2 MDrive17Plus Microstepping REV060208

Holding Torque Detent Torque Rotor Inertia Weight (Motor+Driver)

SINGLE LENGTH

32 oz-in / 22.6 N-cm 1.66 oz-in / 1.17 N-cm 0.00053

oz-in-sec

2

/ 0.038

kg-cm

2

10.4 oz / 294.8 g

DOUBLE LENGTH

60 oz-in / 42.4 N-cm 2.08 oz-in / 1.47 N-cm 0.00080

oz-in-sec

2

/ 0.057

kg-cm

2

12.0 oz / 340.2 g

TRIPLE LENGTH

74.9 oz-in / 52.9 N-cm 3.47 oz-in / 2.45 N-cm 0.00116

oz-in-sec

2

/ 0.082

kg-cm

2

15.2 oz / 430.9 g

MDrive

17Plus

MICROSTEPPING

INPUT VOLTAGE (+V)

Range

+12 to +48 VDC

Power supply current requirements = 2A (maximum) per MDrive17Plus.

Actual power supply current will depend on voltage and load.

ISOLATED INPUT

Universal

Voltage Range: +5 to +24 VDC Sourcing or Sinking

Step Clock, Direction and Enable

Differential

Voltage Range: +5 VDC

Clockwise and Counterclockwise

MOTION

Digital Filter Range 50 nS to 12.9 µS (10 MHz to 38.8 kHz)

Clock Types Step/Direction, Quadrature, Step Up/Step Down, Clockwise/Counterclockwise

Step Frequency 2 MHz Default / 5 MHz Max

Resolution

Number of Settings 20

Steps Per Revolution

200,

400, 800, 1000, 1600, 2000, 3200, 5000,

6400, 10000, 12800, 20000, 25000, 25600,

40000, 50000, 51200, 36000 (0.01 deg/µstep),

21600 (1 arc minute/µstep), 25400 (0.001mm/µstep)

THERMAL

Operating Temperature

Heat Sink –40° to +85°C (non-condensing)

Motor –40° to +100°C (non-condensing)

STANDARD SPEC I FI CA TIONS

SETUP PARAMETERS

Function Range Units Default

MHC

Motor Hold Current 0 to 100 percent 5

MRC

Motor Run Current 1 to 100 percent 25

MSEL

Microstep Resolution

1, 2, 4, 5, 8, 10, 16, 25, 32, 50, 64, 100,

108, 125, 127, 128, 180, 200, 250, 256

µsteps per full step 256

DIR

Motor Direction Override 0/1 — CW

HCDT

Hold Current Delay Time 0 or 2–65535 mSec 500

CLK TYPE

Clock Type Step/Dir, Quadrature, Up/Down, CW/CCW — Step/Dir

CLK IOF

Clock and Direction Filter

50 nS to 12.9 µS

(10 MHz to 38.8 kHz)

nS ( MHz) 200 nS (2.5 MHz)

USER ID

User ID Customizable 1–3 characters IMS

EN ACT

Enable Active High/Low — High

Optional encoder cables are available.

MOTOR SPEC I FI CA TIONS

All parameters are set using the supplied IMS SPI Motor Interface GUI and may be changed on-the-fl y.

An optional Communication Converter is recommended with fi rst orders.

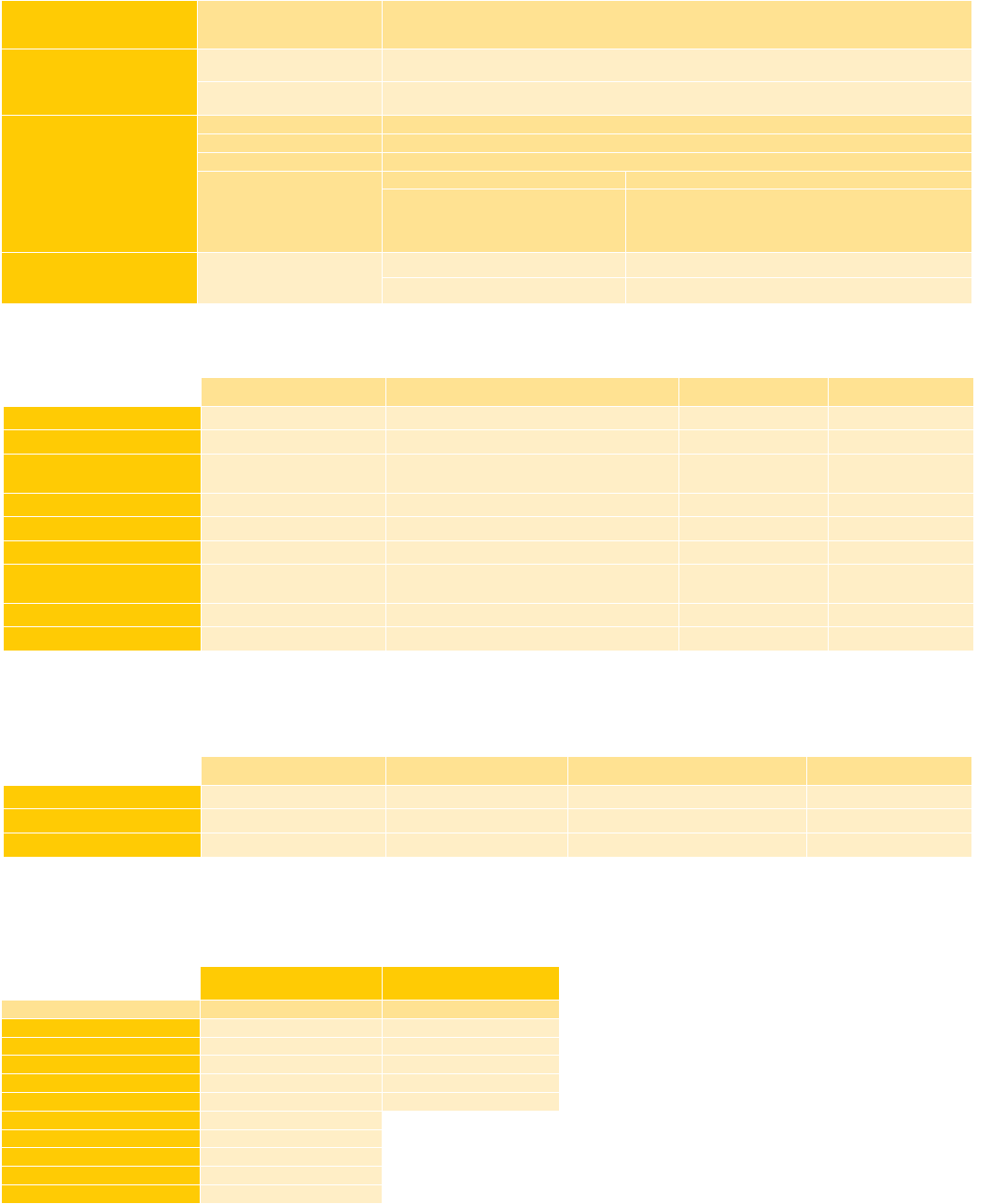

ENCODER PIN ASSIGNMENTS

DIFFERENTIAL ENCODER

with locking connector feature

SINGLE-END ENCODER

Pluggable Interface Function Function

Pin 1

No Connect Ground

Pin 2 +5 VDC Input Index

Pin 3 Ground Channel A

Pin 4 No Connect +5 VDC Input

Pin 5 Channel A – Channel B

Pin 6 Channel A +

Pin 7 Channel B –

Pin 8 Channel B +

Pin 9 Index –

Pin 10 Index +

Internal EncoderExternal Encoder

An internal differential encoder option is available on

MDrive17Plus Microstepping regular and IP65 sealed

versions.

See Wire/Pin Assignments on the following page for

connection details.