Resizethecommonventingsystemtotheminimum

ventpipesizedeterminedbyusingtheappropriate

tablesinappendixG.(Thesearein thecurrentstan-

dardsoftheNationalFuelGasCodeANSIZ223.1in

theUSA,andtheappropriateCategory1NaturalGas

andPropaneappliancesventingsizingtablesinthe

currentstandardsof theCSAB149NaturalGasand

PropaneInstallationCodesinCanada.)

A,CAUTION

3 - The gas piping must not run in or through air ducts,

clothes chutes, gas vents or chimneys, dumb waiters,

or elevator shafts.

4 - The piping should be sloped 1/4 inch (6.4 mm) per 15

feet (4,57 m) upward toward the meter from the fur-

nace. The piping must be supported at proper intervals

[every 8 to 10 feet (2.44 to 3.01 m)] with suitable hang-

ers or straps, Install a drip leg inside vertical pipe runs

to the unit,

5 - In some localities, codes may require the installation of

a manual main shut-off valve and union (furnished by

the installer) external to the unit, The union must be of

the ground joint type,

A, IMPORTANT

Gas Supply

1 - This unit is shipped standard for left or right side instal-

lation of gas piping (or top entry in horizontal applica-

tions). Connect the gas supply to the piping assembly.

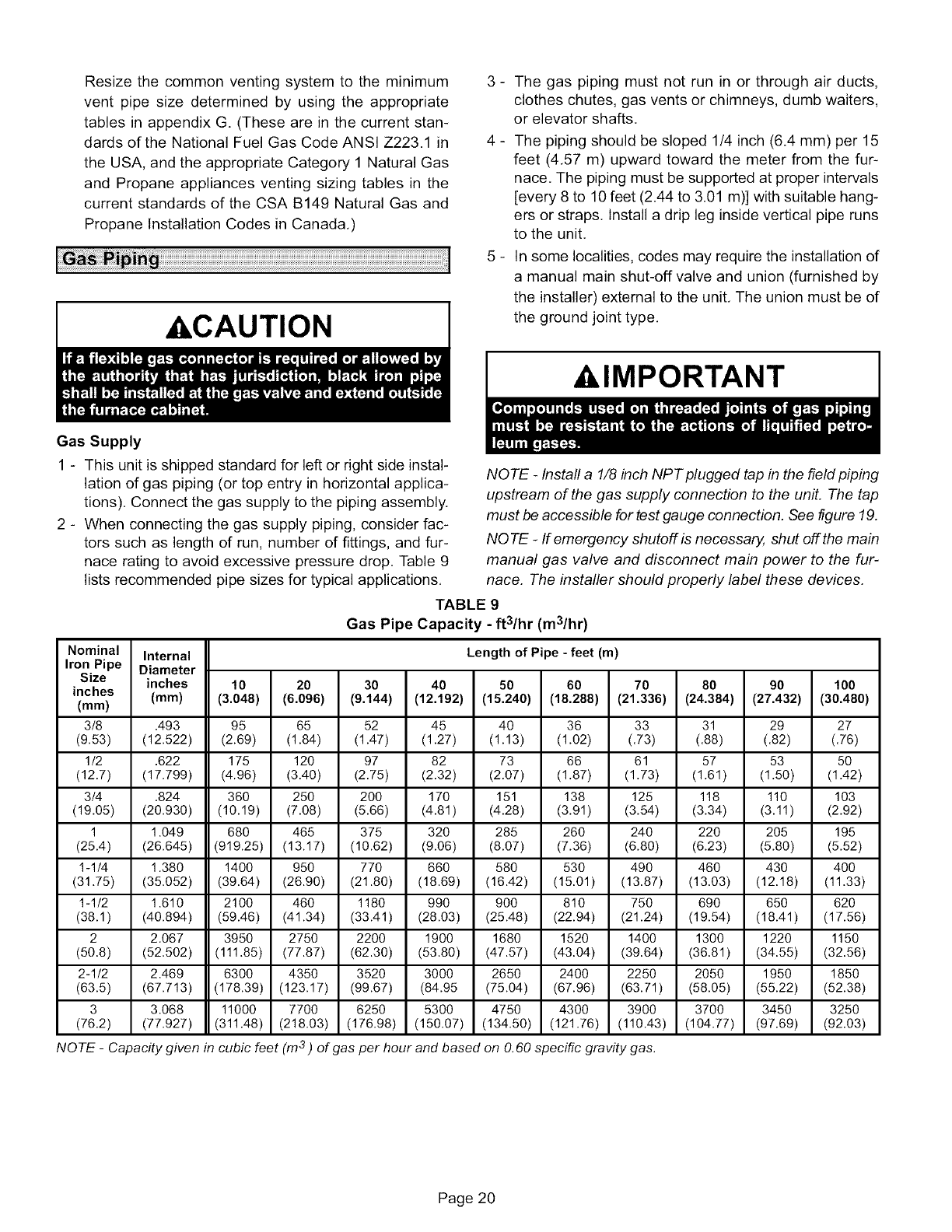

2 - When connecting the gas supply piping, consider fac-

tors such as length of run, number of fittings, and fur-

nace rating to avoid excessive pressure drop. Table 9

lists recommended pipe sizes for typical applications.

NOTE - Install a 1/8 inch NPT plugged tap in the field piping

upstream of the gas supply connection to the unit. The tap

must be accessible for test gauge connection. See figure 19.

NQ TE - If emergency shutoff is necessarj4 shut off the main

manual gas valve and disconnect main power to the fur-

nace. The installer should properly label these devices.

Nominal

IronPipe

Size

inches

(ram)

3/8

(9.53)

1/2

(12.7)

3/4

(19.05)

1

(25.4)

1-1/4

(31.75)

1-1/2

(38.1)

2

(50.8)

2-1/2

(63.5)

3

(76.2)

TABLE 9

Gas Pipe Capacity - ft3/hr (m3/hr)

Internal Length of Pipe -feet(m)

Diameter

inches 10 20 30 40 50 60 70 80 90 100

(mm) (3.048) (6.096) (9.144) (12.192) (15.240) (18.288) (21.336) (24.384) (27.432) (30.480)

.493 95 65

(12.522) (2.69) (1.84)

.622 175 120

(17.799) (4.96) (3.40)

.824 360 250

(20.930) (10.19) (7.08)

1.049 680 465

(26.645) (919.25) (13.17)

1.380 1400 950

(35.052) (39.64) (26.90)

1.610 2100 460

(40.894) (59.46) (41.34)

2.067 3950 2750

(52.502) (111.85) (77.87)

2.469 6300 4350

(67.713) (178.39) (123.17)

3.068 11000 7700

(77.927) (311.48) (218.03)

52

(1.47)

97

(2.75)

2OO

(5.66)

375

(10.62)

77O

(21.80)

1180

(33.41)

2200

(62.30)

3520

(99.67)

6250

(176.98)

45

(1.27)

82

(2.32)

170

(4.81)

32O

(9.06)

66O

(18.69)

990

(28.03)

1900

(53.80)

3000

(84.95

5300

(150.07)

NOTE - Capacity given in cubic feet (In 3) of gas per hour and based

40

(1.13)

73

(2.07)

151

(4.28)

285

(8.07)

580

(16.42)

9OO

(25.48)

1680

(47.57)

2650

(75.04)

4750

(134.50)

36

(1.02)

66

(1.87)

138

(3.91)

26O

(7.36)

53O

(15.Ol)

81o

(22.94)

1520

(43.04)

2400

(67.96)

4300

(121.76)

33

(.73)

61

(1.73)

125

(3.54)

24O

(6.80)

490

(13.87)

75O

(21.24)

1400

(39.64)

2250

(63.71)

3900

(110.43)

31

(.88)

57

(1.61)

118

(3.34)

22O

(6.23)

46O

(13.03)

690

(19.54)

1300

(36.81)

2050

(58.05)

3700

(104.77)

29

(.82)

53

(1.50)

11o

(3.11)

2O5

(5.80)

430

(12.18)

65O

(18.41)

1220

(34.55)

1950

(55.22)

3450

(97.69)

on O.60 specific gravity gas.

27

(.76)

5O

(1.42)

103

(2.92)

195

(5.52)

400

(11.33)

62O

(17.56)

1150

(32.56)

1850

(52.38)

3250

(92.03)

Page 20