OPERATOR’S

MANUAL

PD30X–X

RELEASED: 9–18–95

REVISED: 6–22–10

(REV.

J)

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

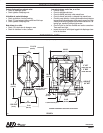

3”

DIAPHRAGM PUMP

1:1

RA

TIO (METALLIC)

READ THIS MANUAL CAREFULL

Y BEFORE INST

ALLING,

OPERA

TING OR SER

VICING THIS EQUIPMENT

.

It

is the responsibility of the employer to place this information in the hands of the operator

. Keep for future reference.

SERVICE KITS

Refer to Model Chart to match the pump material options.

637303-XX for Fluid Section Repair (see page 4). Note: This kit also

contains several air motor seals which will need to be replaced.

637302 for Air Section Repair (see page 6).

PUMP

DA

TA

Models See Model Description Chart for ``-XXX''....

Pump Type Metallic Air Operated Double Diaphragm

Material See Model Description Chart....

Weight Aluminum (wet end) 102 lbs (46.3 kgs).... ......

Cast Iron (wet end) 192.5 lbs (87.3 kgs)......

Hastelloy (wet end) 193 lbs (87.5 kgs)......

Stainless Steel (wet end) 193 lbs (87.5 kgs)..

(add 36lbs [16.3kg] forstainlesssteel airmotor section)

Maximum Air Inlet Pressure 120 p.s.i.g. (8.3 bar).........

Maximum Material Inlet Pressure 10 p.s.i.g. (.69 bar).....

Maximum Outlet Pressure 120 p.s.i.g. (8.3 bar)...........

Maximum Flow Rate (flooded inlet) 275 g.p.m. (1041 l.p.m.)......

Displacement / Cycle @ 100 p.s.i.g. 2.8 gal. (10.6 l)...

Maximum Particle Size 3/8" dia. (9.5 mm).............

Maximum Temperature Limits 200_F (93_C)........

Dimensional Data See page 8.................

Mounting Dimensions 12" x 13-1/2" (304.8 mm x 342.9 mm)....

Noise Level @ 70 psi, 50 C.P.M.À 83.0 db(A)Á.....

À Tested with 94085muffler assembly installed.

ÁThe pumpsoundpressure levelspublishedhere havebeen updated to an Equivalent

ContinuousSoundLevel(L

Aeq

)tomeettheintentofANSIS1.13-1971,CAGI-PNEUROP

S5.1 using four microphone locations.

NOTICE:AllpossibleoptionsareshowninthecharthowevercertaincomĆ

binationsmaynotberecommended,consultarepresentativeorthefactoĆ

ry if you havequestions concerning availability.

GENERAL

DESCRIPTION

The ARO Diaphragm Pump offers high volume delivery even at low air

pressure and a broad range of material compatibility options available.

Refer to the model and option chart. ARO pumps feature stall resistant

design, modular air motor / fluid sections.

Air operated double diaphragm pumps utilize a pressure differential in

the air chambers to alternately create suction and positive fluidpressure in

the fluid chambers, ball checks insure a positive flow of fluid.

Pump cycling will begin as air pressure is applied and it will continue to

pump and keep up withthe demand. It willbuild and maintain linepresĆ

sure and will stop cycling once maximum line pressure is reached (disĆ

pensing device closed) and will resume pumping as needed.

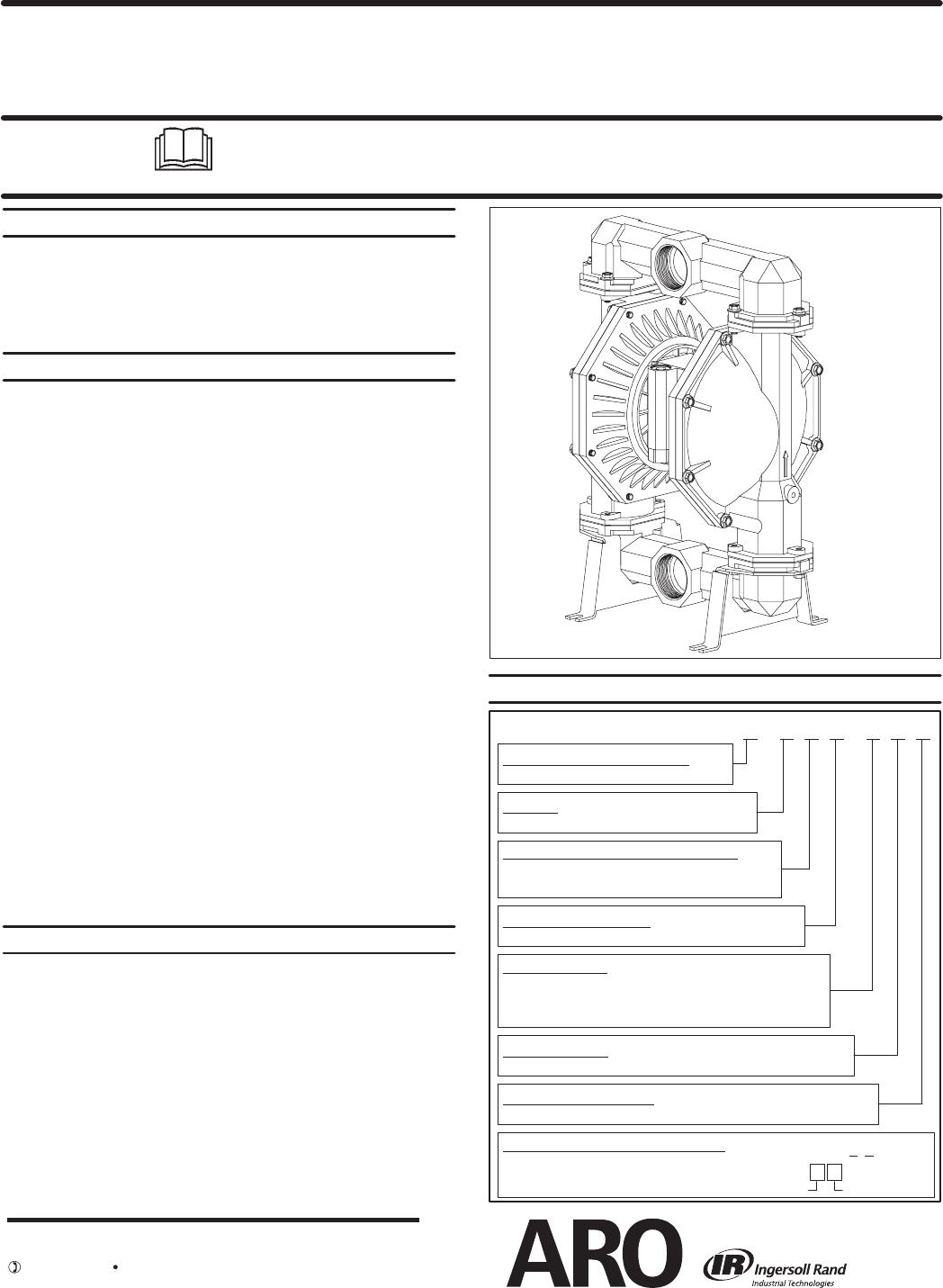

3''DIAPHRAGMPUMP

PD30X-XXX-XXX

D005

MODEL

DESCRIPTION CHART

PD30 X -X X X -X X X

PD30X- XXX -X X X

637303 - X X

DIAPHRAGMBALL

FLUIDSECTIONSERVICEKITSELECTION

EXAMPLE:MODEL # PD30A-ACS-SAA

FLUID SECTION SERVICE KIT # 637303-AA

SEATMATERIAL

A -SantopreneR K - PVDF (KynarR)

G - GeolastR S -316Stainless Steel

H - Hard 440 Stainless Steel

DIAPHRAGMMATERIAL

A -Santoprene G - Geolast T -

BALL MATERIAL

A -Santoprene G - Geolast T -

HARDWAREMATERIAL

P -PlatedSteel S -StainlessSteel

FLUID CAPS & MANIFOLDMATERIAL

A -Aluminum H -Hastelloy

C - Cast Iron S -StainlessSteel

THREAD

A - NPT B -BSP

CENTERSECTIONMATERIAL

A -Aluminum S -Stainless Steel

PTFE

PTFE

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

© 2010

www.ingersollrandproducts.com