En-5

3-2.PIPECONNECTION

1)Applyathincoatofrefrigerationoil(G)tothearedendsofthepipesand

the pipe connections of the outdoor unit.

2)Alignthecenterofthepipewiththatofthepipeconnectionsoftheoutdoor

unit,thenhandtightenthearenut3to4turns.

3)Tightenthearenutwithatorquewrenchasspeciedinthetable.

•Over-tighteningmaycausedamagetothearenut,resultinginrefriger

-

antleakage.

• Be sure to wrap insulation around the piping. Direct contact with the bare

piping may result in burns or frostbite.

3-3.INSULATIONANDTAPING

1)Coverpipingjointswithpipecover.

2)Foroutdoorunitside,surelyinsulateeverypipingincludingvalves.

3)Usingpipingtape(E),applytapingstartingfromtheentryofoutdoorunit.

•Stoptheendofpipingtape(E)withtape(withadhesiveagentattached).

•Whenpipinghavetobearrangedthroughaboveceiling,closetorwhere

the temperature and humidity are high, wind additional commercially sold

insulationtopreventcondensation.

WARNING

When installing the unit, securely

connect the refrigerant pipes before

starting the compressor.

CAUTION

When there are the ports which are

not used, make sure their nuts are

tightened securely.

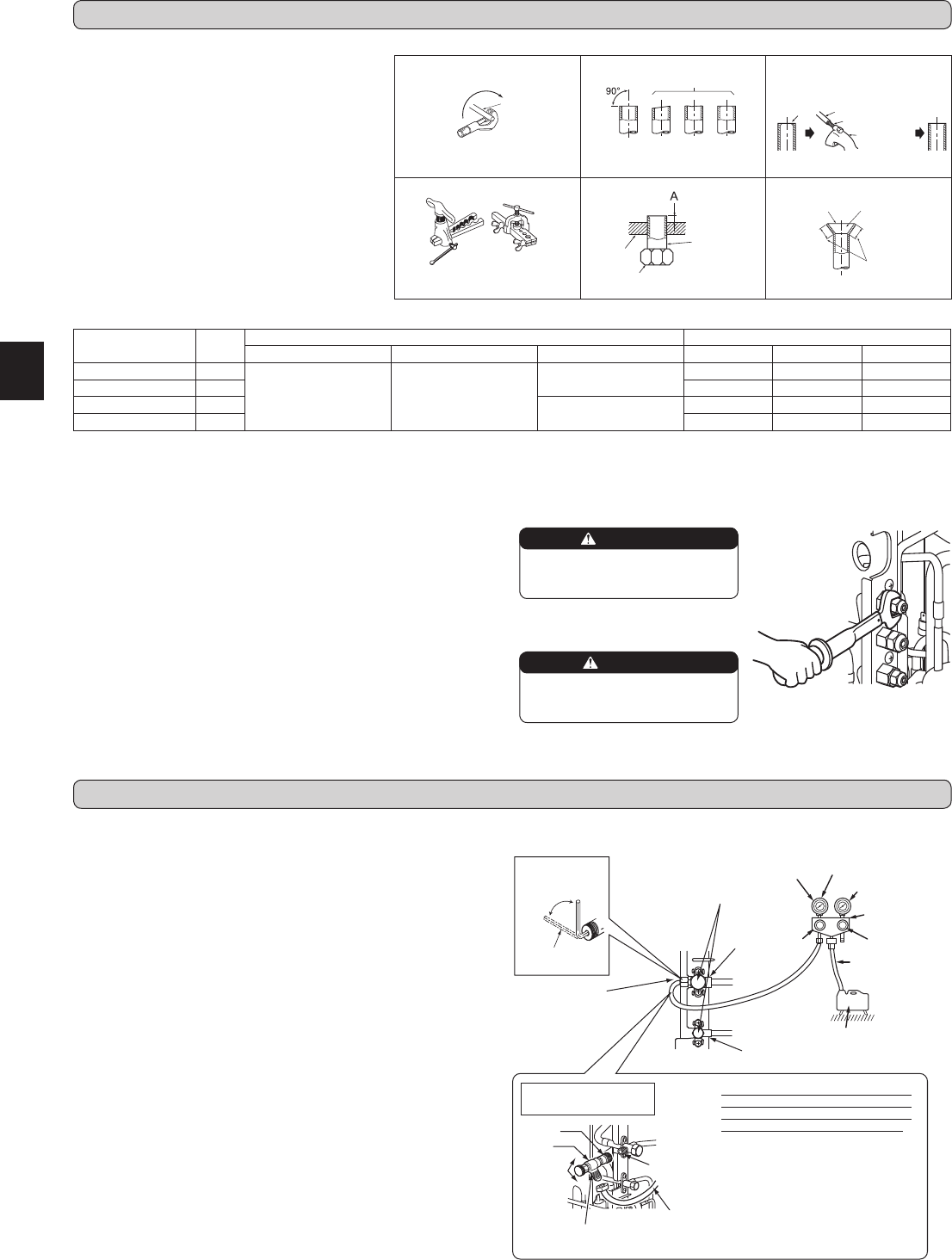

Fig. 1 Fig. 2 Fig.3

Fig. 4 Fig. 5 Fig. 6

TiltedUnevenBurred

Good

No good

Burr

Copper pipe

Spare reamer

Pipe cutter

Smooth all

around

Evenlength

all around

Inside is shin

-

ing without any

scratches.

Flare nut

Die

Copper pipe

Clutch type

Flaring tool

Wing nut type

Copper

pipe

Pipe diameter

[mm(inch)]

Nut

(mm)

A[mm(inch)] Tightening torque

Clutch type tool for R410A Clutch type tool for R22 Wing nut type tool for R22

N•m kgf•cm ft•Ib

ø6.35(1/4) 17

0 to 0.5

(0to0.02)

1.0 to 1.5

(0.04to0.06)

1.5 to 2.0

(0.06to0.08)

13.7to17.7 140 to 180 10to13

ø9.52(3/8)

22 34.3to41.2 350to420 25to30

ø12.7(1/2)

26

2.0 to 2.5

(0.08to1.0)

49.0 to 56.4 500 to 575 36to42

ø15.88(5/8)

29 73.5to78.4 750 to 800 54 to 58

3. FLARINGWORKANDPIPECONNECTION

3-1.FLARINGWORK

1)Cutthecopperpipecorrectlywithpipecutter.(Fig.1,2)

2)Completelyremoveallburrsfromthecutcrosssection

ofpipe.(Fig.3)

•Aimthecopperpipedownwardwhileremovingburrs

topreventburrsfromdroppinginthepipe.

3)Removearenutsattachedtoindoorandoutdoorunits,

thenputthemonpipehavingcompletedburrremoval.

(Notpossibletoputthemonafteraringwork.)

4)Flaringwork(Fig.4,5).Firmlyholdcopperpipeinthe

dimension shown in the table. Select A mm from the

table according to the tool selected.

5)Check

•ComparethearedworkwithFig.6.

•Ifareisnotedtobedefective,cutoffthearedsec

-

tionanddoaringworkagain.

4-1.PURGINGPROCEDURESANDLEAKTEST

4. PURGINGPROCEDURES,LEAKTEST,ANDTESTRUN

1)Removeserviceportcapofstopvalveonthesideoftheoutdoorunitgas

pipe.(Thestopvalvesarefullyclosedandcoveredincapsintheirinitial

state.)

2)Connectgaugemanifoldvalveandvacuumpumptoserviceportofstop

valveonthegaspipesideoftheoutdoorunit.

3)Runthevacuumpump.(Vacuumizeformorethan15minutes.)

4)Checkthevacuumwithgaugemanifoldvalve,thenclosegaugemanifold

valve,andstopthevacuumpump.

5)Leaveasitisforoneortwominutes.Makesurethepointerofgauge

manifoldvalveremainsinthesameposition.Conrmthatpressuregauge

shows

–

0.101MPa[Gauge](

–

760mmHg)(

–

30in.Hg).

6)Removegaugemanifoldvalvequicklyfromserviceportofstopvalve.

7)Fullyopenallstopvalvesonthegaspipeandtheliquidpipe.Operating

without fully opening lowers the performance and this causes trouble.

8)Referto1-2.,andchargetheprescribedamountofrefrigerantifneeded.

Be sure to charge slowly with liquid refrigerant. Otherwise, composition of

the refrigerant in the system may be changed and affect performance of

the air conditioner.

9)Tightencapofserviceporttoobtaintheinitialstatus.

10

)Leaktest

Serviceportcap

(Torque13.7to

17.7 N•m, 140 to

180kgf

•cm, 10 to

13

ft•lb)

Stopvalve

for GAS

Stopvalvecap

(Torque 19.6 to 29.4 N•m,

200to300kgf•cm,15to

22ft•lb)

Gauge manifold

valve(forR410A)

Compound pressure

gauge(forR410A)

–0.101MPa

[–760 mmHg

(–30in.Hg)]

Handle

Low

Handle High

Vacuumpump

(forR410A)

Charge hose

(forR410A)

*Close

*Open

Hexagonal wrench

*4 to 5 turns

Stopvalve

for LIQUID

Pressure gauge

(forR410A)

Precautions when using

thecontrolvalve

Whenattachingthecontrolvalveto

theserviceport,valvecoremayde-

form or loosen if excess pressure is

applied.Thismaycausegasleak.

Serviceport

Charge hose

(forR410A)

Body

Close

Open

Control

valve

A

Whenattachingthecontrolvalveto

theserviceport,makesurethatthe

valvecoreisinclosedposition,and

then tighten part A. Do not tighten

partAorturnthebodywhenvalve

core is in open position.

JG79A417H01_en.indd 5 10/12/2010 9:19:46 AM