PN 97999-30

Page4of4 650453-X

SPECIAL INSTRUCTIONS

_Use flats on pumpbodyfor holdinginvice toremovetubes.

_ Be careful not to deform suction tube while removing.

_ Do not mar finish on plunger.

NOTE: All threads are right hand.

1. Loosen (2) nutand use strap wrench or pipewrench to unscrew (3)

spacer tube from air motor base.

2. Pull lower pump end from air motor until (F) pin is exposed.

3. Use retaining ring pliersand remove (G) retaining ring from (F)pin.

Remove (F) pin.

4. Pull lower pump end from air motor.

5. Pump reassembly is done in reverse order.

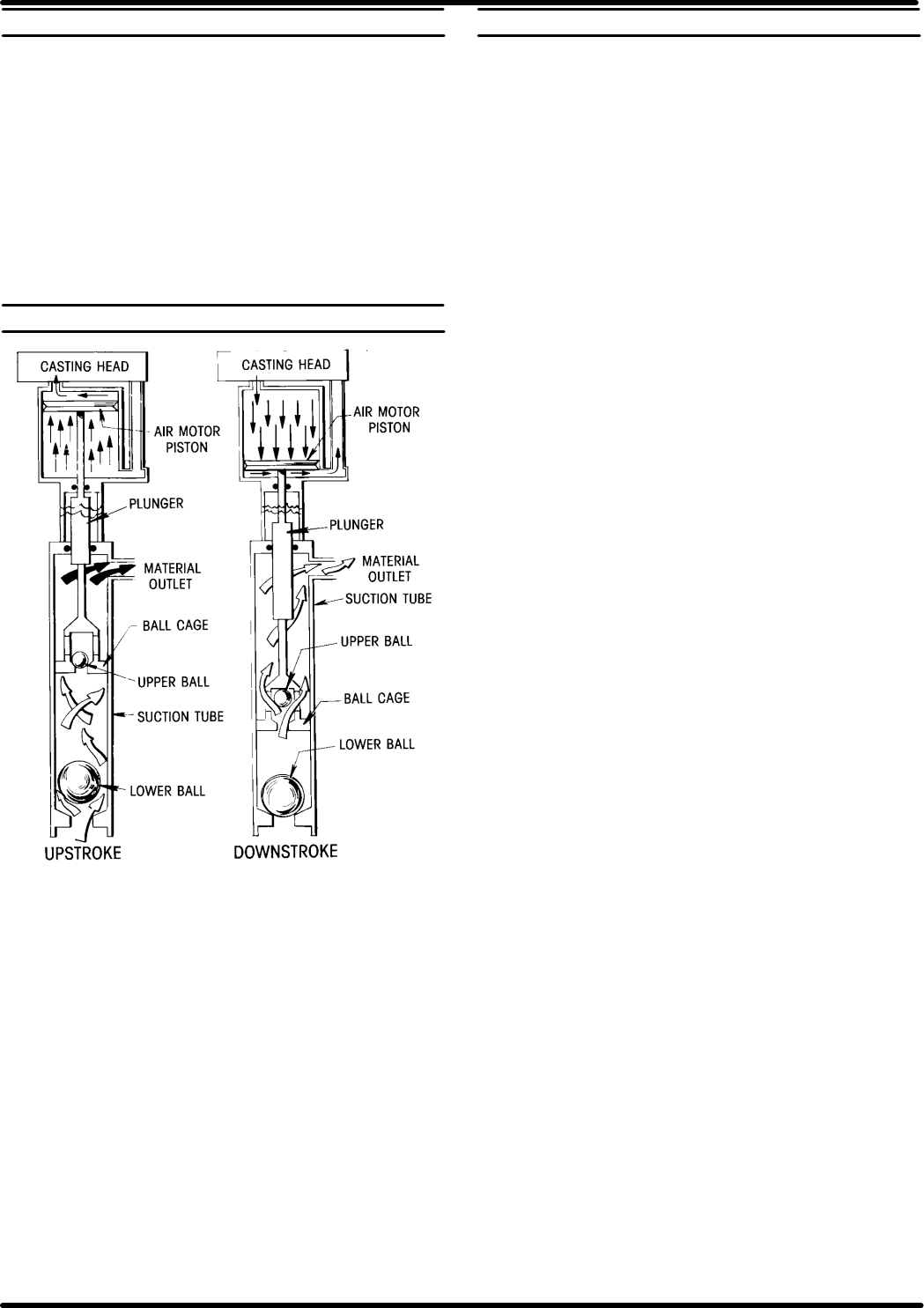

THEORY OF OPERATION

UPSTROKE

AIR MOTOR:

• Compressed air below air motor piston forces it up.

• Air above piston is exhausted.

LOWER PUMP END:

• Plunger moves upward in the suction tube.

• Upper ball is seated and material above piston ball cage (black ar-

rows) fills the cavity left by the plunger and the excess is forced

through material outlet.

• As piston moves up, suction created lifts lower ball from seat and

suction tube is filled with more material (white arrows).

DOWNSTROKE

AIR MOTOR:

• Compressed air above air motor piston forces it down.

• Air below piston is exhausted.

LOWER PUMP END:

• Pistongoes downcausing lowerballtoseat.Materialinsuction tube

(whitearrows) forcestheupperball fromseatandflows throughpis-

ton ball cage to the upper portion of the suction tube.

• Plungerenterssuction tubecausingdisplacementofmaterial(black

arrows) through material outlet.

TROUBLE SHOOTING

PROBLEM

• Air leakage out of slots in (3) spacer tube.

CAUSE

• Worn lower air motor packings.

REMEDY

• Replace packings (see figure 4).

PROBLEM

• No material (stalled pump).

CAUSE

• Obstructed material line.

REMEDY

• Remove obstruction.

PROBLEM

• No material (pump continually cycles).

CAUSE

• Empty material supply.

REMEDY

• Disconnect the air. Replenish material supply. Connect the air.

CAUSE

• Pin (F) disassembled from air motor piston rod.

REMEDY

• Reconnect air motorpiston rod to (1)pump rod with (F)pin. Secure

(F) pin with (G) retaining ring.

PROBLEM

• Material on one stroke only (fast downstroke).

CAUSE

• (24) ball in (26 or 27) seat is not seating.

REMEDY

• Remove the foot valve. Clean and inspect ball and foot valve. If ei-

ther ball or foot valve is damaged, replace.

PROBLEM

• Material on one stroke only (fast upstroke).

CAUSE

• Worn (17) cup.

REMEDY

• Replace with new (17) cup.

PROBLEM

• Material leakage out slots in (3) spacer tube.

CAUSE

• Worn (8 or 9) packings.

REMEDY

• Replace with new (8 or 9) packings.