11307160

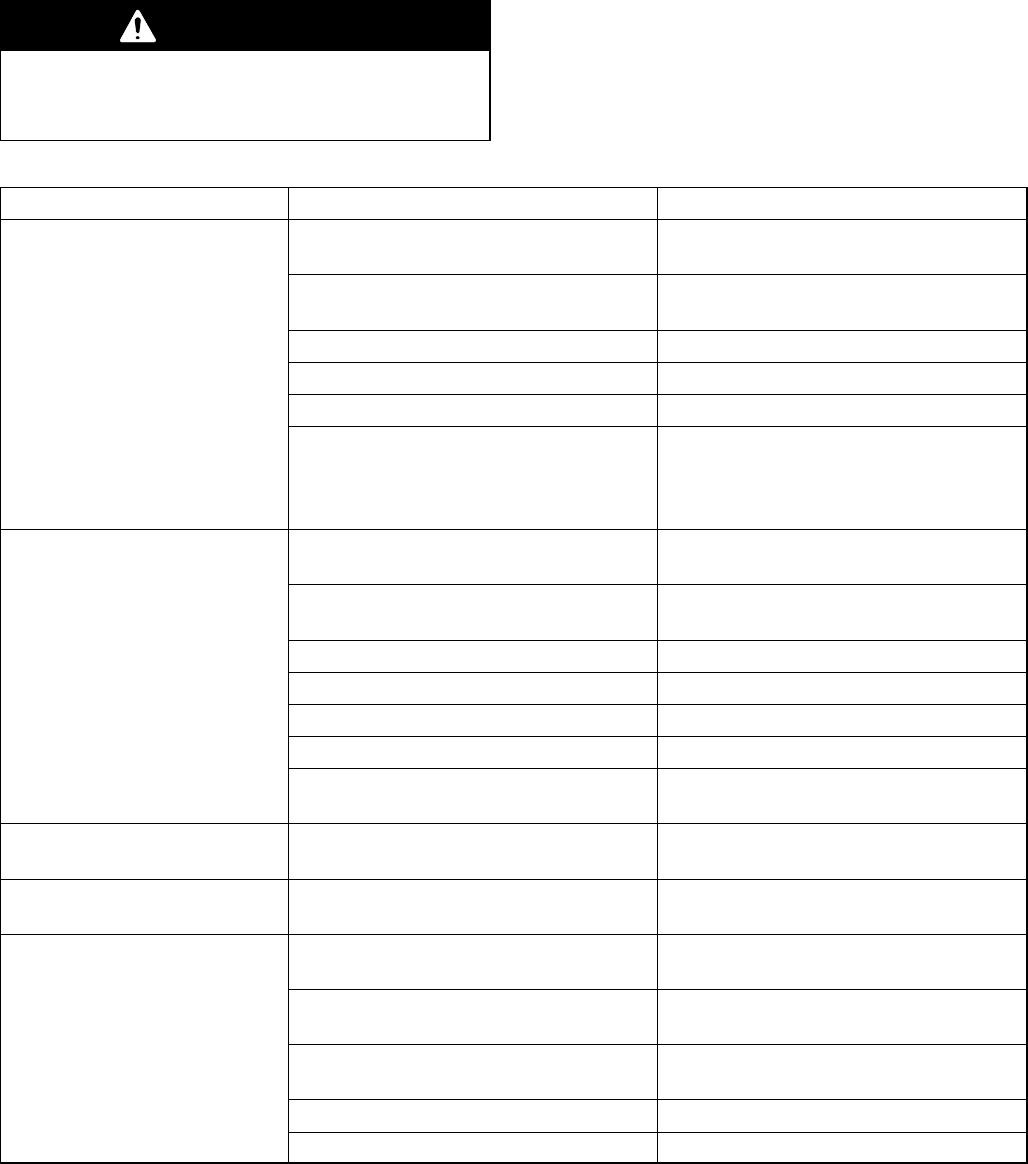

Troubleshooting

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

Before servicing this equipment, always make sure to

relieve the pressure.

NOTE: Check all possible problems and solutions

before disassembling the pump.

Problem

Cause Solution

Pump fails to operate Restricted lines or inadequate hydraulic

supply

Clear lines. Increase hydraulic supply.

Insufficient hydraulic pressure; closed

or clogged valves, etc.

Open; clean.

Exhausted fluid supply Refill and reprime, or flush.*

Clogged fluid line, valves, etc. Clear.**

Damaged hydraulic motor Service the motor. See manual 307158

Dried fluid seizure of displacement rod. Clean. See Displacement pump manual

308043. ALso, keep TSL in the pump

wet-cup and stop the pump at the bot-

tom of its stroke during non-use.

Pump operates, but the fluid

output is low on both strokes

Restricted lines, or inadequate hydrau-

lic supply

Clear lines. Increase hydraulic supply.

Insufficient hydraulic pressure; closed

or clogged valves, etc.

Open; clean.

Exhausted fluid supply Refill and reprime or flush.*

Clogged fluid line, valves, etc. Clear.**

Piston check valve needs adjustment Adjust. See manual 308043.

Packing nut too tight Loosen.

Loose packing nut or worn throat pack-

ings.

Tighten packing nut or replace packings

as needed, See manual 308043.

Pump operates, but the output

is low on the downstroke

The intake valve is stuck open or worn. Clear; service. See manual 308043.

Pump operates, but the output

is low on the upstroke

The piston valve is stuck open, or the

packings are worn

Clear; service. See manual 308043.

Pump is operating erratically,

or speeds up suddenly

Exhausted fluid supply Refill and reprime or flush.*

The intake valve is stuck open or worn Check; replace parts as needed. See

manual 308043.

The piston valve is stuck open or the

packings are worn.

Check; replace parts as needed. See

manual 308043.

Excessive hydraulic fluid supply volume Lower volume.

Air entrained in fluid Purge all air; change fluid.

* Stop the pump immediately if it is running too fast; check the fluid supply. If empty, refill and reprime the pump

being sure to eliminate all air from the system, or flush the pump and store it with an oil-based solvent, such as

mineral spirits, to prevent corrosion.

** Relieve the pressure, and then disconnect the fluid line. If the pump starts when the hydraulic power is re-

stored, line, etc. is clogged.