En-6

4-3.TESTRUN

• Testrunsoftheindoorunitsshouldbeperformedindividually.Seetheinstallationmanual

comingwiththeindoorunit,andmakesurealltheunitsoperateproperly.

• If the test run with all the units is performed at once, possible erroneous connections of the

refrigerantpipesandtheindoor/outdoorunitconnectingwirescannotbedetected.Thus,be

sure to perform the test run one by one.

About the restart protective mechanism

Oncethecompressorstops,therestartpreventivedeviceoperatessothecompressorwillnot

operatefor3minutestoprotecttheairconditioner.

Wiring/piping correction function

Thisunithasawiring/pipingcorrectionfunctionwhichcorrectswiringandpipingcombination.

Whenthereispossibilityofincorrectwiringandpipingcombination,andconrmingthecombi

-

nationisdifcult,usethisfunctiontodetectandcorrectthecombinationbyfollowingtheproce

-

dures below.

Makesurethatthefollowingisdone.

• Power is supplied to the unit.

• Stopvalvesareopen.

Note:

During detection, the operation of the indoor unit is controlled by the outdoor unit. During detec

-

tion, the indoor unit automatically stops operation. This is not a malfunction.

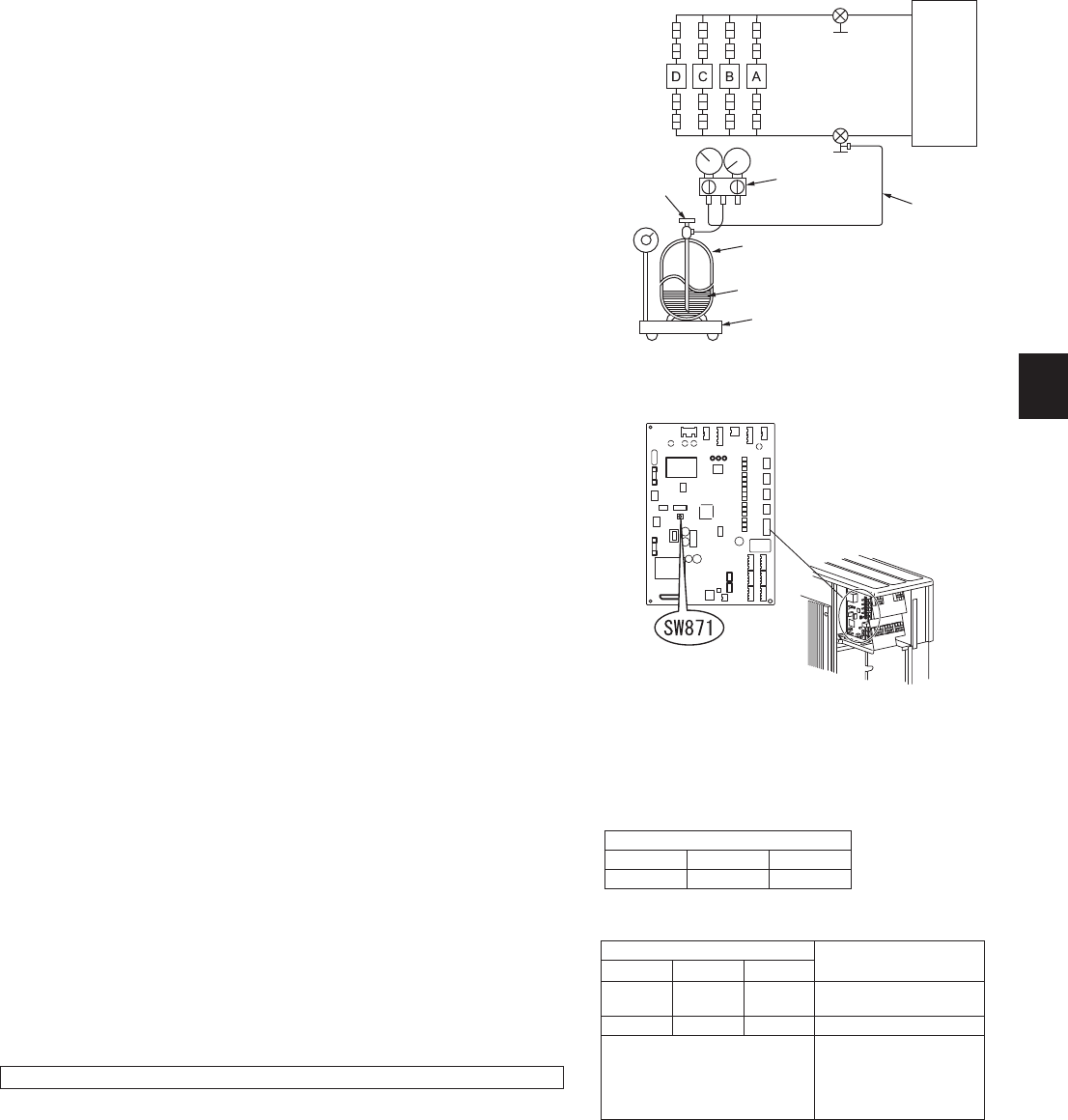

4-2.GASCHARGE

Perform gas charge to unit.

1)Connectgascylindertotheserviceportofstopvalve.

2)Performairpurgeofthepipe(orhose)comingfromrefrigerantgascylinder.

3)Replenishspeciedamountoftherefrigerant,whileoperatingtheairconditionerforcooling.

Note:

Incaseofaddingrefrigerant,complywiththequantityspeciedfortherefrigeratingcycle.

CAUTION:

When charging the refrigerant system with additional refrigerant, be sure to use liquid refriger

-

ant. Adding gas refrigerant may change the composition of the refrigerant in the system and

affect normal operation of the air conditioner. Also, charge the liquid refrigerant slowly, otherwise

thecompressorwillbelocked.

To maintain the high pressure of the gas cylinder, warm the gas cylinder with warm water (under

40°C(140°F))duringcoldseason.Butneverusenakedreorsteam.

Procedure

Pressthepiping/wiringcorrectionswitch(SW871)1minuteormoreafterturningonthepower

supply.

• Correction completes in 10 to 15 minutes. When the correction is completed, its result is

shown by LED indication. Details are described in the following table.

• Tocancelthisfunctionduringitsoperation,pressthepiping/wiringcorrectionswitch(SW871)

again.

• Whenthecorrectioncompletedwithouterror,donotpressthepiping/wiringcorrectionswitch

(SW871)again.

Whentheresultwas“cannotbecorrected”,pressthepiping/wiringcorrectionswitch(SW871)

againtocancelthisfunction.Then,conrmthewiringandpipingcombinationinaconventional

manner by operating the indoor units one by one.

• Theoperationisdonewhilethepowerissupplied.Makesurenottocontactpartsotherthan

theswitch,includingtheP.C.board.Thismaycauseelectricshockorburnbyhotpartsand

livepartsaroundtheswitch.ContactingthelivepartsmaycauseP.C.boarddamage.

• TopreventelectroniccontrolP.C.boarddamage,makesuretoperformstaticeliminationbe

-

fore operating this function.

• Thisfunctiondoesnotoperatewhentheoutsidetemperatureis0°C(32°F)orbelow.

LEDindicationduringdetection:

LED

1(Red) 2(Yellow) 3(Green)

Lighted Lighted Blinking

Resultofpiping/wiringcorrectionfunction

LED

Result

1(Red) 2(Yellow) 3(Green)

Lighted Not lighted Lighted

Completed

(Correctedsuccessfully)

Blinking Blinking Blinking Cannot be corrected

Other indications

Refer to “SAFETY PRE-

CAUTIONS WHEN LED

FLASHES”locatedbehind

theservicepanel.

4-4.EXPLANATIONTOTHEUSER

• UsingtheOPERATINGINSTRUCTIONS,explaintotheuserhowtousetheairconditioner(howtousetheremotecontroller,howtoremovetheairlters,howto

removeorputtheremotecontrollerintheremotecontrollerholder,howtoclean,precautionsforoperation,etc.).

• Recommend the user to read the OPERATING INSTRUCTIONS carefully.

Union

Stopvalve

Liquid

pipe

Indoor

unit

Stopvalvewith

serviceport

Gas

pipe

Refrigerant gas

cylinder

operatingvalve

(forR410A)

Gauge manifold

valve(forR410A)

Charge hose

(forR410A)

Refrigerant gas cylinder for R410A with siphon

Electronic scale for refrigerant charging

Refrigerant(liquid)

Outdoor

unit

Union

Union

Union

D unit is for

4B36NAonly

JG79A417H01_en.indd 6 10/12/2010 9:19:47 AM