dB

Only

MSZ-FA/GA25

1/2

noise

Operation has been made very silent by

improvements to the design of the fan

blades and the new grille shape. The

outdoor unit is even more silent when

outside temperature drops as it

automatically switches to low-noise

mode to reduce operating noise by 3dB.

Silent Operation

A low-noise priority function is also available

by connecting a commercially available

timer or a selector switch. When a signal is

received from the timer or the switch, the

unit runs in low-noise priority mode.

Low-Noise Priority Function

C

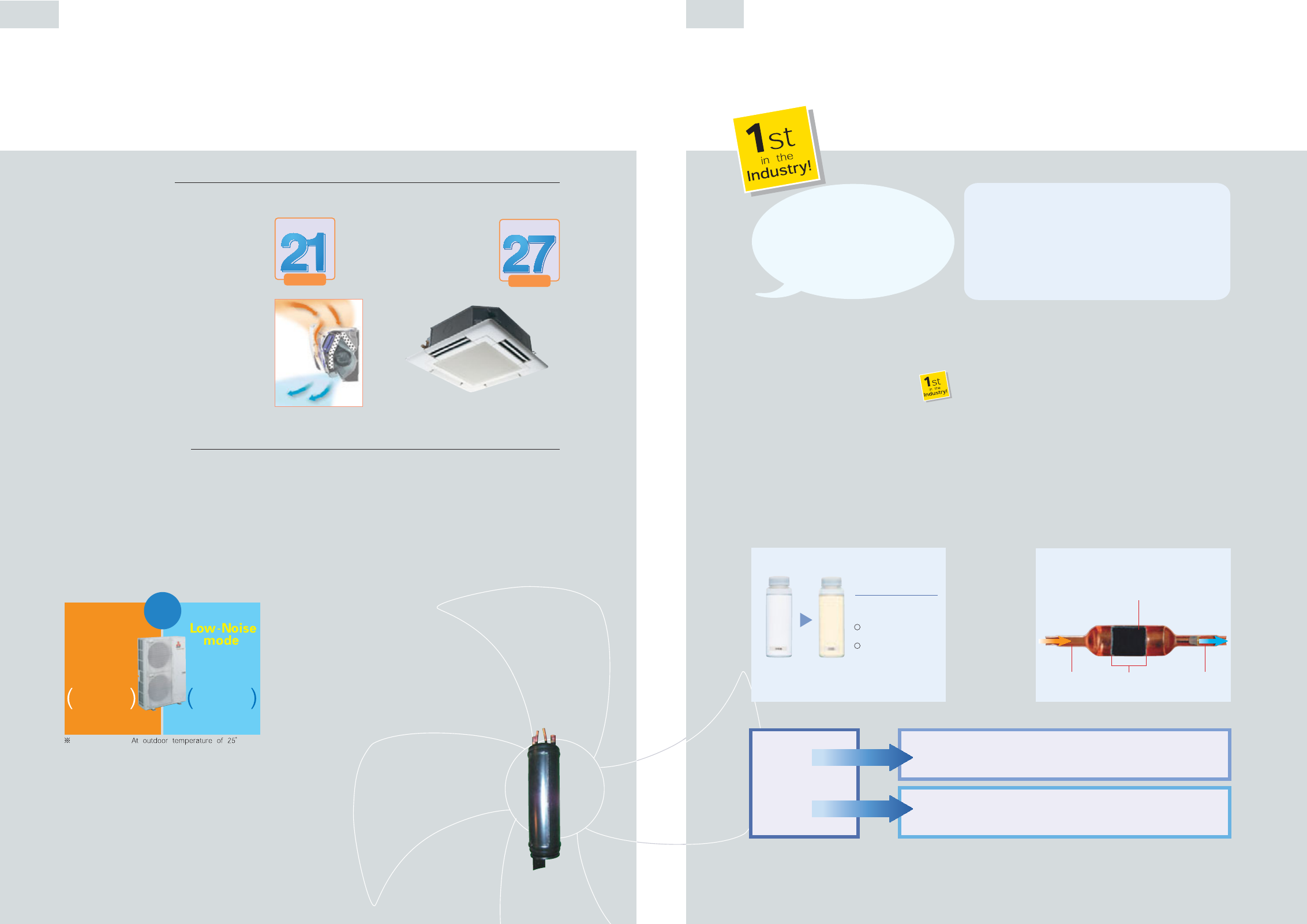

Ultra Silent Indoor Unit Operation

Noise level during normal operation is

only 21dB for the new MSZ-FA/GA25,

making it one of the quietest indoor units

in the industry. Inside the unit, the multi-

angled heat exchanger has a modified fin

shape that reduces air resistance for a

smoother, quieter airflow. The wide fan

diameter produces greater airflow at

lower fan speeds and the uneven pitch

between each fan blade helps to

eliminate annoying noise. What’s more,

the remote controlled vane significantly

decreases downward air resistance for

much lower noise levels.

Quiet 4 way Cassette

Reduced airflow resistance

and a redesigned shape of

the heat exchanger fin

make very quiet operation.

Q.

A.

In general, why is the reuse of existing

pipework not allowed for models with

R407C or R410A HFC refrigerant?

This is because existing pipework contains moisture and

chloride residue that, when mixed with compressor's

ester oil, can result in a chemical reaction. Additionally,

refrigerant oil sludge and corrosion within the

compressor can clog up the refrigerant circuit.

Our Inverter-driven models are the first in

the industry to use hard alkyl benzene

(HAB) oil — a unique refrigerant oil that

degrades very slowly — for refrigeration.

Employing our exclusive cleaning-free

technologies such as a specially developed

high-efficiency oil separator and optimum

distribution of heat exchangers to prevent

oil stagnation, we have made it possible

to reuse previously installed pipeworks.

MSZ Series, MXZ Series (except for MXZ-8A140VA),

PUHZ-RP35/50/60/71 Features

New HAB Refrigerant Oil

The refrigerant oil (ester oil) used for the

10.0~25.0kw models will degrade when

mixed with chemicals such as chloride

found in existing pipes. To prevent oil

degradation and make it possible to reuse

existing pipes, Mitsubishi Electric has

developed an exclusive replacement filter

that uses activated charcoal to soak up

chlorides.

PUHZ-RP100/125/140/200/250 Features

Exclusive Replacement Filter

Mitsubishi Electric’s Cleaning-Free Technology

Replacement filter (conceptual diagram)

Refrigerant circuit lasts longer with less deterioration

using the new HAB refrigerant oil*

*Data taken from our lab: Test results equivalent to 10 years worth of use

Characteristics of the new

refrigerant oil

Colour of the oil

at initial stage

Colour of the oil at

10 years after use

Name: HAB Oil

Oil characteristics:

Difficult to dissolve in

the refrigerant.

High chemical and heat

stability, uniform quality,

high fluidity and viscosity.

Activated carbon

(absorbs chlorine and other chemicals)

Filter

Outlet

RefrigerantRefrigerant

Inlet

1

2

Silent Operation Technology

Cleaning-Free, Pipe Reuse Technology

DAY

50dB

in

cooling mode

NIGHT

47dB

*

in

cooling mode

( PUHZ and Power Multi )

Indoor Unit

Outdoor Unit

dB

Only

PLA-RP35AA

• Reduces installation time for less disruption of business.

• Saves installation costs.

• Installation time is reduced significantly, so you have more time to do other work.

• Not necessary to find proper pipings for R410A refrigerant.

• Time-consuming pipe cleaning is not necessary, even if the owner wants to

reuse the existing pipework.

Advantages

For tenants /owner

For installer

Refrigerant condensed in the condenser

of the outdoor unit is heat-exchanged

with the low temperature refrigerant

inside the accumulator, and subcooled.

Doing this way, refrigerant will reach the

LEV (Linear Expansion Valve) while

keeping the optimum state even when

the branch box is installed far from the

outdoor unit.

This has enabled to reduce the

refrigerant noise at the LEV

section, and has optimized the

refrigerant distribution to each

indoor unit, proving great

effectiveness in the installation

environment with a large piping

loss (pressure loss) due to a long

piping length or a large height

difference.

Reduction of

Refrigerant Noise

PUHZ

-

RP125/140

:

9

10