2

GENERAL INFORMATION

១ A fireplace screen must be in place when logs are operating and, unless other provisions for combustion air are

provided, the screen must have an opening(s) for the introduction of combustion air.

១ If glass doors are used with this log set, open doors fully when unit is operating.

១ Open damper according to the chart on page 3 of these instructions (or fully open) and be sure damper stop clamp is

installed. (See damper stop instructions listed on page 5.) Gas supply pipe must be 1/2” minimum I.D. or larger

(3/4” if gas line is longer than 20 feet). The minimum inlet gas supply pressure for the purpose of input adjustment is

7 inches for natural gas and 11 inches for LP gas. The maximum inlet gas supply pressure is 10.5 inches for natural

gas and 13 inches for LP gas.

១ Solid fuels shall not be burned in a fireplace where a decorative appliance is used.

១ The installation and provisions for combustion and ventilation air must conform with the National Fuel Gas Code,

ANSI Z223.1.

១ The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psig (3.5 kPa).

១ The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.5 kPa).

១ KEEP APPLIANCE AREA CLEAR AND FREE FROM COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

១ Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and any gas control which has been under water.

VENTING SYSTEM MAINTENANCE

An annual examination and cleaning of the venting system by a qualified person is recommended.

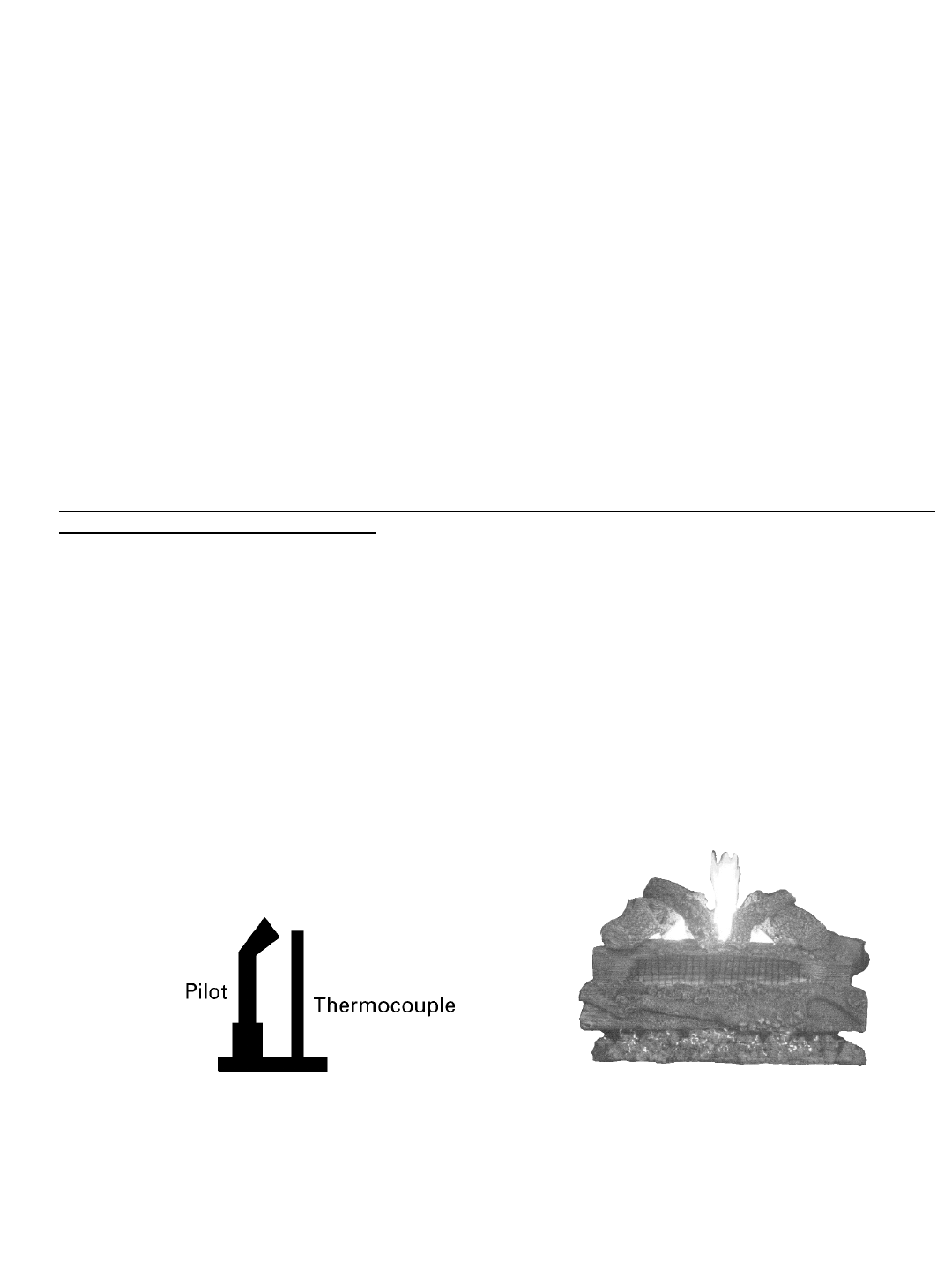

CLEANING YOUR GAS LOG SET

Periodically you may want to remove the soot build-up on the logs by lightly brushing the logs with a soft brush. Also,

occasionally, visually inspect your burner pan and pilot for proper operation (Fig. 1 and Fig. 2 below).

Fig. 1 Fig. 2