SECTION VI SUGGESTED SPECIFICATIONS

Suggested Specifications

Part I-Scope

• Furnish a system of humidification for the areas known as______________________________________.

• Operation of the system shall be controlled automatically to maintain _____%R.H. at_____ (F with a tolerance of +/-

______%R.H.

• Warrant the system for a period of two years from date of shipment (except for the replaceable steam cylinder).

• Provide (1) owner's manual to cover installation, start-up, operation and maintenance.

Part II -Scope

• Furnish self-contained electrode steam humidifier(s) with a capacity of lbs./hr. with a power supply of ____V/Ph/Hz.

The humidifier shall be capable of operating on water of 60-1000 micromho. The equipment shall be supplied per the

schedule on the drawings. The humidifier shall be Model 6000-_____as manufactured by Herrmidifier Company, Inc.,

Lancaster, PA.

• Units shall have a replaceable sealed steam cylinder with zinc plated electrodes with a published cylinder life based

on incoming water conductivity.

• Water make-up system shall include inlet strainer, solenoid valve with flow regulator, and fill tee with built-in air gap to

prevent back siphoning.

• Drain system shall consist of a silent operating DC valve, with shielded core dry operator, and integral air gap to

comply with state and municipal codes.

• Steam distribution system shall be:

• Integral housed blower to discharge steam directly into room without mineral dust can-over. Units shall have

integral air proving switch and time-delay included to insure proper distribution of steam.

OR

• Ducted application shall distribute steam via a stainless steel distribution pipe constructed to allow application

in horizontal or vertical mounting position. Steam pipe shall be built with an integral pitch to allow any

condensate to drain back to the cylinder.

• Unit shall include solid state control, which automatically adapts to incoming water to optimize operation of the steam

cylinder. Control shall sense high water level via a probe and modify operation when this level is reached. Control

shall provide drain tempering by mixing cool fill water with hot drain water to allow use of PVC drain lines. Fault

conditions detected by control shall be “overcurrent," “fill system," and “end of cylinder life.”

• Circuitry shall include "capacity adjustment" potentiometer to allow capacity to be adjusted from 50- 100% of factory

set maximum.

• Indicator lights shall include “Power On,” “Cylinder Full,” and “Service.”

• Unit shall have a cover interlock safety switch.

• Enclosure to be 18-gauge powder coated steel, contoured to conceal all service piping connections.

• The humidifier shall be controlled by a 24 VAC on/off humidistat. Blower version shall have integral humidistat and air

proving switch. Ducted versions shall have remote mounted control and high limit humidistats and air proving switch.

• The humidifier shall have a built-in contractor to break power to all electrodes when humidity level is satisfied.

• The unit shall be UL and CUL listed.

Part 3 -- Execution

• The humidifier shall be wall mounted. The installation shall be in accordance with the manufacturer’s instructions.

Special consideration must be given to clearances to insure adequate space for absorption of vapor into the room or

duct, whichever may apply.

• Provide water supply within pressure and conductivity criteria. Softened water is acceptable.

• Provide unit drain.

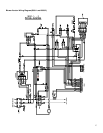

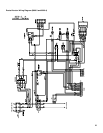

• All wiring shall be in accordance with applicable sections of national, state and local electrical codes. The contractor

shall provide and install external overcurrent protection and install system wiring in accordance with the

manufacturer's requirements.

23