PAGE 5 OF 8

651616-X

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS / INITIAL SETUP PROCEDURE

WARNING

STANDCLEAR. Whenraisingor loweringthe lift.

Read the warning on page 2.

TO RAISE LIFT, (THE FIRST TIME):

1. Take note of the pump /drum clearance above. Be certain the lift is

clearofanyobjectsabove.AlsorefertoOPERATINGANDSAFETY

PRECAUTIONS found on page 2.

2. Connecttheairsupply(150p.s.i./10.3barmaximum)totheairinlet.

3. Shift the control valve lever to the ‘‘UP’’ position.

4. Raisethelift highenoughtocleartheheight ofthedrum.Stop thelift

upward travel by moving the control valve lever to the (center)

‘‘NEUTRAL’’ position.

TO RAISE LIFT, (NORMAL OPERATION):

1. Adjust the follower plate air valve pressure. DO NO OVERPRES-

SURIZE THE DRUM to avoid damage.

NOTE: Air from this valve will only pass when the control lever is in

the ‘‘UP’’ position.

2. Shift the control valve lever to the ‘‘UP’’ position.

3. Raisethelift highenoughtocleartheheight ofthedrum.Stop thelift

upward travel by moving the control valve lever to the (center)

‘‘NEUTRAL’’ position.

TO CHANGE DRUMS:

NOTE: The control lever should be in the ‘‘NEUTRAL’’ position.

1. Place a new drum into position.

TO LOWER LIFT:

WARNING

PINCH HAZARD. Follower can descend quickly

causinginjury.Keephandsclearwhenaligningwithcontainer.

Read the warning on page 2.

NOTE:Be certainthefollowerplate ventplughasbeenremoved sothat

the air trapped between the follower and the material is allowed to es-

cape from this vent. Captured air between the follower plate and drum

will escape.

NOTE:The liftmay hesitatemomentarilybefore starting downward,the

air pressureinside thepost airchamber mustdecrease beforeit willbe-

gin to descend.

1. Shift the control valve leverto the ‘‘DOWN’’ positionand proceedto

lower the pump.

2. Replacetheventplugoncethematerialbeginstooozefromthevent

opening.

DISASSEMBLY

1. Remove the top cross support bar from the cylinder pistons.

2. Remove the air valve assembly from the r ight post.

The following piston removal instructions are the same for both sides.

Piston removal requires the following tools:

S Screwdriver (flat blade)

S .400” diameter rod, 12” - 18” long

S E - Ring pliers

3. Using the E - ring pliers, remove the snap ring which retains the

backup washer and upper piston ‘‘U” cup seal.

4. Locate one of the two service holes in the cap and insert the .400”

diameter rod.

5. Locate the end of the square retaining wire found 1”down from the

top of the cylinder.

6. Thebent tipofthewire protrudesslightly. Usinga screwdriver,care-

fully pryoutthe wireslightly whileusing therod to rotatethe capina

clockwise direction360_. Unwindthe wire andexpose the endwith

the 90_ bend.

7. Remove the wire from the machined hole.

8. Remove the cap from the cylinder and remove from the piston, re-

move the washer and upper seal.

9. Remove the piston assembly. Disassemble as required to replace

worn seals.

REASSEMBLY

1. Thoroughlylubricate thecylinder wall,all sealsand especiallylubri-

cate the groove where the retaining wire is located to aid in reas-

sembly.

2. Replace the cap, align the hole with the access slot. Place the 90_

bendofthe wire intothe machinedholeandsnapinplace.Usingthe

.400” diameter rod, rotate the cap clockwise and feed the retaining

wire into position.

3. Placethenew seal(withlipsdown) onthepiston,reinstallthe wash-

er, place a sleeve over the piston rod to help ‘‘seat” the upper seal.

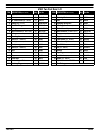

PRESSURE

REGULATOR

FOLLOWER PLATE

AIR SUPPLY VALVE

CONTROL

LEVER

GAUGE

AIR CONTROLS

FIGURE 4

OFF

ON