SYSTEM PIPING

I. When the installation of the boiler is for a new heating system, first instal! all of the radiation units

(panels, radiators, baseboard, or tubing) and the supply and return mains. After all heating system piping

and components have been installed, make final connection of the system piping to the boiler. It is

recommended to mount the circulating pump on the supply side piping, such that it pumps away from the

expansion tank. Refer to the figures on the next pages.

2. A hot water boiler installed above radiation level must be equipped with a low water cut off device. A

periodic inspection is necessary, as is flushing of float type devices, per low water cut off manufacturers

specific instructions.

.

The packaged boiler unit is set up with 1-1/4" NPT supply and return piping from the front of the boiler.

The boiler supply and return piping can be moved to the rear of the boiler. The boiler should not be piped

return line to the front, supply line to the rear, or vice versa, as this will cause the boiler water to short

circuit the heat exchanger. Piping connections may require additional fittings and parts.

,

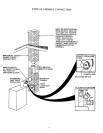

The relief valve is meant to be installed in the back side of the rear section using the 3/4" nipple and street

ell provided in the parts bag. Connect a discharge pipe of the same pipe size (3/4") to carry any water away

to a drain. Do not connect directly to a drain, but leave an air gap. No shutoffof any description shall be

placed between the safety relief valve and the boiler, or on discharge pipes between such safety valves and

the atmosphere. Installation on the safety relief valve shall conform to the ANSI/ASME Boiler and Pressure

Vessel Code, Section IV. The manufacturer is not responsible for any water damage.

5. When connecting the cold water supply to the pressure reducing valve, make sure that a clean water supply

is available. When the water supply is from a well or pump, a sand strainer should be installed at the pump.

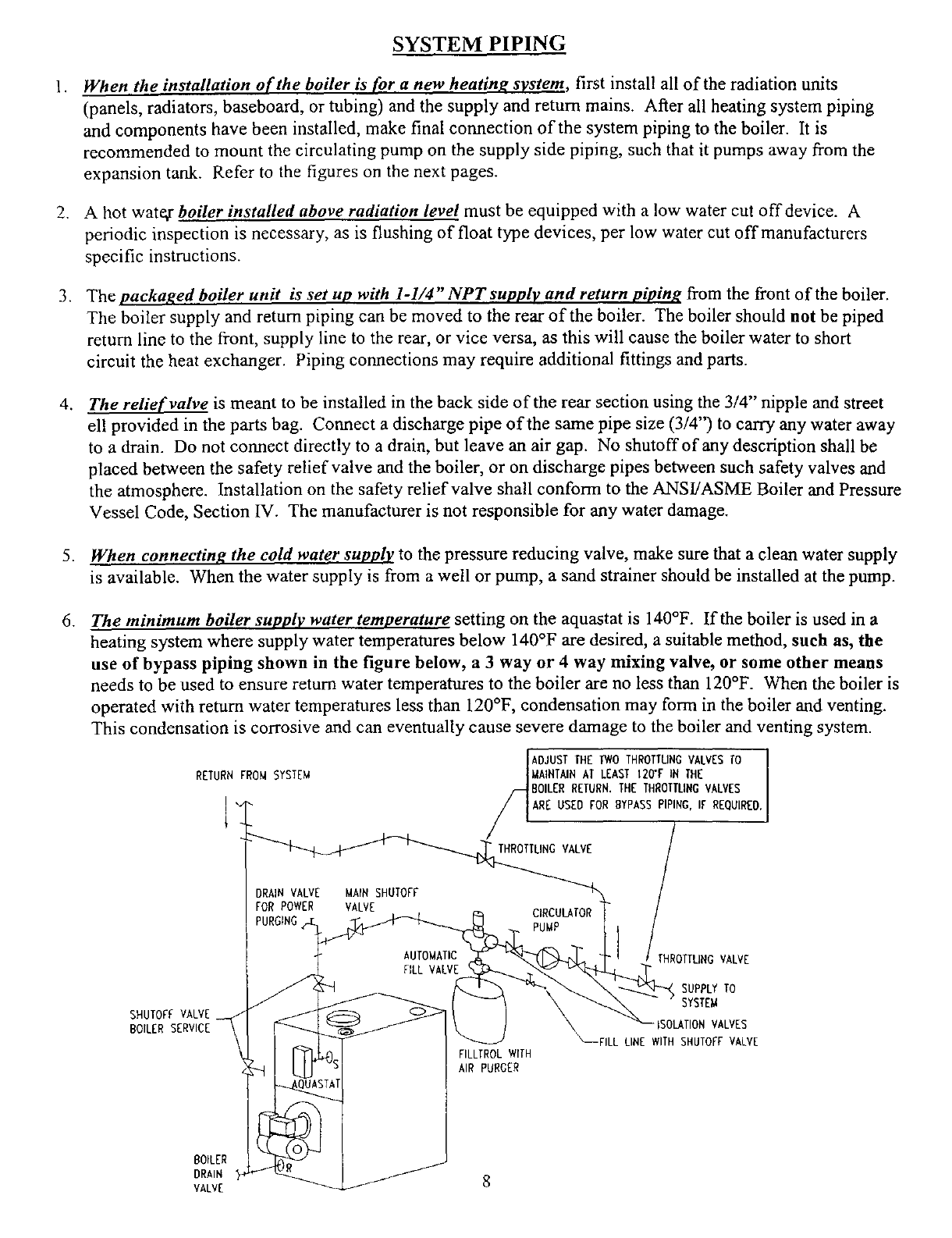

. The minimum boiler supply water temperature setting on the aquastat is 140°F. If the boiler is used in a

heating system where supply water temperatures below 140°F are desired, a suitable method, such as, the

use of bypass piping shown in the figure below, a 3 way or 4 way mixing valve, or some other means

needs to be used to ensure return water temperatures to the boiler are no less than 120°F. When the boiler is

operated with return water temperatures less than 120°F, condensation may form in the boiler and venting.

This condensation is corrosive and can eventually cause severe damage to the boiler and venting system.

RETURN FROM SYSTEM

I

DRAINVALVE

FOR POWER

PURGING

SHUTOFF VALVE

BOILERSERVICE

MAIN SHUTOFF

VALVE

AUTOMATIC

FILL VALVE

i/_ADJUST THE TWOTHROTTLINGVALVESTO

MAINTAINAT LEAST12O'F IN THE

BOILERRETURN.THE THROTTLINGVALVES

ARE USED FOR BYPASSPIPING,IF REQUIRED.

THROTTLINGVALVE l

CIRCULATOR

PUMP l

OffUNG VALVE

SUPPLY TO

SYSTEM

ISOLATIONVALVES

_FILL LINEWITH SHUTOFFVALVE

FILLTROLWITH

AIR PURGER

BOILER

DRAIN

VALVE 8