Wiring

All field wiring should be routed up through the knockout

in the bottom panel or in the back of the unit.

Supply Power.

1. Insure that minimum circuit ampacity is 15 amps.

2. Terminals are provided in the electrical compartment

for field connection of the main power supply legs

(single phase) and a ground wire.

3. Install external overcurrent protection and provide

wiring in accordance with the NEC, state and local

codes.

4. Power supply must be “clean”: free of spikes, surges

and sags: +10%, -15% of nominal.

Electrical Characteristics

Capacity Steam Output

Lbs. / hr 4 8

Kg / hr 1.8 3.7

Input kW

1.33 2.66

Volts/Ph: Amps

120/1 11.8 N/A

230/1 5.9 11.8

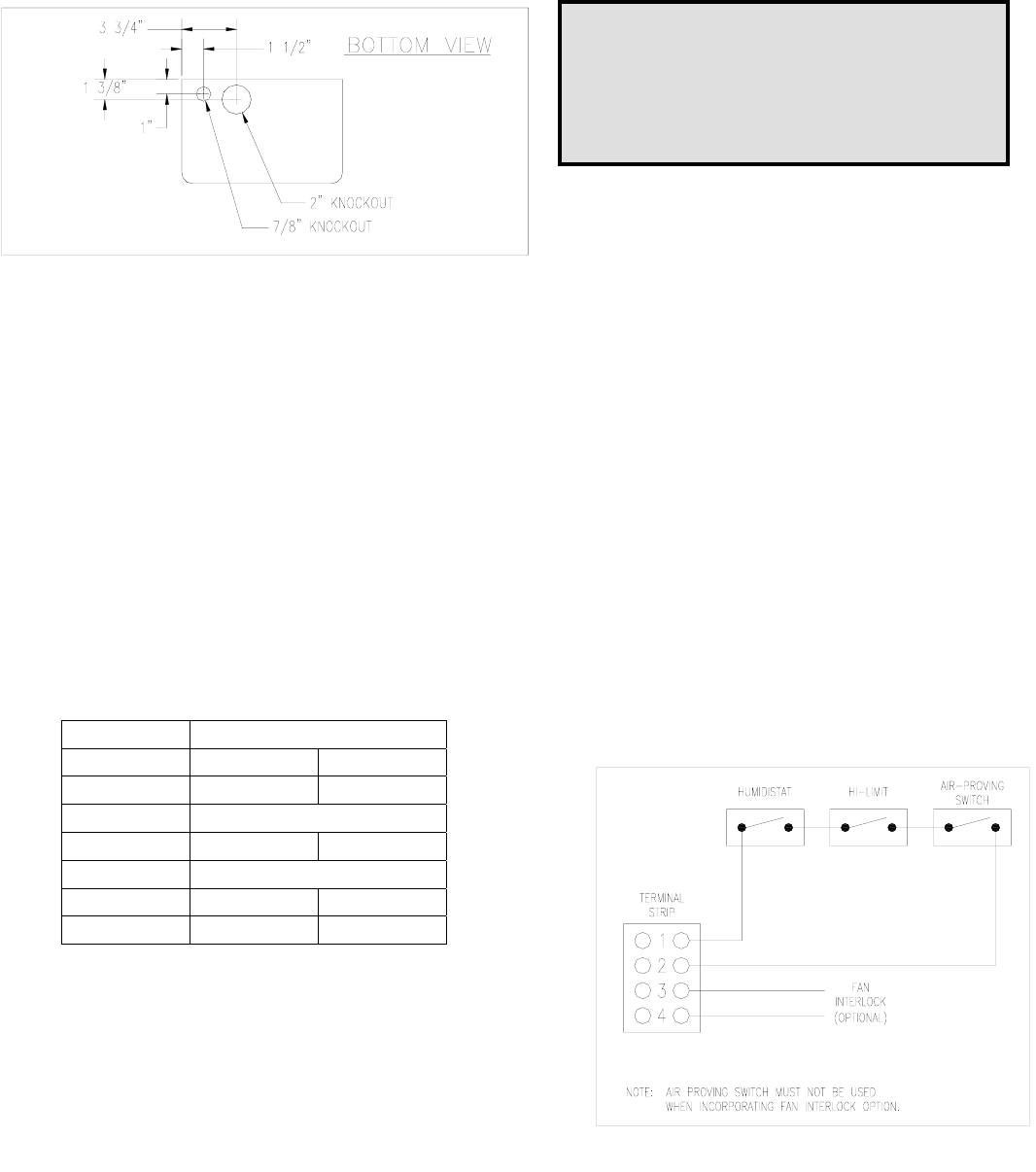

Control Circuit Connections

WARNING!

Do Not install any controls inside the

Herrmidifier 6000 cabinet. Installations of an

y

extraneous devices inside the electrical

compartment rnay cause erratic behavior of the

circuitry and will VOID the warranty.

6000-1,2

The 6000 units with built-in blowers require no external

control wiring since the humidistat and air proving switch

are built-in.

6000-3,4

The control wiring for the ducted version is to be

connected to the 5 pole controls terminal strip located in

the low voltage compartment. Terminals #1 and #2 are

for connecting the control and high limit humidistats as

well as the air proving switch in series (all included). If

desired, terminals #3 and #4 are relay contacts to

energize your fan relay (Relay contact rating 12 Amps at

125 VAC, 8 Amps at 250 VAC). With this optional wiring,

on a call for humidity, the humidifier will close the

interlock relay and energize the fan blower. The air-

proving switch must not be used if the fan interlock

is utilized. All control wiring should be 22 AWG or larger

(See figure 8). Consult with the factory if you have any

special wiring requirements.

Figure 7

Figure 8

9