9

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

WARNING

Failure to position the parts in

accordance with these diagrams

or failure to use only parts specifi-

cally approved with this appliance

may result in property damage or

personal injury.

AVERTISSEMENT

Risque de dommages ou de

blessures si les pièces ne sont

pas installées conformément à

ces schémas et ou si des pièces

autres que celles spécifiquement

approuvées avec cet appareil sont

utilisées.

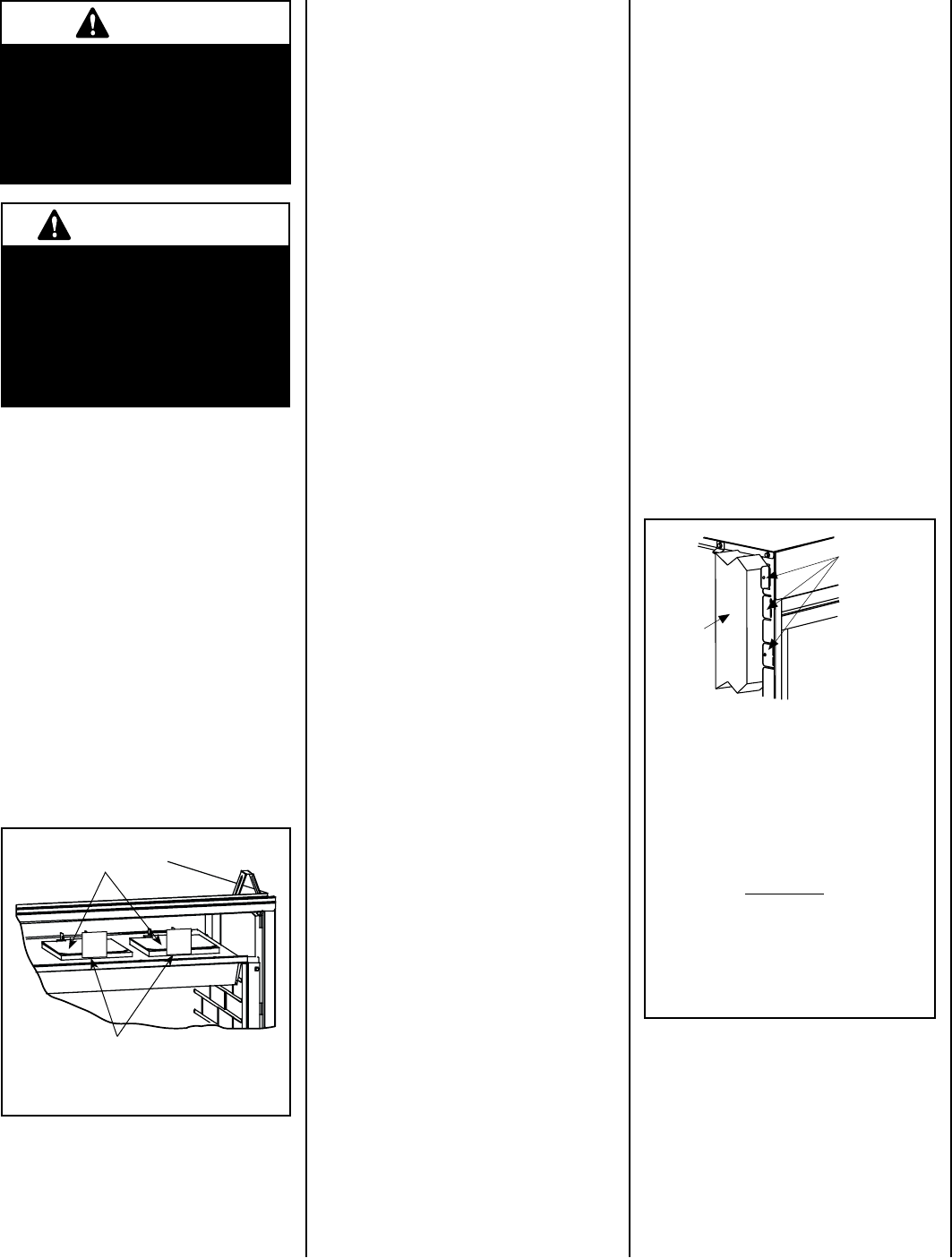

Figure 11

REMOVE

CARDBOARD

BEFORE USING

Pressure Relief

Plates

Remove Cardboard Before

Using Appliance

REMOVE

CARDBOARD

BEFORE USING

DETAILED INSTALLATION STEPS

The appliance is shipped with all gas controls

and components installed and pre-wired.

1. Remove the shipping carton. Remove the

shipping pad, exposing the front glass

door.

2. Open the two latches (located under the fire-

box floor) securing the glass door. Remove

the door by tilting it outward at the bottom

and lifting it up. Set the door aside protecting

it from inadvertent damage. See Removing

and Installing Glass Doors on Page 32.

3. Remove the top louvered panel and locate

the pressure relief plates (see Figure 11).

4. Lift the pressure relief plates and remove

the cardboard from beneath each plate (be

careful not to damage the white gasket).

Figure 12 - Nailing Flanges

Note: The nailing flanges, combustible members

and screw heads located in areas directly adjacent

to the nailing flanges, are EXEMPT from the 1/2”

clearance to combustible requirements for the

firebox outer wrapper. Combustible framing may be

in

direct contact with the nailing flanges and may

be located closer than 1/2” from screw heads and

the firebox wrapper in areas adjacent to the nailing

flanges. Frame the opening to the exact dimensions

specified in the framing details of this manual.

Nailing Flanges Are

Provided At All Four

Corners At 5/8”, 1/2”

And Flush Settings

Side

Framing

Unit

Nailing Flange

Left Side Front Corner of Fireplace Shown

(Right Side Requirements the Same)

Unit Being Secured By Its Nailing Flanges

To The Framing

Step 1. FRAMING

Frame these appliances as illustrated in Figures

13 and 14 on Pages 10 and 11 (Figure 14

applies to corner framing installations only).

All framing details must allow for a minimum

clearance to combustible framing members as

shown in Table 6 on Page 8.

If the appliance is to be elevated above floor level,

a solid continuous platform must be constructed

below the appliance.

Headers may be in direct contact with the appli-

ance top spacers when they are bent up vertically

maintaining the 3" clearance to the fireplace top,

but must not be supported by them or notched

to fit around them. All construction above the

appliance must be self-supporting. DO NOT use

the appliance for structural support.

The fireplace should be secured to the side

framing members using the unit's nailing

flanges - one top and bottom on each side of

the fireplace front. See Figure 12. Use 8d nails

or their equivalent.

Left Side Front Corner of Fireplace Shown

(Right Side Requirements the Same)

Unit Being Secured By Its Nailing

Flanges To The Framing

NOTE: The nailing flanges, combustible mem-

bers and screw heads located in areas directly

adjacent to the nailing flanges, are EXEMPT from

for the firebox outer wrapper. Combustible fram-

ing may be in direct contact with the nailing

from screw heads and the firebox wrapper in

areas adjacent to the nailing flanges. Frame

the opening to the exact dimensions specified

in the framing details of this manual.

TYPICAL INSTALLATION SEQUENCE

The typical sequence of installation is outlined

below. However, each installation is unique

and may result in variations to the steps

described.

See the page numbers references in the follow-

ing steps for detailed procedures.

Step 1. (Page 9) Construct the appliance fram-

ing. Position the appliance within

the framing and secure with nailing

brackets. Bend up the appropriate

header spacing guides for the drywall/

finish material thickness to be used

(see Figure 49). Bend up the outer

pair for 1/2" materials and the inner

pair for 5/8" materials. Bend out the

appropriate nailing flanges for the

drywall/finish material to be used.

Nailing flanges are provided for flush

framing, 1/2 inch and 5/8 inch framing

depths (see Figure 12).

Step 2. (Page 11) Route gas supply line to

appliance location.

Step 3. (Page 12) Install the vent system and

exterior termination.

Step 4. (Page 24) Field Wiring

a. Millivolt Appliances – Install the

operating control switch (not factory

provided) and bring in electrical service

line for forced air-circulating blower

(optional equipment).

b. Electronic Appliances – Field wire

and install operating control switch.

Step 5. (Page 25) Install blower kit (optional

equipment).

Step 6. (Page 26) Make connection to gas

supply.

Step 7. (Page 27) Verifying appliance opera-

tion.

Step 8. (Page 28) Install the logs, decorative

volcanic stone and glowing embers.

Step 9. (Page 32) Removing and Installing

glass door assembly.

Step 10. (Page 32) Adjust burner to ensure

proper flame appearance.

Step 11. (Page 34) Install the hoods.

Step 12. (Page 35) Attach Safety in Operation

Warnings.