Page 11

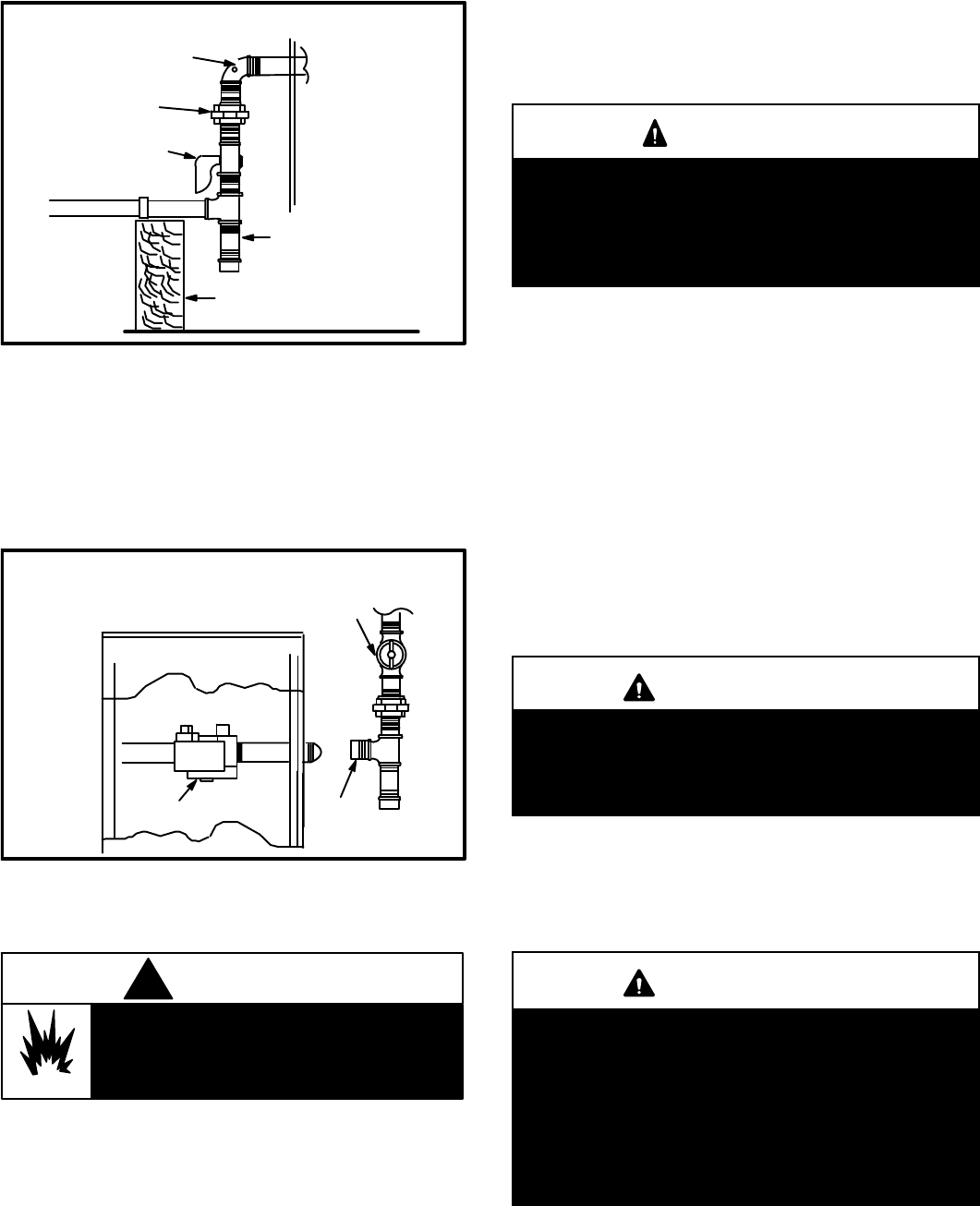

Figure 8

unit

ground joint

union

field provided

1/8 in. pressure tap

manual main

shut−off valve

drip

leg

gas piping

support

Drip Leg Installation

Pressure Test Gas Piping

When pressure testing gas lines, the gas valve must be

disconnected and isolated. Gas valve can be damaged if

subjected to more than 0.5 psig (14 inch w.c.). See figure 9.

If test pressure is equal to or less than 0.5 psig (14 inch

w.c.) shutoff the manual main shut-off valve before

pressure testing to isolate unit from gas supply system.

gas valve

cap

Manual Main Shut−off Valve Will Not Hold Test

Pressures in Excess of 0.5 PSIG (14 in. w.c.)

Figure 9

unit

Isolate Gas Valve To Pressure Test

NOTE − Codes may require that manual main shut off valve

and union (furnished by installer) be installed in gas line

external to unit. Union must be of the ground joint type.

Danger of explosion. Can cause injury or

product or property damage. Do not use

matches, candles, flame or other sources

of ignition to check for leaks.

WARNING

!

After gas piping is complete, carefully check all piping

connections (factory and field) for gas leaks. Use soap

solution or other preferred means.

NOTE − In case of emergency shutdown, shut off main

manual gas valve and disconnect main power to unit.

These devices should be properly labeled by installer.

The heating value of the gas may differ with locality. The

value should be checked with the local gas utility.

NOTE − There may be a local gas utility requirement

specifying a minimum diameter for gas piping. All units

require a 1/2 inch pipe connection at the gas valve.

Gas piping recommendations:

CAUTION

If a flexible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe

shall be installed at the gas valve and must extend

outside the cabinet. The flexible connector can then

be added between the black iron pipe and the gas

supply line.

1 − A drip leg and a ground joint union must be installed in

the gas piping.

A ground joint union is recommended by the

manifold/valve.

2 − When required by local codes, a manual shut-off valve

may have to be installed outside of the unit.

3 − Use pipe thread sealing compound resistant to

propane gas sparingly on male threads.

4 − The gas supply should be a separate line and installed

in accordance with all safety codes. After the gas

connections have been completed, open the main

shut-off valve admitting normal gas pressure to the

mains. Check all joints for leaks with soap solution or

other material suitable for the purpose.

CAUTION

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly af-

ter leak test has been completed. Do not use

matches, candles, flame or other sources of ignition

to check for gas leaks.

5 − The unit and its individual manual shut-off valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3.48kPa).

IMPORTANT

The unit must be isolated from the gas supply piping

system by closing its individual manual shut−off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig. See figure 9.

The unit and its individual shut−off valve must be dis-

connected from the gas supply piping system during

any pressure testing of the system at test pressures

greater than 1/2 psig.

6 − A 1/8 inch N.P.T. plugged tapping, accessible for test

gage connections, must be installed immediately

upstream of the gas supply connection to the furnace.