7

Installation should be done by a qualified service person.

Before connecting the appliance, turn off all gas appliances.

Close the main gas valve a

t the gas meter or LP tank. Make

certain there is good ventilation where the installation will be

made.

Installation should comply with all applicable building

codes and ANSI Z223.1, latest edition. Use PLP gas resistant

pipe compound to seal threaded joints.

An installer supplied,

design certified gas pressure

regulator must be installed to bring the gas supply pressure

down to 14" w.c. for LP gas or 11" for natural gas.

WARNING: Never connect an unregulated gas line to the

heater.

IMPORTANT: Check gas line pressure before connecting heater

to gas line. Gas line pressure must not be higher higher than

14" w.c. for LP gas or 11" for natural gas.

NOTE: The gas line connection can be made with 3/8”black or

steel pipe. Internally tinned copper tubing may be used in cer-

tain areas. Check your local codes. Use pipe of large enough

diameter to allow proper gas volume to heater. If pipe is too

small, undue pressure loss will occur.

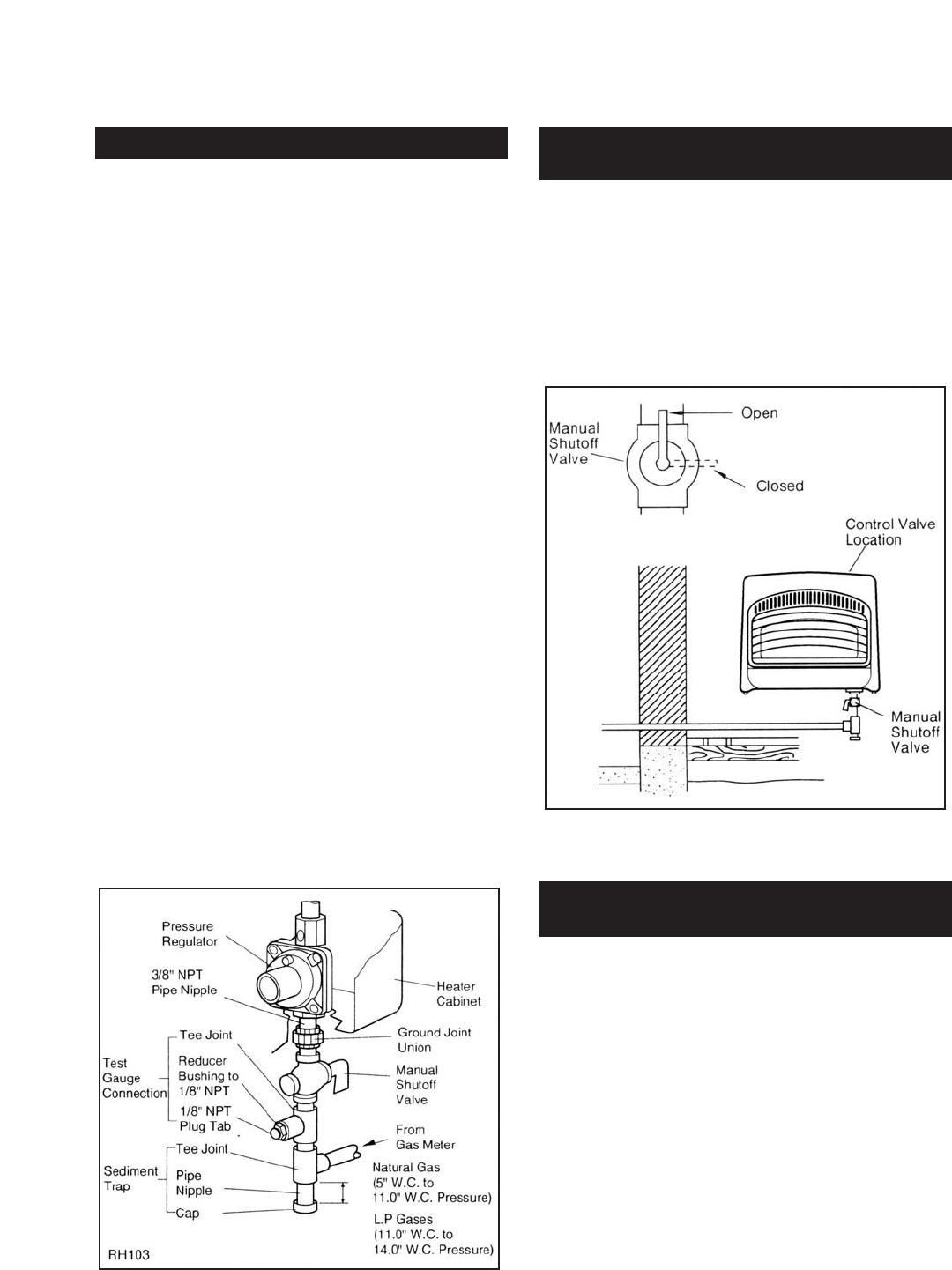

CAUTION: Use pipe joint sealant that is resistant to liquefied

petroleum gases. Install sediment trap in supply as shown in

Figure 6.

Locate sediment trap where it is within reach for cleaning.

Locate sediment trap where matter is not likely to freeze. A

sediment trap prevents moisture and contaminant's from going

into the heater controls. If the sediment trap is not installed or is

installed wrong, the heater may not operate properly.

Test for gas leaks with a mild soap and water solution. Apply

water/soap solution with brush only - do not over apply.

NEVER test with an open flame.

CONNECT TO GAS SUPPLY

Fig. 6 Gas line connection

PRESSURE TEST GAS SUPPLY

PIPING SYSTEM

The a

ppliance and its individual shut off (control) valve must

be disconnected from the gas supply piping system during any

pressure testing of the system at test pressure in excess of

1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply piping

system by closing the individual manual shut-off valve (fig. 7)

during any pressure testing of the gas supply system at test

pressure equal to or less than 1/2 psi (3.5 kPa).

Fig. 7 Manual shut-off valve location.

LEAK TESTING HEATER

GAS CONNECTION

1. Make sure control knob of heater is in the OFF position.

2. Open manual shut-off valve.

3. Open main gas valve located near gas meter.

4. check all joints from manual gas valve up to control valve

and including the manifold assembly. Apply the soap solution

around the connections, valve and tubing. Soap bubbles will

appear where a leak is present.

5. If a leak is present, immediately turn off gas supply, tighten

any leaky fittings, turn gas on and recheck.

6. To check burner and safety valve, the burner must be lit. (See

Operating Instructions) Check the rest of the connections for

leaks.

7. Turn off the heater prior to making any gas connection

repairs.