104

Sensory testing

Body Odor

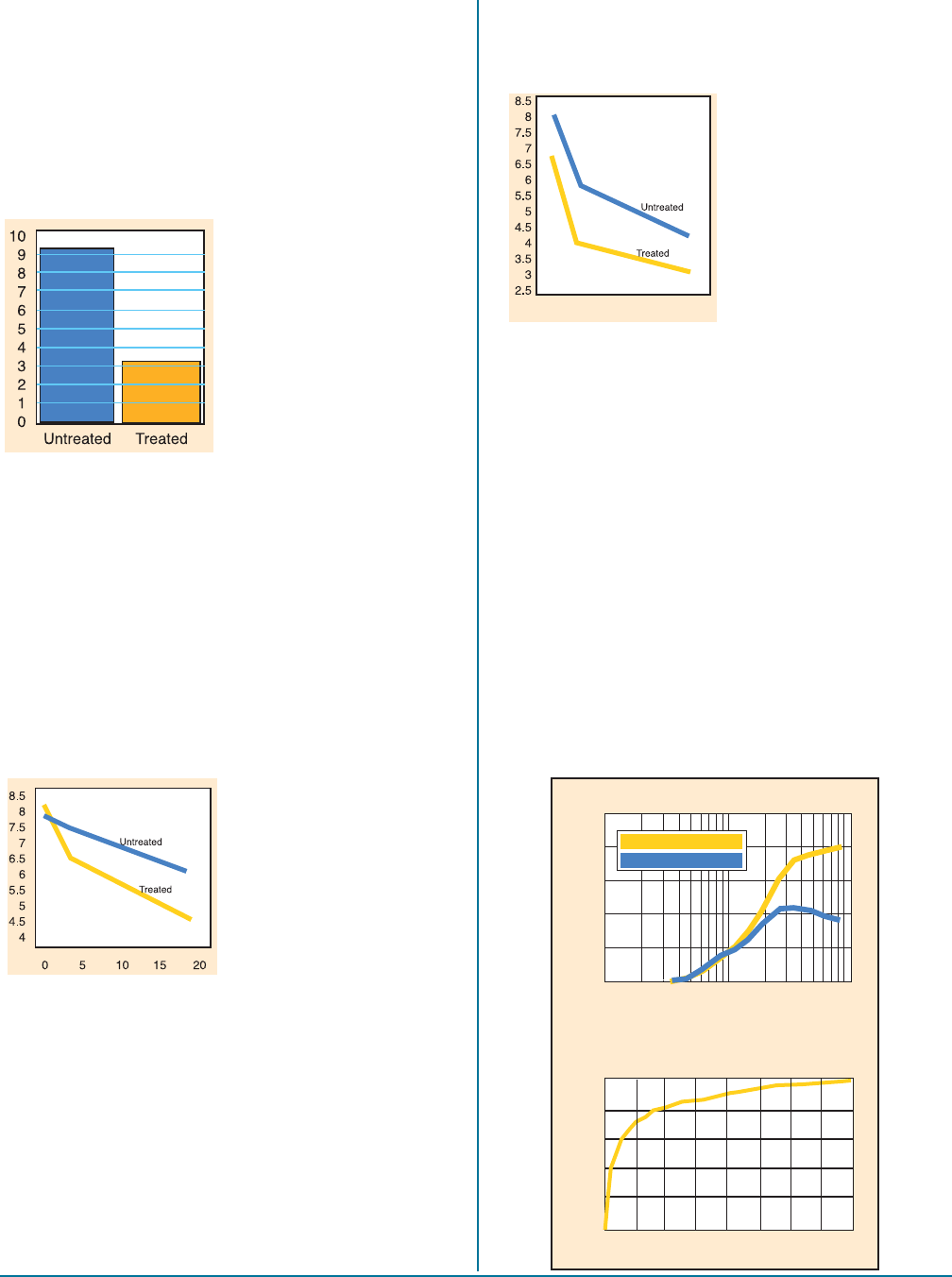

Odor level testing was conducted in jars set up spe-

cially for headspace odor

testing. Sensory evalua-

tion was run 20 hours

after the jars had been

set up to allow for ade-

quate equilibration. 20

panelists participated in

headspace odor level

testing. The malodor in

the headspace was iso-

valeric acid vapor

(Synthetic Sweat Odor)

that had passed through the filter material.

Untreated filter media was tested vs filter media

treated with baking soda. The chart shows the

average odor levels reported by panelists. A 1 to 10

scale was used, where 1 is no malodor and 10 is

extreme malodor. The difference in scores was sta-

tistically significant at the 99% confidence level.

Strong Food Odor

Deodorization testing was run in sensory rooms. In

each room, a malodor source consisting of 100

grams of sauerkraut was placed behind a 20”x20”

box fan which recirculated the air. Attached to the

outlet of each fan was a

20”x20” filter. A filter

treated with baking soda

was attached to one and

an untreated filter

attached to the other.

The graph here illus-

trates results as rated by

20 panelists. Levels of

odor were rated on a 1 to

10 scale. Initially (after 1

hour), both rooms showed a high level of malodor.

As time passed, the room with the baking soda

treated filter generated lower odor scores. The 18

hour score is statistically significant at the 90% con-

fidence level.

Urine Odor

Cat urine was tested

using the same appara-

tus and method as the

sauerkraut test. The

odor source was a 6”x6”

carpet swatch that had

been sprayed with 0.70

grams of cat urine. The

chart at left shows the

perceived odor levels in

the rooms. The differ-

ences in score for hours

1 and 5 are statistically significant at the 90% con-

fidence level.

Media specification

The filter media shall be manufactured using fine

grain sodium bicarbonate (baking soda) at a rate of

2 grams per square foot of media. The baking soda

will be uniform through the thickness of the media.

A majority of individual media fibers will be coated

with the fine-grained baking soda. The sodium

bicarbonate coating will be adhered to the fibers.

Proof of fiber coating and uniformity through the

media is to be given in the form of electron micro-

scopic photographs. The media will have a mini-

mum SO2 efficiency of 40% at one hour when test-

ed at the National Ambient Air Quality Standard

(NAAQS) at 1000 cfm.

051015 20 25

2.5 g Filter Tested at 0.15 ppm SO

2

at 1000 cfm, 72º F, 62% RH

Fractional Penetration

024 6810121416

Time (H)

1

0.8

0.6

0.4

0.2

0

0.1 1 10

100

80

60

40

20

0

Fractional Efficiency (%)

Fractional Efficiency vs. Particle Diameter

Particle Diameter

PH Odor Control Pleat

Standard 30% Pleat

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store