PAGE 3 OF 8PD30X-X

AIR

AND LUBE REQUIREMENTS

WARNING EXCESSIVE AIR PRESSURE. Can cause pump

damage, personal injury or property damage.

S A filter capable of filtering out particles larger than 50 microns

should be used on the air supply. In most applications there is no

lubrication required other than the ``O" ring lubricant which is apĆ

plied during assembly or repair.

S When lubricated air is necessary, supply the air lubricator with a

goodgrade of SAE 90 wt.non-detergent oil andsetthelubricator to

a rate not to exceed one drop per minute.

OPERATING INSTRUCTIONS

S Always flush the pump with a solvent compatible with the material

being pumped if the material being pumped is subject to ``setting

up" when not in use for a period of time.

S Disconnect the air supply from the pump if it is to be inactive for a

few hours.

S The outlet material volume is governed not only by the air supply

but also by the material supply available at the inlet. The material

supply tubing should not be too small or restrictive. Be sure not to

use hose which might collapse.

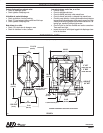

S When the diaphragm pump is used in a forced-feed (flooded inlet)

situation it is recommended that a ``Check Valve" be installed at the

air inlet.

S Secure the diaphragm pump legs to a suitable surface to insure

against damage by vibration.

MAINTENANCE

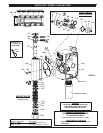

Refer to the part views and descriptions asprovided on page 4 through

7 for parts identification and Service Kit information.

S Certain ARO``SmartParts" areindicated which shouldbe available

for fast repair and reduction of down time.

S Service kits are divided to service two separate diaphragm pump

functions: 1. AIR SECTION,2. FLUID SECTION. The FLUIDSECĆ

TION is dividedfurther to match typical partMATERIAL OPTIONS.

MAINTENANCE (CONT’D)

S Provide a clean work surface to protect sensitive internal moving

parts from contamination from dirt and foreign matter during serĆ

vice disassembly and reassembly.

S Keep good records of service activity and include pump in prevenĆ

tive maintenance program.

S Before disassembling empty captured material in the outlet manĆ

ifold by turning the pump upside down to drain material from the

pump.

FLUID

SECTION DISASSEMBL

Y

1. Remove top manifold(s).

2. Remove (22) balls, (19) ``O" rings and (21) seats.

3. Remove (15) fluid caps.

NOTE: Only diaphragm models use a primary (7) diaphragm

and a backup (8) diaphragm. Refer to the auxiliary view. Fig.1

4. Remove the (6) nut, (7) or (7/8) diaphragms and (5) washer.

NOTE: Do not scratch or mar the surface of (1) diaphragm rod.

FLUID

SECTION REASSEMBL

Y

SERVICE NOTE: ARO PN 204214-T Diaphragm Assembly Tool isrecĆ

ommended for use when reassembling the pump.

S Reassemble in reverse order.

S Clean and inspect all parts. Replace worn or damaged parts with

new parts as required.

S Lubricate (1) diaphragm rod and (144) ``U" cup with Lubriplate

FML-2 Grease. (94276 grease packet is included in service kit.)

S Be certain the diaphragm assembly bottoms out on the (1) rod,

back off Teflon Diaphragm assembly far enough to align holes.

S For models with Teflon diaphragms: Item (8) Santoprene diaĆ

phragm is installed with the side marked ``AIR SIDE" towards the

pump center body. Install the (7) Diaphragm with the side

marked ``FLUID SIDE" towards the fluid cap.

S Re-check torquesettings after pump hasbeenre-startedandrun a

while.

KynarRisaregisteredtrademarkofPenwaltCorp.SGeolastRisaregisteredtrademarkofAdvancedElastomerSystems

SantopreneRisaregisteredtrademarkofMonsantoCompany,licensedtoAdvancedElastomerSystems,L.P.

PTFE

PTFE