- 52 -

3.Duct Work

(1) All series units are equipped with horizontal

supply and return air openings. Duct connection to

the unit should be made with duct flanges and

secured directly to the air openings with flexible

duct connectors to avoid normal noise transmission.

(2) For vertical air supply, a field supply plenum should

be used.

The figure below shows the recommended method

for duct connection.

(3) To prevent air leakage, all duct seams should be

taped.

Ducts run in air spaces that are not air-conditioned

must be insulated and provided with a vapor barrier.

Ducts exposed to the outside must be

weatherproofed. For quiet operation, we

recommend that the insulation on the supply duct

be placed inside, lining the duct.

(4) Where ducts from the outside enter a building, the

duct openings in the building should be sealed with

weather stripping to prevent rain, duct, sand,etc.

from entering the building.

(5) Correctly sized filters must be fitted and there is no

provision within the unit, however the filters may be

installed in the return air.

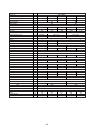

4.Drain piping

(1) A 1 FPT condensate drain fitting is provided. The

drain pipe can be led out at the right or left side.

Under standard specifications, it is led out at the left

side and the right side is covered.

(2) The drain pipe must be provided with a trap on the

outside of the unit and also installed at an incline for

proper drainage, as shown below.

(3) To prevent condensate formation and leakage,

provide the drain pipe with insulation to safeguard

against sweating.

(4) Upon completion of the piping work, check that there

is no leakage and that the water drains off properly.

Duct connection with a vertical air plenum

Insulation

Singleduct

divider

Duct

Duct

Roof line

Roof curb

Roof curb

Plenum

divider

Vertical air

plenum

PRH unit

B

AC

Drain trap for condensate

Note:ESP=External Static Pressure

The drain pipe

should extend

below this level.

Drain piping

Drain trap

A

>

70mm

B

>

2C

C

>

2XE.S.P

=

=

=