8- Honeywell VR8205 Gas Valve with ON/OFF Switch

- Move gas valve switch to ON. See figure 27.

Honeywell VR8205 Gas Valve with Control Knob -

Turn knob on gas valve counterclockwise _ to ON,

Do not force. See figure 28,

White Rodgers 36G Gas Valve - Move gas valve

switch to ON, See figure 29,

9 - Replace the upper access panel,

10- Turn on all electrical power to to the unit,

11- Set the thermostat to desired setting,

NOTE - When unit is initially started, steps 1 through 11

may need to be repeated to purge air from gas line,

12- If the appliance will not operate, follow the instructions

"Turning Off Gas to Unit" and call your service techni-

cian or gas supplier,

Turning Off Gas to Unit

1 - Set the thermostat to the lowest setting,

2 - Turn off all electrical power to the unit if service is to be

performed,

3 - Remove the upper access panel,

4 - Honeywell VR8205 Gas Valve with ON/OFF Switch

- Move gas valve switch to OFF, See figure 27.

Honeywell VR8205 Gas Valve with Control Knob -

Turn knob on gas valve clockwise clio to OFF, Do not

force, See figure 28,

White Rodgers 36G Gas Valve - Move gas valve

switch to OFF, See figure 29,

5 - Replace the upper access panel.

Heating Sequence Of Operation

1 - When thermostat calls for heat, combustion air inducer

starts,

2 - Combustion air pressure switch proves combustion air

inducer operation. Switch is factory set and requires no

adjustment,

3 - After a 15 second prepurge, the hot surface ignitor en-

ergizes,

4- After a 20 second ignitor warm-up period, the gas

valve solenoid opens,

5 - Gas is ignited, flame sensor proves the flame, and the

combustion process continues,

6 - If flame is not detected after first ignition trial, the igni-

tion control will repeat steps 3 and 4 four more times

before locking out the gas valve ("WATCHGUARD"

flame failure mode), The ignition control will then auto-

matically repeat steps 3, 4, 5, and 6 after 60 minutes,

7- To interrupt the 60-minute "WATCHGUARD" period,

move thermostat from "Heat" to "OFF" then back to

"Heat", Heating sequence then restarts at step 1.

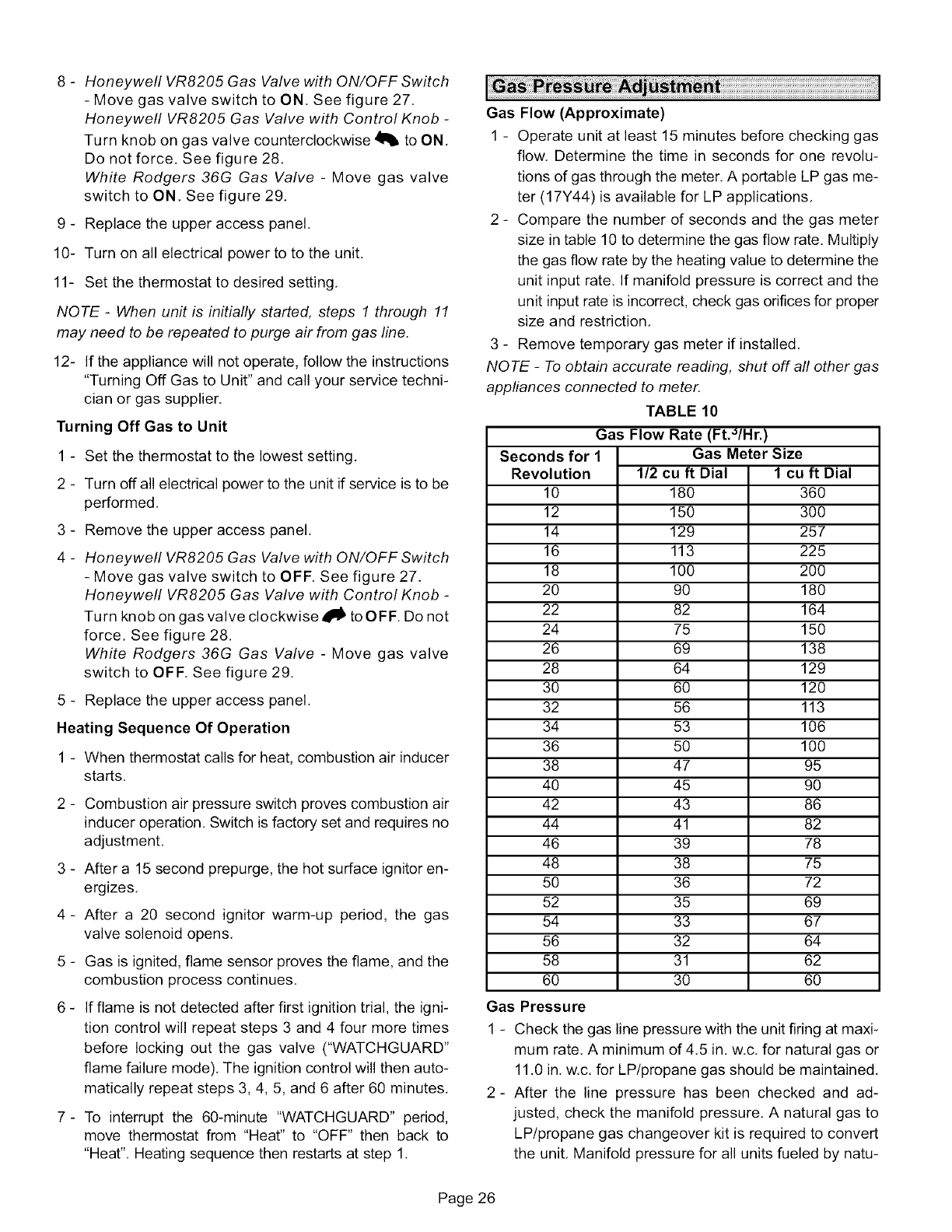

Gas Flow (Approximate)

1 - Operate unit at least 15 minutes before checking gas

flow. Determine the time in seconds for one revolu-

tions of gas through the meter, A portable LP gas me-

ter (17Y44) is available for LP applications,

2 - Compare the number of seconds and the gas meter

size in table 10 to determine the gas flow rate. Multiply

the gas flow rate by the heating value to determine the

unit input rate, If manifold pressure is correct and the

unit input rate is incorrect, check gas orifices for proper

size and restriction,

3 - Remove temporary gas meter if installed,

NOTE - To obtain accurate reading, shut off all other gas

appliances connected to meter,

TABLE 10

Gas Flow Rate (Ft.'_/Hr.)

Seconds for 1

Revolution

10

12

14

16

18

2O

22

24

26

28

3O

32

34

36

38

4O

42

44

46

48

5O

52

54

56

58

6O

Gas Pressure

Gas Meter Size

1/2 cu ft Dial 1 cu ft Dial

180 360

150 300

129 257

113 225

100 200

90 180

82 164

75 150

69 138

64 129

60 120

56 113

53 106

50 100

47 95

45 90

43 86

41 82

39 78

38 75

36 72

35 69

33 67

32 64

31 62

30 60

1 - Check the gas line pressure with the unit firing at maxi-

mum rate. A minimum of 4.5 in, w.c. for natural gas or

11,0 in, w,c, for LP/propane gas should be maintained,

2- After the line pressure has been checked and ad-

justed, check the manifold pressure. A natural gas to

LP/propane gas changeover kit is required to convert

the unit, Manifold pressure for all units fueled by natu-

Page 26