Page 28

506636−01

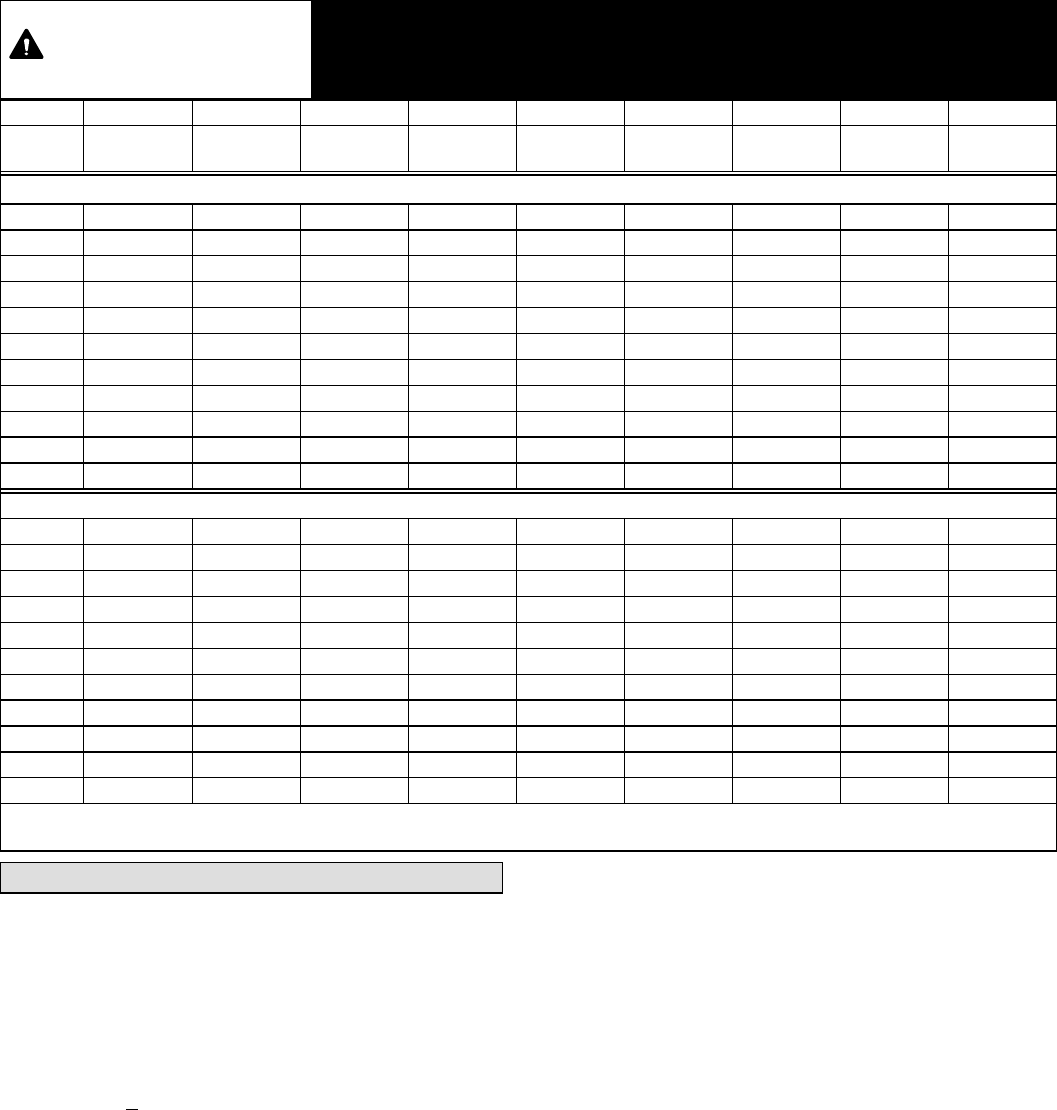

Table 4. Normal Operating Pressures (Liquid +10 and Suction +5 psig)

IMPORTANT

Use this table to perform maintenance checks; it is not a procedure for charging the

system. Minor variations in these pressures may be due to differences in installations.

Significant deviations could mean that the system is not properly charged or that a

problem exists with some component in the system.

Model −018 −024 −030 −036 −041 −042 −047 −048 −060

**Temp.

5F (5C)

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Liquid /

Suction

Expansion Valve (TXV)

65 (18) 230 / 138 225 / 135 226 / 129 238 / 132 233 / 142 236 / 138 233 / 139 238 / 136 239 / 133

70 (21) 244 / 139 242 / 137 241 / 131 254 / 135 239 / 142 253 / 140 252 / 140 256 / 138 258 / 135

75 (24) 265 / 140 260 / 138 259 / 134 273 / 138 256 / 143 273 / 141 272 / 141 277 / 139 278 / 136

80 (27) 286 / 140 282 / 140 281 / 138 293 / 140 278 / 144 296 / 142 294 / 142 299 / 140 300 / 137

85 (29) 307 / 142 304 / 141 301 / 140 316 / 142 299 / 145 318 / 143 315 / 142 320 / 139 323 / 138

90 (32) 330 / 143 326 / 142 324 / 141 340 / 143 321 / 145 341 / 144 338 / 144 343 / 140 346 / 139

95 (35) 351 / 144 351 / 142 348 / 142 366 / 144 343 / 146 366 / 146 361 / 144 369 / 141 370 / 140

100 (38) 380 / 144 376 / 144 372 / 143 392 / 145 366 / 147 392 / 147 387 / 144 395 / 142 396 / 142

105 (41) 407 / 145 403 / 145 399 / 144 420 / 147 389 / 148 417 / 148 413 / 145 422 / 144 415 / 143

110 (43) 436 / 146 433 / 145 428 / 145 449 / 148 421 / 149 445 / 149 442 / 148 450 / 146 449 / 145

115 (45) 466 / 147 463 / 147 456 / 146 480 / 149 452 / 151 475 / 151 465 / 148 481 / 148 476 / 147

Fixed Orifice (RFC)

65 (18) 232 / 124 228 / 125 229 / 128 241 / 131 228 / 131 248 / 135 232 / 125 240 / 126 244 / 125

70 (21) 248 / 127 244 / 127 243 / 129 258 / 134 245 / 135 266 / 138 249 / 129 260 / 129 263 / 128

75 (24) 267 / 131 261 / 131 261 / 132 277 / 136 263 / 138 285 / 141 268 / 133 281 / 133 281 / 131

80 (27) 286 / 135 284 / 134 284 / 135 298 / 139 284 / 141 305 / 143 286 / 136 301 / 135 303 / 134

85 (29) 307 / 138 303 / 137 305 / 138 321 / 141 306 / 144 327 / 145 312 / 140 324 / 138 324 / 136

90 (32) 328 / 141 325 / 140 327 / 140 342 / 143 327 / 146 349 / 147 332 / 142 346 / 140 347 / 139

95 (35) 351 / 143 347 / 142 349 / 142 366 / 145 348 / 148 372 / 149 357 / 144 371 / 142 370 / 141

100 (38) 375 / 146 370 / 144 372 / 144 392 / 147 372 / 149 396 / 150 379 / 146 395 / 144 394 / 143

105 (41) 400 / 148 394 / 146 396 / 146 416 / 149 395 / 151 421 / 152 406 / 149 420 / 146 418 / 145

110 (43) 426 / 150 420 / 148 422 / 148 446 / 151 424 /153 447 / 153 430 / 150 447 / 148 444 / 146

115 (46) 457 / 153 447 / 150 449 / 150 480 / 152 453 / 155 476 / 154 460 / 152 473 / 150 471 / 147

*Values shown are typical pressures; indoor unit match up, indoor air quality equipment, and indoor load will cause the pressures to vary.

**Temperature of the air entering the outside coil.

System Operation

UNIT COMPONENTS

High Pressure Switch (S4)

XC14 units are equipped with a high-pressure switch that

is located in the liquid line of the compressor as illustrated

in Unit Dimensions on page 2. The switch is a Single Pole,

Single Throw (SPST), manual−reset switch with red cap

that is normally closed and removes power from the

compressor when discharge pressure rises above factory

setting at 590 + 10 psi.

Thermal Protection Switch (S5) Ċ Discharge Line

Mounted

This unit is equipped with a discharge line mounted

temperature switch that prevents compressor damage

due to loss of charge. The switch is located on the

discharge line (see figure 1 for location). When the switch

senses a discharge line temperature of 220°F +/−5°F, it

opens to shut off compressor operation. The auto−reset

switch closes when the discharge line temperature drops

below 180°F +/−9°F and the compressor is re−energized.

This single−pole, single−throw (SPST) bi−metallic switch is

wired in series with the 24V Y input signal to control

compressor operation.

Thermal Protection Switch (S173) Ċ Compressor

Mounted

Some units are equipped with a compressor mounted

normally closed temperature switch that prevents

compressor damage due to overheating caused by

internal friction. The switch is located on top of the

compressor casing (see figure 1). This switch senses the

compressor casing temperature and opens at 239−257°F

(115°C−125°C) to shut off compressor operation. The

auto−reset switch closes when the compressor casing

temperature falls to 151−187°F (66°C−86°C), and the

compressor is re−energized. This single−pole, single−throw

(SPST) bi−metallic switch is wired in series with the 24V Y

input signal to control compressor operation.

Crankcase Thermostat (S40) (−041, −047, −048 and

−060 units only)

Compressor in the above reference units are equipped

with a 70 watt, belly band type crankcase heater. HR1

prevents liquid from accumulating in the compressor. HR1

is controlled by a thermostat located on the liquid line.