NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

23

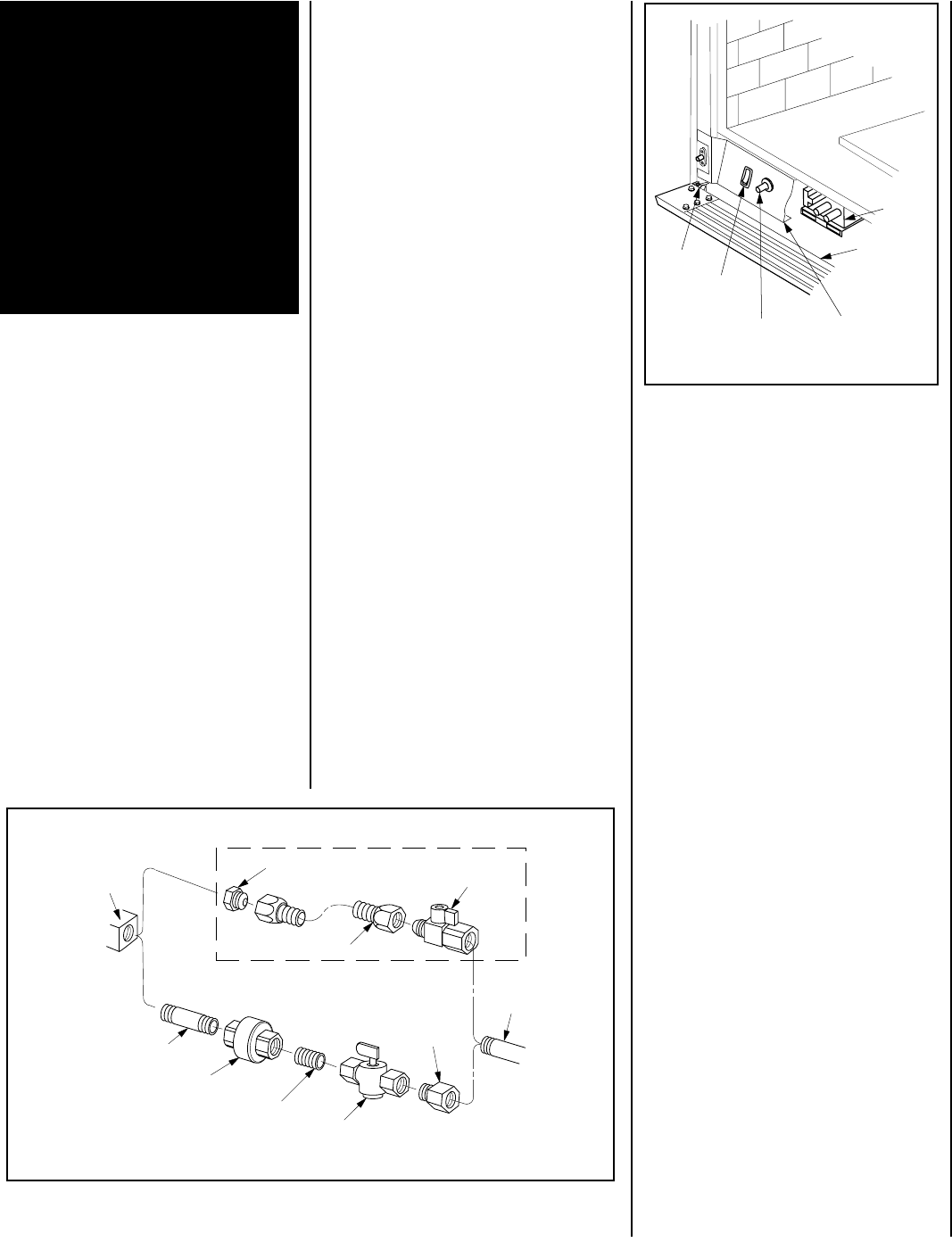

Figure 46

Piezo Ignitor

Gas

Valve

Modesty Panel

Control

Compartment

Access Panel

ON/OFF

Switch

Hinge Pin

Gas

Stub

1/2" x 3/8" Flare

Shut-Off Valve

3/8" Flex Tubing

3/8" NPT x 3/8"

Flare Fitting

3/8" Nipple

3/8" Union

3/8" Close Nipple

3/8" Shut-Off Valve

1/2" x 3/8"

Reducer

Gas

Valve

Optional Gas Flex Line Connector

Figure 45 -

GAS CONNECTION

Step 6. CONNECTING GAS LINE

Make gas line connections. All codes require a

shut-off valve mounted in the supply line.

Fig-

ure 45

illustrates two methods for connecting

the gas supply. The flex-line method is accept-

able in the U.S., however, Canadian require-

ments vary depending on locality. Installation

must be in compliance with local codes.

These appliances are equipped with a gas flex

line for use (where permitted) in connecting the

unit to the gas line. A gas flex line is provided

to aid in attaching the direct vent appliance to

the gas supply. The gas flex line can only be

used where local codes permit. See

Figure 45

for flex line description. The flex line is rated for

both natural and propane gas. A manual shut

off valve is also provided with the flex line.

The gas control valve is located in the lower

control compartment.

To access the valve open the lower control

compartment door (

see Figure 46

) by push-

ing in the right top corner of the door. (The

door is hinged at the bottom.) Remove the

bottom compartment door by sliding the hinge

pin, located at the door’s left side, to the right

until it disengages from the left corner post

hole. Pull the door diagonally to the left, away

from the fireplace.

Remove the modesty panel. To remove the

modesty panel, slide the panel forward until it

contacts the cabinet bottom panel, then lift

straight up and tilt forward.

Remove the modesty panel carefully, so

that none of the wires become loose or

disconnected.

Secure all joints tightly using appropriate

tools and sealing compounds (ensure pro-

pane resistant compounds are used in pro-

pane applications).

Turn on gas supply and test for gas leaks,

using a gas leak test solution (also referred to

as bubble leak solution).

Note: Using a soapy water solution (50% dish

soap, 50% water) is an effective leak test

solution but it is not recommended, because

the soap residue that is left on the pipes/

fittings can result in corrosion over time. Never

use an open flame to check for leaks.

A. Light the appliance (refer to the lighting

instructions label in the control compartment

or in the Homeowner's Care and Operation

Instructions).

B. Brush all joints and connections with the

gas leak test solution to check for leaks. If

bubbles are formed, or gas odor is detected,

turn the gas control knob to the “OFF” posi-

tion. Either tighten or refasten the leaking

connection and retest as described above.

C. When the gas lines are tested and leak free,

be sure to rinse off the leak testing solution.

D. When the gas lines are tested and leak free,

observe the individual tongues of flame on the

burner. Make sure all ports are open and

producing flame evenly across the burner. If

any ports are blocked, or partially blocked,

clean out the ports.

The millivolt control valve has a 3/8"

(10 mm) NPT thread inlet port. The electronic

control valve has a 1/2" (13 mm) NPT thread inlet

port and is fitted with a 1/2" x 3/8" (13 mm x

10 mm) NPT fitting.

Step 5. WIRING - OPTIONAL FORCED AIR

BLOWER KIT

FBK-100 and FBK-200 Kits

(See Figure 43 on page 22)

-

An electrical outlet box is provided for the instal-

lation of the FBK-100, FBK-200 forced air blower

kits. Electrical power must be provided to this

box to operate these blowers. Install the blower

kits according to the installation instructions

provided with the kits.

FBK-250 Blower Kit

(See Figure 44 on page 22)-

An electrical outlet box is provided for the instal-

lation of the FBK-250 forced air blower kit.

Electrical power must be provided to this box to

operate these blowers. Install the blower kit

according to the installation instructions pro-

vided with the kit.

WARNING: ELECTRONIC MODELS OF

THESE APPLIANCES ARE EQUIPPED

WITH A THREE-PRONG (GROUNDING)

PLUG UTILIZED IN CONNECTING THE

ELECTRONIC COMPONENTS TO THE

JUNCTION BOX IN THE LOWER COM-

PARTMENT. THIS GROUNDING PLUG

PROVIDES PROTECTION AGAINST

SHOCK HAZARD AND SHOULD BE

PLUGGED DIRECTLY INTO THE PROP-

ERLY GROUNDED THREE-PRONG RE-

CEPTACLE. DO NOT CUT OR REMOVE

THE GROUNDING PRONG FROM THE

PLUG.