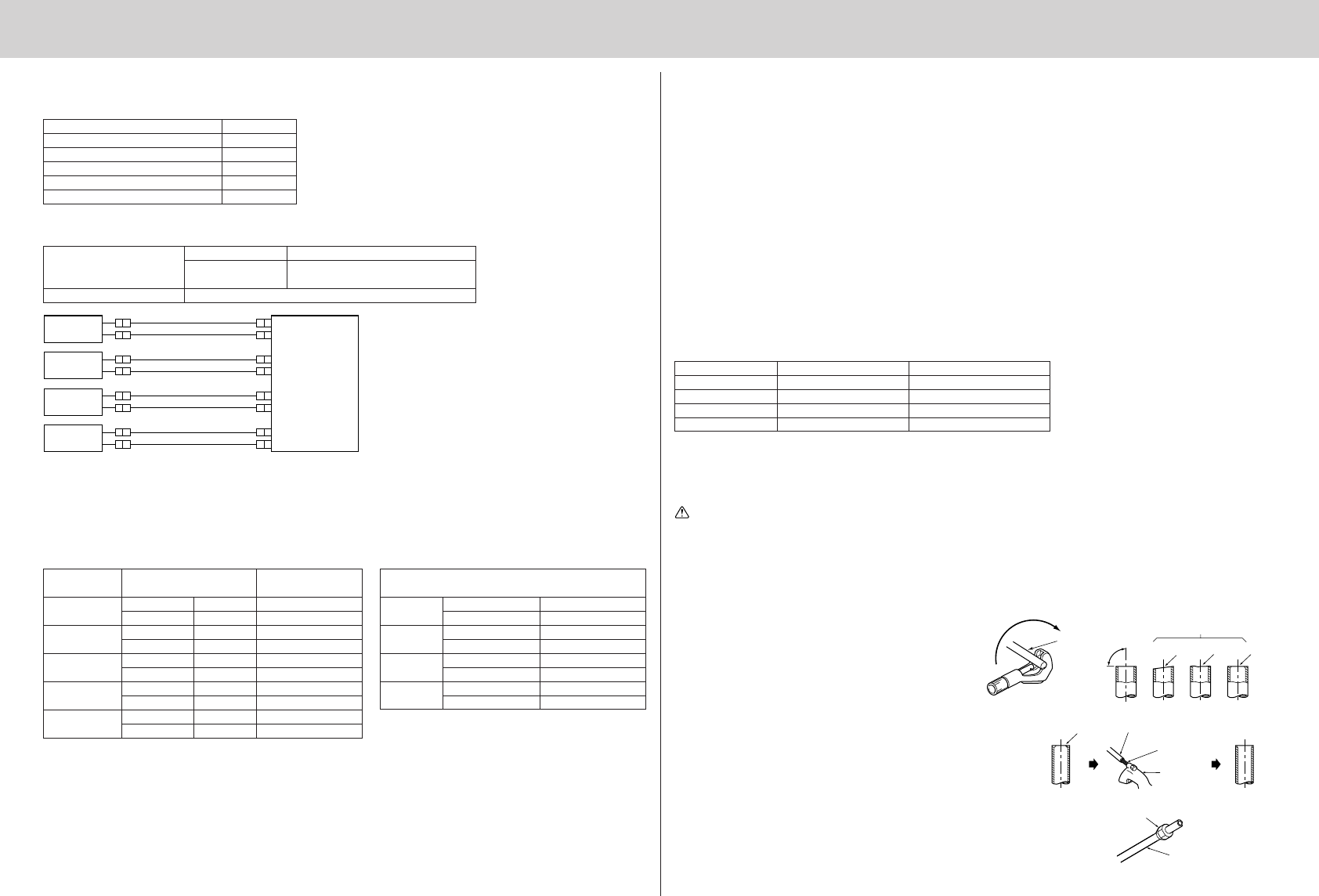

Copper

pipe

Good

No good

Tilted Uneven

Burred

Burr

Copper pipe

Spare

reamer

Pipe cutter

Flare nut

Copper pipe

5-2 FLARING WORK

• Main cause of gas leakage is defect in flaring work.

Perform flaring work correctly in the following procedure.

1. Pipe cutting

• Cut the copper pipe correctly with pipe cutter.

2. Burrs removal

• Completely remove all burrs from the cut cross

section of the pipe.

• Put the end of the copper pipe downward to pre-

vent burrs from dropping in the pipe.

3. Putting nut on

• Remove flare nuts attached to indoor and outdoor

units, then put them on pipe having completed

burr removal.

(not possible to put them on after flaring work)

• Flare nut for R410A pipe may differ from R22 pipe

depending on the diameter of pipe.

* Connections at outdoor unit are described as unit A, B, C and D below corresponding to the indica-

tion on each valve.

• If the diameter of connection pipes does not match the diameter of pipe end connections, use optional

different-diameter joints.

• When connecting the model 50 to either unit B, C or D, use optional different-diameter joints MAC-A454JP

because the valve size of gas pipes for the outdoor unit is ø9.52 mm.

• When connecting the model 22, 25 or 35 to unit A, use optional different-diameter joints MAC-A455JP be-

cause the valve size of gas pipes for the outdoor unit is ø12.7 mm.

• When connecting the model 60 to unit A, use optional different-diameter joints MAC-A456JP because the

valve size of gas pipes for the outdoor unit is ø12.7 mm.

• When connecting the model 60 to either unit B, C or D, use optional different-diameter joints PAC-SG76RJ

because the valve size of gas pipes for the outdoor unit is ø9.52 mm.

• When connecting the model 71 to unit A, use optional different-diameter joints MAC-A456JP and PAC-493PI

because the valve size of gas pipe and liquid pipe for the outdoor unit is ø12.7 mm and ø6.35 mm.

• When connecting the model 71 to either unit B, C or D, use optional different-diameter joints PAC-SG76RJ and

PAC-493PI because the valve size of gas pipe and liquid pipe for the outdoor unit is ø9.52 mm and ø6.35 mm.

PIPING PREPARATION

1If you use commercially available copper pipes, use the following table for pipe specifications.

Outside diameter Wall thickness

Liquid pipe ø6.35 mm 0.8 mm

Gas pipe ø9.52 mm 0.8 mm

Gas pipe ø12.7 mm 1.0 mm

Gas pipe ø15.88 mm 1.0 mm

2For insulation material, use 8 mm-thick heat-insulating expended polyethylene with a specific gravity of 0.045.

3Ensure that the 2 refrigerant pipes are insulated to prevent condensation.

4Refrigerant pipe bending radius must be 100 mm or more.

CAUTION:

Be sure to use the insulation of specified thickness. Excessive thickness may cause incorrect installa-

tion of the indoor unit and lack of thickness may cause dew drippage.

90°

5. INDOOR/OUTDOOR UNITS CONNECTION FINISHING AND TEST RUN

Model

Pipe size for indoor unit

Allowable

name connection pipe size

22 Liquid pipe ø6.35 mm ø6.35 mm

25 Gas pipe ø9.52 mm ø9.52 mm

35

Liquid pipe ø6.35 mm ø6.35 mm

Gas pipe ø9.52 mm ø9.52 mm

50

Liquid pipe ø6.35 mm ø6.35 mm

Gas pipe ø12.7 mm ø12.7 mm

60

Liquid pipe ø6.35 mm ø6.35 mm

Gas pipe ø15.88 mm ø15.88 mm

71

Liquid pipe ø9.52 mm ø9.52 mm

Gas pipe ø15.88 mm ø15.88 mm

Valve size for outdoor unit

Å UNIT

Liquid pipe ø6.35 mm

Gas pipe ø12.7 mm

ı UNIT

Liquid pipe ø6.35 mm

Gas pipe ø9.52 mm

Ç UNIT

Liquid pipe ø6.35 mm

Gas pipe ø9.52 mm

Î UNIT

Liquid pipe ø6.35 mm

Gas pipe ø9.52 mm

Indoor unit Î UNIT

Indoor unit Ç UNIT

Outdoor

unit

Indoor unit ı UNIT

Indoor unit Å UNIT

5-1 FLARED CONNECTIONS

PIPE LENGTH AND HEIGHT DIFFERENCE

Limits 4A80VA

Pipe length per indoor unit 25 m max.

Total pipe length for multi-system 70 m max.

Height difference 10 m max.

No. of bends per indoor unit 25 max.

Total No. of bends for multi-system 70 max.

Refrigerant adjustment .......If pipe length exceeds 40 m, additional refrigerant (R410A) charge is required.

(The outdoor unit is charged with refrigerant for total pipe length up to 40 m.)

Pipe length

Up to 40 m No additional charge is required.

Exceeding 40 m

Additional charge is required.

(Refer to the table below.)

Refrigerant to be added 20 g/m × (refrigerant piping length(m)-40)

• For pipe size, see the table below.

SELECTING PIPE SIZE

The diameter of connection pipes differs according to the type and capacity of indoor units. Match the diameters

of connection pipes for indoor and outdoor units according to the following table.

(MXZ-4A80VA)