308350 17

Service

CAUTION

To reduce the possibility of costly damage to the

rod (1) and cylinder (2), always use a plastic or

wooden block to help drive the rod out of the cylin-

der. Never hit the rod with a hammer.

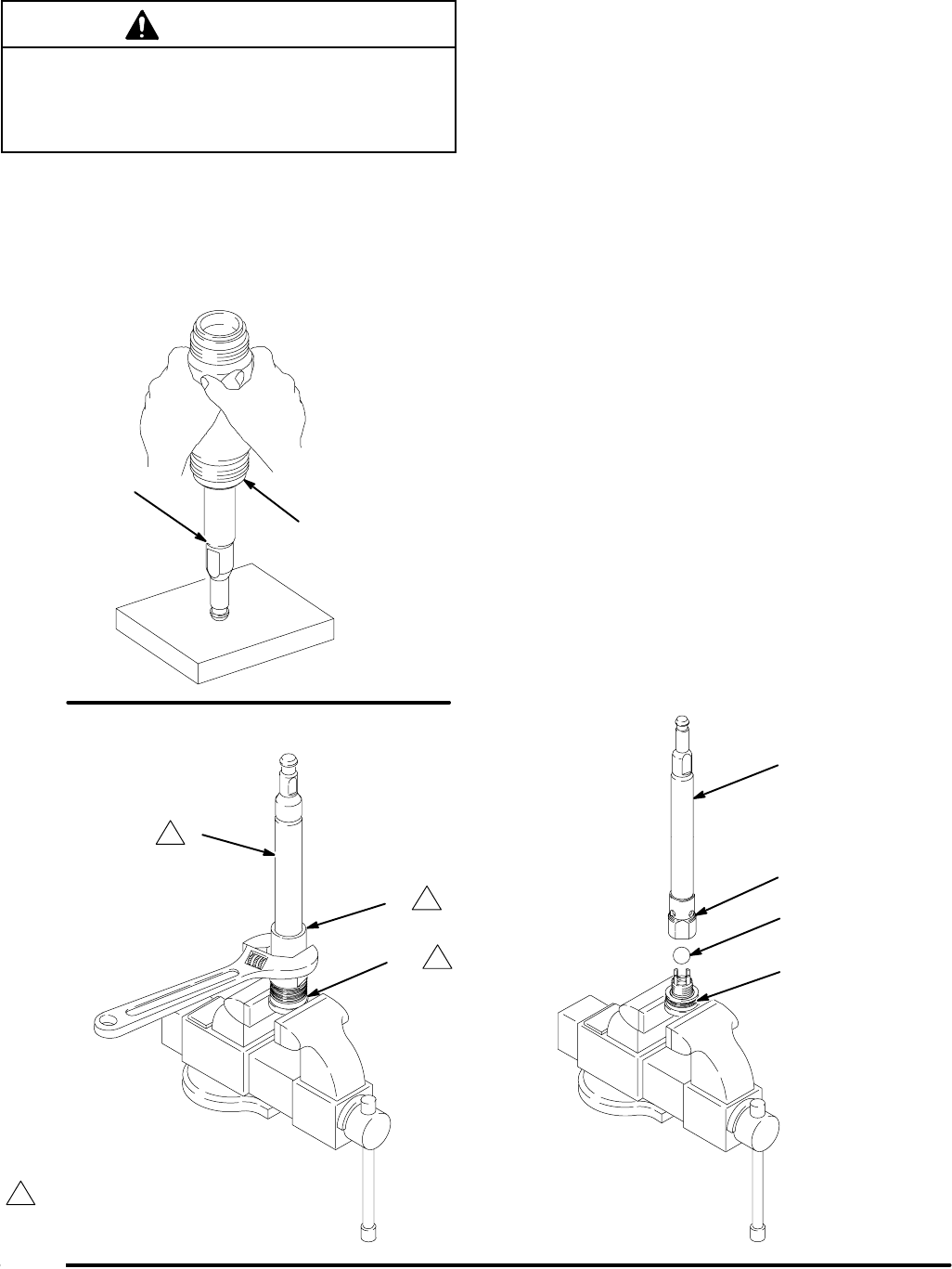

5. Turn the cylinder (2) upside down and strike the

top of the rod (1) on a plastic or wooden block until

the piston comes free. Pull the rod and piston from

the cylinder, being careful not to scratch the parts.

See Fig. 6.

04518

Fig. 6

1

2

6. Shine a light into the cylinder (2) to inspect the

inner surface for scoring or wear. Remove the two

seals (11) from the cylinder.

7. Place the flats of the piston seat housing (10) in a

vise, as shown in Fig. 7.

8. Using an adjustable wrench, unscrew the piston

ball housing (9) from the piston seat housing. Be

careful to catch the piston ball (12) as you sepa-

rate the piston seat housing and ball housing, so

that it does not fall and suffer damage.

9. Examine the displacement rod (1) for scratches or

other damage. Only if the rod needs replace-

ment, place the piston ball housing (9) in a vise

and unscrew the rod, using an adjustable wrench

on the flats of the rod.

10. Remove the glands and v-packings (P) and the

ball (12) from the piston seat housing (10). Inspect

the ball seat (E) and ball guides (F) for wear or

damage. See Fig. 9.

11. Unscrew the packing nut (8) from the outlet hous-

ing (6). Remove the glands and v-packings (T).

See Fig. 9.

12. Clean all parts with a compatible solvent and

inspect them for wear or damage.

0449404495

Fi

g

. 7

1

9 1

1

9

1

12*

10

10 1

1

Torque to 258–285 NSm (190–210 ft–lb).